and Printing

Super Fibers - A. Venturi

Super Fibers - A. Venturi

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

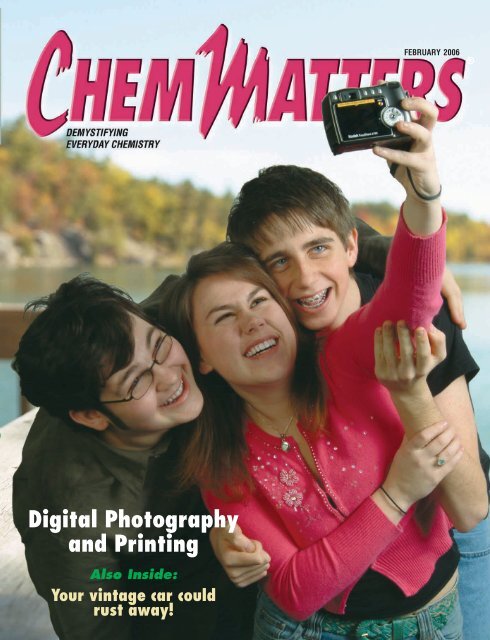

FEBRUARY 2006®Digital Photography<strong>and</strong> <strong>Printing</strong>Also Inside:Your vintage car couldrust away!

Production TeamKevin McCue, EditorCornithia Harris, Art DirectorLeona Kanaskie, Copy EditorChristen Brownlee, Contributing EditorAdministrative TeamHelen Herlocker, Administrative EditorTerri Taylor, Administrative EditorS<strong>and</strong>ra Barlow, Senior Program AssociatePeter Isikoff, Administrative AssociateTechnical ReviewSeth Brown, University of Notre DameDavid Voss, Medina High School, NYTeacher’s GuideWilliam Bleam, EditorDonald McKinney, EditorSusan Cooper, Content Reading ConsultantDavid Olney, Puzzle ContributorDivision of EducationMary Kirchhoff, Acting DirectorMichael Tinnes<strong>and</strong>, Associate Director for AcademicProgramsPolicy BoardDoris Kimbrough, Chair, University of Colorado–DenverRon Perkins, Educational Innovations, Inc., Norwalk, CTBarbara Sitzman, Tarzana, CAClaudia V<strong>and</strong>erborght, Swanton, VTSusan Gleason, Middletown, DEFrank Purcell, Classroom ReviewerChemMatters (ISSN 0736–4687) is published five times ayear (Sept., Oct., Dec., Feb., <strong>and</strong> Apr.) by the AmericanChemical Society at 1155 16th St., NW, Washington, DC20036–4800. Periodicals postage paid at Washington, DC,<strong>and</strong> additional mailing offices. POSTMASTER: Sendaddress changes to ChemMatters Magazine, ACS Office ofSociety Services, 1155 16th Street, NW, Washington, DC20036.Subscriber InformationPrices to the U.S., Canada, <strong>and</strong> Mexico: $12.00 per subscription.Inquire about bulk, other foreign rates, <strong>and</strong> backissues at: ACS Office of Society Services, 1155 16th Street,NW, Washington, DC 20036; 800-227-5558 or 202-872-6067 fax. Information is also available online athttp://chemistry.org/education/chemmatters.html.The American Chemical Society assumes no responsibilityfor the statements <strong>and</strong> opinions advanced by contributors.Views expressed are those of the authors <strong>and</strong> do not necessarilyrepresent the official position of the AmericanChemical Society. The activities in ChemMatters are intendedfor high school students under the direct supervision ofteachers. The American Chemical Society cannot be responsiblefor any accidents or injuries that may result from conductingthe activities without proper supervision, from notspecifically following directions, from ignoring the cautionscontained in the text, or from not following st<strong>and</strong>ard safe laboratorypractices.All rights reserved. No part of this publication may be reproduced,stored in a retrieval system, or transmitted in any formby any means, now known or later developed, including butnot limited to electronic, mechanical, photocopying, recording,or otherwise, without prior permission from the copyrightowner. Requests for permission should be directed in writingto ChemMatters, American Chemical Society, 1155 16th St.,NW, Washington, DC 20036–4800; 202-833-7732 fax.