PolyChain® GT Timing Belts - Walther Flender

PolyChain® GT Timing Belts - Walther Flender

PolyChain® GT Timing Belts - Walther Flender

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Walther</strong> <strong>Flender</strong> Gruppe<br />

PolyChain Page<br />

® <strong>GT</strong> <strong>Timing</strong> <strong>Belts</strong> PAGE 07<br />

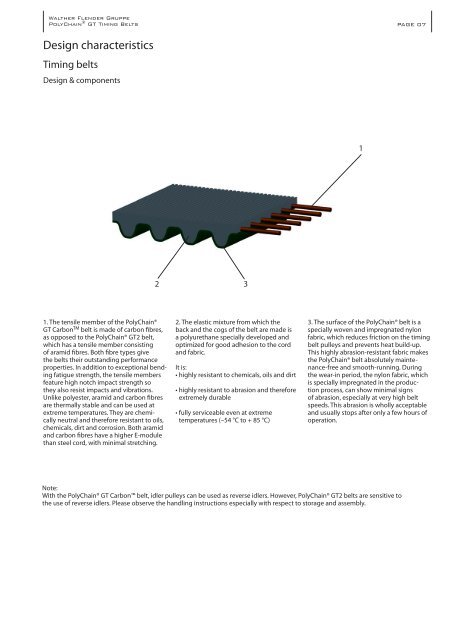

Design characteristics<br />

<strong>Timing</strong> belts<br />

Design & components<br />

1. The tensile member of the <strong>PolyChain®</strong><br />

<strong>GT</strong> Carbon TM belt is made of carbon fibres,<br />

as opposed to the <strong>PolyChain®</strong> <strong>GT</strong>2 belt,<br />

which has a tensile member consisting<br />

of aramid fibres. Both fibre types give<br />

the belts their outstanding performance<br />

properties. In addition to exceptional bending<br />

fatigue strength, the tensile members<br />

feature high notch impact strength so<br />

they also resist impacts and vibrations.<br />

Unlike polyester, aramid and carbon fibres<br />

are thermally stable and can be used at<br />

extreme temperatures. They are chemically<br />

neutral and therefore resistant to oils,<br />

chemicals, dirt and corrosion. Both aramid<br />

and carbon fibres have a higher E-module<br />

than steel cord, with minimal stretching.<br />

2 3<br />

2. The elastic mixture from which the<br />

back and the cogs of the belt are made is<br />

a polyurethane specially developed and<br />

optimized for good adhesion to the cord<br />

and fabric.<br />

It is:<br />

• highly resistant to chemicals, oils and dirt<br />

• highly resistant to abrasion and therefore<br />

extremely durable<br />

• fully serviceable even at extreme<br />

temperatures (–54 °C to + 85 °C)<br />

3. The surface of the <strong>PolyChain®</strong> belt is a<br />

specially woven and impregnated nylon<br />

fabric, which reduces friction on the timing<br />

belt pulleys and prevents heat build-up.<br />

This highly abrasion-resistant fabric makes<br />

the <strong>PolyChain®</strong> belt absolutely maintenance-free<br />

and smooth-running. During<br />

the wear-in period, the nylon fabric, which<br />

is specially impregnated in the production<br />

process, can show minimal signs<br />

of abrasion, especially at very high belt<br />

speeds. This abrasion is wholly acceptable<br />

and usually stops after only a few hours of<br />

operation.<br />

Note:<br />

With the <strong>PolyChain®</strong> <strong>GT</strong> Carbon belt, idler pulleys can be used as reverse idlers. However, <strong>PolyChain®</strong> <strong>GT</strong>2 belts are sensitive to<br />

the use of reverse idlers. Please observe the handling instructions especially with respect to storage and assembly.<br />

1