box culverts product guide - Shaw Precast Solutions

box culverts product guide - Shaw Precast Solutions

box culverts product guide - Shaw Precast Solutions

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

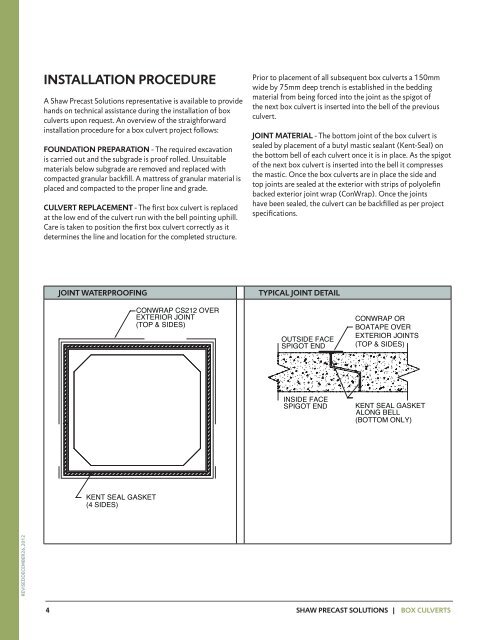

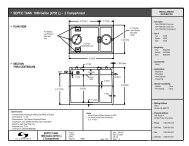

INSTALLATION PROCEDUREA <strong>Shaw</strong> <strong>Precast</strong> <strong>Solutions</strong> representative is available to providehands on technical assistance during the installation of <strong>box</strong><strong>culverts</strong> upon request. An overview of the straighforwardinstallation procedure for a <strong>box</strong> culvert project follows:FOUNDATION PREPARATION - The required excavationis carried out and the subgrade is proof rolled. Unsuitablematerials below subgrade are removed and replaced withcompacted granular backfill. A mattress of granular material isplaced and compacted to the proper line and grade.CULVERT REPLACEMENT - The first <strong>box</strong> culvert is replacedat the low end of the culvert run with the bell pointing uphill.Care is taken to position the first <strong>box</strong> culvert correctly as itdetermines the line and location for the completed structure.Prior to placement of all subsequent <strong>box</strong> <strong>culverts</strong> a 150mmwide by 75mm deep trench is established in the beddingmaterial from being forced into the joint as the spigot ofthe next <strong>box</strong> culvert is inserted into the bell of the previousculvert.JOINT MATERIAL - The bottom joint of the <strong>box</strong> culvert issealed by placement of a butyl mastic sealant (Kent-Seal) onthe bottom bell of each culvert once it is in place. As the spigotof the next <strong>box</strong> culvert is inserted into the bell it compressesthe mastic. Once the <strong>box</strong> <strong>culverts</strong> are in place the side andtop joints are sealed at the exterior with strips of polyolefinbacked exterior joint wrap (ConWrap). Once the jointshave been sealed, the culvert can be backfilled as per projectspecifications.JOINT WATERPROOFINGTYPICAL JOINT DETAILCONWRAP CS212 OVEREXTERIOR JOINT(TOP & SIDES)OUTSIDE FACESPIGOT ENDCONWRAP ORBOATAPE OVEREXTERIOR JOINTS(TOP & SIDES)INSIDE FACESPIGOT ENDKENT SEAL GASKETALONG BELL(BOTTOM ONLY)KENT SEAL GASKET(4 SIDES)REVISED December 26, 20124 SHAw precast solutions | BOX CULVERTS