© Copyright 2006, American Chemical SocietyCanadian GST Reg. No. 127571347Printed in the USACOVER PHOTOGRAPHY BY MIKE CIESIELSKIQ: My parents just bought new tires fortheir car, <strong>and</strong> the salesman told them theyshould inflate them with nitrogen gasinstead of regular air. Is paying extra fornitrogen gas in car tires worth it?A: This is a very intriguing question. My initialreaction is to assume that salespeople arejust looking for one more way to squeeze abuck out of gullible customers. After all, air is78% nitrogen. Why would inflating your cartires with pure nitrogen make that big of a difference?But this question is particularly trickyfor me because it pertains to chemistry, whichI have taught for the past 22 years. And cars,though I have driven for the past 29 years, Iknow next to nothing about. I do, however,know where to go for advice about cars: thefamous Magliozzi Brothers, Tom <strong>and</strong> Ray,a.k.a. “Click <strong>and</strong> Clack, the Tappet Brothers”!(Their NPR radio show “Car Talk” is aQ uestion F rom the C lassroomBy Bob Beckerweekend favorite.)Their Car Talk website(http://www.cartalk.com) revealsthat they have addressed the nitrogenquestion quite a few times, mostrecently in April 2005. Their advice:For the average driver, filling tires withnitrogen gas is not worth the addedcost. Still, for a chemist, the “nitrogenin tires” question has an intriguing mixof silly <strong>and</strong> plausible claims swirling about it.Race car drivers do it. Why? Air containsabout 78% nitrogen, 20% oxygen <strong>and</strong>small quantities of other gases, including,most importantly, water vapor. On humiddays, air contains considerably more waterCORELvapor than it does on dry days. What's more,because of the extensive hydrogen bonding,water vapor deviates quite dramatically fromideal gas behavior. Thus, as it heats up, anair-filled tire tends to show much more inconsistencyin pressure changes than does a tirefilled with pure nitrogen gas. In car racing,contact between the tire <strong>and</strong> the track iseverything, <strong>and</strong> a fraction of a psi (poundsper square inch) in the tire can make the differencebetween winning, losing, or spinningout of control. NASCAR mechanics figuredout years ago that the pressure in a nitrogenfilledtire was far more consistent <strong>and</strong> reliablethan the pressure in air-filled tires. Does thatnecessarily mean that the average Joe orJane on the street should swap out the air intheir tires for nitrogen gas? Is it worth spendingthe extra money? Again, probably not.A large number of web sites disagree.But, consider this: These sites tend to be theones selling nitrogen. As such, the informationthey offer should be scrutinized <strong>and</strong> not merelyaccepted as factual.One argument isthat nitrogen is far lessreactive than oxygen<strong>and</strong> thus does lessdamage to the insideof the tire. This all maybe true, but it has beenmy experience that tiretreads wear off longbefore any kind ofdeterioration from the inside could make a difference.Maybe nitrogen causes less oxidationof the wheel rims? But again, is this really evenan issue?They also contend that nitrogen-filledtires dissipate heat more quickly <strong>and</strong> thus runat a lower temperature. Unless this effectcan be attributed to the water vapor, itmakes very little sense, since nitrogen <strong>and</strong>oxygen have very similar thermal conductivities(0.02583 <strong>and</strong> 0.02658 W/mKrespectively) <strong>and</strong> specific heat capacities(29.1 <strong>and</strong> 29.4 J/molK, respectively).2 ChemMatters, FEBRUARY 2006http://chemistry.org/education/chemmatters.html

