PolyChain® GT Timing Belts - Walther Flender

PolyChain® GT Timing Belts - Walther Flender

PolyChain® GT Timing Belts - Walther Flender

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Walther</strong> <strong>Flender</strong> Gruppe<br />

PolyChain ® <strong>GT</strong> <strong>Timing</strong> <strong>Belts</strong> PAGE 13<br />

Rim flanges<br />

Rim flanges for belt guidance<br />

Poly Chain® timing belt pulley drive systems are designed with<br />

a double flanged pulley for guiding the timing belt. To reduce<br />

costs, the smaller timing belt pulley is frequently provided for this<br />

purpose.<br />

It should be noted, however, that the driven timing belt pulley<br />

should always be equipped with double flanges, since this makes<br />

it easier to guide the slack side. For very large centre distances<br />

of axes (> 8 · d) and transmission ratios of 1 : 3 or higher and for<br />

vertical shaft positions, both timing belt pulleys should have<br />

double flanges.<br />

We offer an extensive standard line of galvanized steel flanges;<br />

please use the rim flange dimensions in the following tables for<br />

your design.<br />

The rim flanges are bevelled for better guidance of the timing<br />

belt when it runs onto the pulley. Straight rim flanges sometimes<br />

have the disadvantage that, if the shaft is not aligned precisely,<br />

the belt tooth can run onto the inside edge of the flange, resulting<br />

in premature wear. Therefore, we do not recommend using straight<br />

rim flanges without a bevel.<br />

Poly Chain® 8M<br />

Number of teeth Code A (mm) B (mm) C (mm) s (mm)<br />

22 18 L 48 54 60 1.5<br />

23 14 H 47 57 63 1.5<br />

24 15 H 51 60.5 66.5 1.5<br />

25 16 H 53 64 71 1.5<br />

26 – 27 17 H 57 68 75 1.5<br />

28 – 29 18 H 60 72 79 1.5<br />

30 19 H 64 76 83 1.5<br />

31 – 32 20 H 68 79 87 1.5<br />

33 21 H 73 84 91 1.5<br />

34 – 35 22 H 76 88 93 1.5<br />

36 23 H 79 91 97 1.5<br />

37 – 38 24 H 82.5 96 103 1.5<br />

39 – 40 25 H 87 100 106 1.5<br />

41 – 42 26 H 91 105 111 1.5<br />

43 27 H 97 109 115 1.5<br />

44 – 45 28 H 99 114 119 1.5<br />

46 – 48 30 H 107 121 127 1.5<br />

49 – 51 32 H 116 129 135 1.5<br />

52 – 53 33 H 120 134 140 1.5<br />

54 – 55 34 H 126 139 146 1.5<br />

56 – 57 36 H 132 145 152 1.5<br />

58 – 61 38 H 140 154 160 1.5<br />

62 – 64 40 H 148 161 168 1.5<br />

65 – 67 42 H 156 170 176 1.5<br />

68 – 70 44 H 164 177 184 1.5<br />

71 – 73 46 H 172 186 192 1.5<br />

74 – 77 48 H 180 195 200 1.5<br />

78 – 83 L216 190 – 216 2<br />

84 – 92 L238 200 – 238 2<br />

93 L260 210 – 260 2.5<br />

94 – 99 L260 S 230 – 260 2<br />

100 – 107 L280 230 – 280 2.5<br />

xmin = 6.0 mm<br />

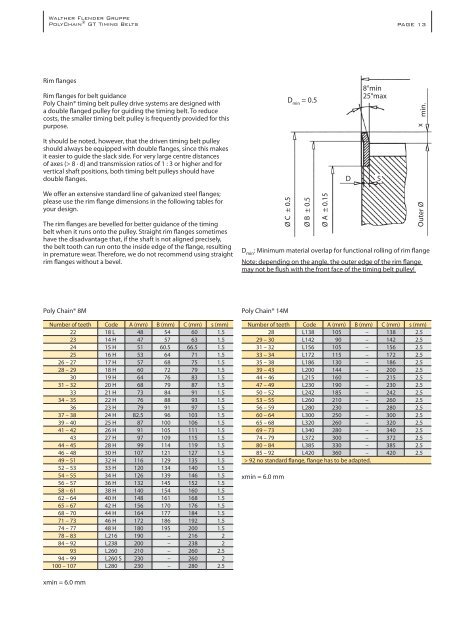

Ø C ± 0.5<br />

D min = 0.5<br />

Ø B ± 0.5<br />

Ø A ± 0.15<br />

D<br />

8°min<br />

25°max<br />

S<br />

x min.<br />

Outer Ø<br />

D min : Minimum material overlap for functional rolling of rim flange<br />

Note: depending on the angle, the outer edge of the rim flange<br />

may not be flush with the front face of the timing belt pulley!<br />

Poly Chain® 14M<br />

Number of teeth Code A (mm) B (mm) C (mm) s (mm)<br />

28 L138 105 – 138 2.5<br />

29 – 30 L142 90 – 142 2.5<br />

31 – 32 L156 105 – 156 2.5<br />

33 – 34 L172 115 – 172 2.5<br />

35 – 38 L186 130 – 186 2.5<br />

39 – 43 L200 144 – 200 2.5<br />

44 – 46 L215 160 – 215 2.5<br />

47 – 49 L230 190 – 230 2.5<br />

50 – 52 L242 185 – 242 2.5<br />

53 – 55 L260 210 – 260 2.5<br />

56 – 59 L280 230 – 280 2.5<br />

60 – 64 L300 250 – 300 2.5<br />

65 – 68 L320 260 – 320 2.5<br />

69 – 73 L340 280 – 340 2.5<br />

74 – 79 L372 300 – 372 2.5<br />

80 – 84 L385 330 – 385 2.5<br />

85 – 92 L420 360 – 420 2.5<br />

> 92 no standard flange, flange has to be adapted.<br />

xmin = 6.0 mm