Download "Predicting E. coli inactivation in uncooked comminuted ...

Download "Predicting E. coli inactivation in uncooked comminuted ...

Download "Predicting E. coli inactivation in uncooked comminuted ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

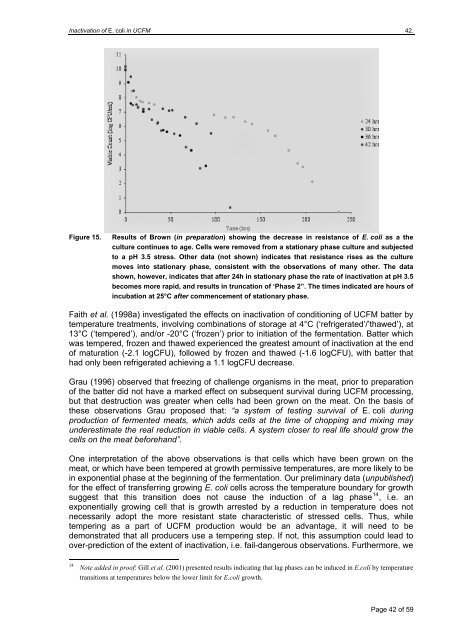

Inactivation of E. <strong>coli</strong> <strong>in</strong> UCFM 42.Figure 15.Results of Brown (<strong>in</strong> preparation) show<strong>in</strong>g the decrease <strong>in</strong> resistance of E. <strong>coli</strong> as a theculture cont<strong>in</strong>ues to age. Cells were removed from a stationary phase culture and subjectedto a pH 3.5 stress. Other data (not shown) <strong>in</strong>dicates that resistance rises as the culturemoves <strong>in</strong>to stationary phase, consistent with the observations of many other. The datashown, however, <strong>in</strong>dicates that after 24h <strong>in</strong> stationary phase the rate of <strong><strong>in</strong>activation</strong> at pH 3.5becomes more rapid, and results <strong>in</strong> truncation of ‘Phase 2”. The times <strong>in</strong>dicated are hours of<strong>in</strong>cubation at 25°C after commencement of stationary phase.Faith et al. (1998a) <strong>in</strong>vestigated the effects on <strong><strong>in</strong>activation</strong> of condition<strong>in</strong>g of UCFM batter bytemperature treatments, <strong>in</strong>volv<strong>in</strong>g comb<strong>in</strong>ations of storage at 4°C (‘refrigerated’/’thawed’), at13°C (‘tempered’), and/or -20°C (‘frozen’) prior to <strong>in</strong>itiation of the fermentation. Batter whichwas tempered, frozen and thawed experienced the greatest amount of <strong><strong>in</strong>activation</strong> at the endof maturation (-2.1 logCFU), followed by frozen and thawed (-1.6 logCFU), with batter thathad only been refrigerated achiev<strong>in</strong>g a 1.1 logCFU decrease.Grau (1996) observed that freez<strong>in</strong>g of challenge organisms <strong>in</strong> the meat, prior to preparationof the batter did not have a marked effect on subsequent survival dur<strong>in</strong>g UCFM process<strong>in</strong>g,but that destruction was greater when cells had been grown on the meat. On the basis ofthese observations Grau proposed that: “a system of test<strong>in</strong>g survival of E. <strong>coli</strong> dur<strong>in</strong>gproduction of fermented meats, which adds cells at the time of chopp<strong>in</strong>g and mix<strong>in</strong>g mayunderestimate the real reduction <strong>in</strong> viable cells. A system closer to real life should grow thecells on the meat beforehand”.One <strong>in</strong>terpretation of the above observations is that cells which have been grown on themeat, or which have been tempered at growth permissive temperatures, are more likely to be<strong>in</strong> exponential phase at the beg<strong>in</strong>n<strong>in</strong>g of the fermentation. Our prelim<strong>in</strong>ary data (unpublished)for the effect of transferr<strong>in</strong>g grow<strong>in</strong>g E. <strong>coli</strong> cells across the temperature boundary for growthsuggest that this transition does not cause the <strong>in</strong>duction of a lag phase 14 , i.e. anexponentially grow<strong>in</strong>g cell that is growth arrested by a reduction <strong>in</strong> temperature does notnecessarily adopt the more resistant state characteristic of stressed cells. Thus, whiletemper<strong>in</strong>g as a part of UCFM production would be an advantage, it will need to bedemonstrated that all producers use a temper<strong>in</strong>g step. If not, this assumption could lead toover-prediction of the extent of <strong><strong>in</strong>activation</strong>, i.e. fail-dangerous observations. Furthermore, we14Note added <strong>in</strong> proof: Gill et al. (2001) presented results <strong>in</strong>dicat<strong>in</strong>g that lag phases can be <strong>in</strong>duced <strong>in</strong> E.<strong>coli</strong> by temperaturetransitions at temperatures below the lower limit for E.<strong>coli</strong> growth.Page 42 of 59