Manual Unheated - Applications for 1K High Viscosity Products

Manual Unheated - Applications for 1K High Viscosity Products

Manual Unheated - Applications for 1K High Viscosity Products

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

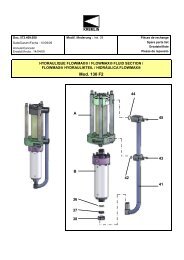

THINGS TO KNOW ABOUT SELECTING AFOLLOWER PLATEThe follower plate has three functions:• To give good positive priming to the pump, by helping the material flow towards thepump inlet,• To seal the material in the drum, in the case of moisture sensitive materials to keepout atmospheric moisture from reacting with the material, or it may just be simply toprotect the material from outside contaminants,• To give a clean wipe to the drum – to ensure that the material is dispensed from thedrum with the minimum of wastage.Drum sizes – thankfully drum manufacturers produce a standard range of sizes these days.This does not mean that very occasionally you will not get a “special” either a differentsized tapered drum or even a square drum – please consult usTypes of follower plateSingle wiper seal – Is often used on low viscosity materialssay up to 300000 cps. Can be used on tapered drums, andon non moisture sensitive materials.Double Seal follower plate PTFE coated – Is always used onhigh viscous or moisture sensitive materials where a perfectsealinterface between the drum and the follower plate isrequired.SELECTINGTHE STYLE ANDNUMBEROF SEALSPail or drum design <strong>Viscosity</strong> Sensitive tomoisture+ -Flat sealplate Double flatseal plate 57GUIDE KREMLIN FR GB DER OK.indd 57 17/05/11 09:52