Manual Unheated - Applications for 1K High Viscosity Products

Manual Unheated - Applications for 1K High Viscosity Products

Manual Unheated - Applications for 1K High Viscosity Products

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

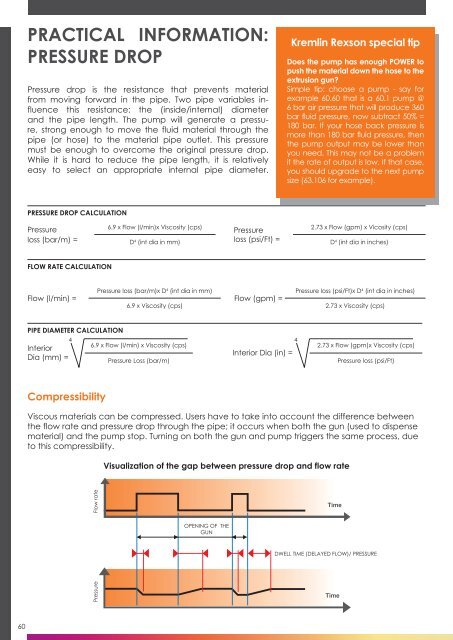

PRACTICAL INFORMATION:PRESSURE DROPPressure drop is the resistance that prevents materialfrom moving <strong>for</strong>ward in the pipe. Two pipe variables influencethis resistance: the (inside/internal) diameterand the pipe length. The pump will generate a pressure,strong enough to move the fluid material through thepipe (or hose) to the material pipe outlet. This pressuremust be enough to overcome the original pressure drop.While it is hard to reduce the pipe length, it is relativelyeasy to select an appropriate internal pipe diameter.Kremlin Rexson special tipDoes the pump has enough POWER topush the material down the hose to theextrusion gun?Simple tip: choose a pump - say <strong>for</strong>example 60.60 that is a 60.1 pump @6 bar air pressure that will produce 360bar fluid pressure, now subtract 50% =180 bar. If your hose back pressure ismore than 180 bar fluid pressure, thenthe pump output may be lower thanyou need. This may not be a problemif the rate of output is low. If that case,you should upgrade to the next pumpsize (63.106 <strong>for</strong> example).PRESSURE DROP CALCULATIONPressureloss (bar/m) =6.9 x Flow (l/min)x <strong>Viscosity</strong> (cps)D 4 (int dia in mm)Pressureloss (psi/Ft) =2.73 x Flow (gpm) x Vicosity (cps)D 4 (int dia in inches)FLOW RATE CALCULATIONFlow (l/min) =Pressure loss (bar/m)x D 4 (int dia in mm)Pressure loss (psi/Ft)x D 4 (int dia in inches)Flow (gpm) =6.9 x <strong>Viscosity</strong> (cps) 2.73 x <strong>Viscosity</strong> (cps)PIPE DIAMETER CALCULATION4 46.9 x Flow (l/min) x <strong>Viscosity</strong> (cps)InteriorInterior Dia (in) =Dia (mm) =Pressure Loss (bar/m)2.73 x Flow (gpm)x <strong>Viscosity</strong> (cps)Pressure loss (psi/Ft)CompressibilityViscous materials can be compressed. Users have to take into account the difference betweenthe flow rate and pressure drop through the pipe; it occurs when both the gun (used to dispensematerial) and the pump stop. Turning on both the gun and pump triggers the same process, dueto this compressibility.Visualization of the gap between pressure drop and flow ratePressure Flow rateOPENING OF THEGUNTimeDWELL TIME (DELAYED FLOW)/ PRESSURETime60GUIDE KREMLIN FR GB DER OK.indd 60 17/05/11 09:52