®All the same, one of their more convincingarguments pertains to nitrogen's ability tomaintain tire pressure. Nitrogen reportedlyleaks out of tires more slowly than air. If youhave discussed Graham's law in chemistryclass this year, then you would probablyexpect the opposite to be true. Because nitrogenhas a somewhat lower molecular weightthan oxygen, its average molecular velocityshould be greater <strong>and</strong> it should thereforeescape or effuse through a small hole morereadily. But effusion has to do with the passingof a gas through a small opening into arelative vacuum.For the leaking out of a gas through athick permeable layer of rubber, there is somethingelse to consider. Molecular size <strong>and</strong>polarity play important roles too.Gas permeability of rubber is believed toinvolve dissolution of the gas in the polymer,diffusion through the thickness of the rubber,<strong>and</strong> loss on the other side. The N-N bond ismuch shorter than the O-O bond, <strong>and</strong> thehighest-energy electrons of O 2 are more polarizablethan for N 2 (O 2 has a higher boilingpoint than N 2 for much the same reason). Thegreater polarizability of oxygen should make itslightly more soluble than nitrogen in rubbers.(For example, oxygen is more soluble inorganic solvents than is nitrogen.)This would mean that a nitrogen-filled tireshould hold its pressure longer than one filledwith air. How much longer? Here the websitesdisagreed, <strong>and</strong> it is important to note that notone of the commercial websites actually citedany scientific studies in their arguments.An issue that far outweighs the nitrogenissue is this: An estimated 80% of the tires onthe road today are not properly inflated; they’reeither underinflated or overinflated. Both conditionscan shorten the lifetime of a tire.Underinflationlowers gasmileage <strong>and</strong>over inflationcan dangerouslylowerthe amount oftraction yourcar has on theroad. Driversshould check their tire pressure every monthor so, <strong>and</strong> add or remove air as needed.MIKE CIESIELSKIMIKE CIESIELSKIMIKE CIESIELSKIVol. 24, No. 1 FEBRUARY 2006Question From the Classroom 2Is paying extra for nitrogen gas in car tires worth it?ChemSumerThe Chemistry of Digital Photography<strong>and</strong> <strong>Printing</strong> 4Once upon a time, people put stuff called film in thetheir cameras. First, they paid for it. Then they tookphotos, but couldn’t view them on a screen. No deleting,no computer editing—they paid for strangers todevelop every miserable photo, hoping that a few wereOK! So primitive! So last-century!ChemMysteryReal or Fake? The James Ossuary Case 8Is it a priceless artifact? A bone box with a controversialinscription, is put to the test—a test that includes 18 O isotopicanalysis.Super Fibers 11Carbon nanotubes could be the key to spinning the future’shottest threads.Salting Roads: The Solution forWinter Driving 14In northern parts of the United States, salt is thewinter miracle that keeps life moving. But after theice is cleared, you’ll find crystals of it on the ground orcoating the undersides of cars. What’s the chemistryinvolved?Flaking Away 17From Ferraris to Ford Pintos, nearly every car fights a losingbattle with rust.Chem.matters.links 20TEACHERS!CMFIND YOUR COMPLETETEACHER’S GUIDE FOR THIS ISSUE ATwww.chemistry.org/education/chemmatters.html.ChemMatters, FEBRUARY 2006 3

ChemSumerThe Chemistry ofDigital Photography<strong>and</strong> <strong>Printing</strong>Once upon a time, people putstuff called film in the theircameras. First, they paid for it.Then they took photos, butcouldn’t preview them on ascreen. No deleting, no computerediting—they paid strangers todevelop every miserable photo,hoping that a few were OK!So primitive! So last-century!By Brian RohrigImagine needing eight hours toMost of your family photos were probably taken thetake a single photograph! That’s how long it took old-fashioned way, with film that had to be taken to aFrench scientist <strong>and</strong> inventor Joseph Niepce to take the photo shop to be developed. There is a fascinatingworld’s first photograph in 1826. And the end result bunch of chemistry involved in this process. All photographicfilm is coated with a thindidn’t win any prizes—it was agrainy image of some buildings viewedfrom a third-floor window. We havecome a long way since then! Today, anyamateur photographer can produce aglossy full-color photo in a matter ofminutes using a digital camera <strong>and</strong>computer. In just the past 10 years, digitalphotography has taken the world bystorm, threatening to do to film whatthe DVD has done to video.The world’s first photograph!layer of a silver halide compound,such as silver bromide (AgBr).When light strikes this layer, animage is recorded on film, which ismade visible during the developingprocess. If you have ever beeninside a darkroom, you have probablyseen all sorts of mysteriouschemicals such as developers, fixers,<strong>and</strong> baths. Even if you don’t4 ChemMatters, FEBRUARY 2006 http://chemistry.org/education/chemmatters.html

quite know how it all works, you can stillappreciate the fact that a lot of chemistrygoes into developing pictures.Does digital processing mark the end ofchemistry in photography? There is actuallyplenty of fascinating chemistry going on—it’sjust on a much smaller scale.Sensing lightAll cameras work by focusing lightthrough lenses to create an image. A conventionalcamera records this image on film. A digitalcamera records thisimage on a permanent partof the camera known as asensor. A typical sensor ina digital camera measuresonly 4.4 mm × 6.6 mm.This is about the size of afingernail.Sensor technologyhas enabled manufacturersto make digital cameras sosmall they can even beincorporated into cellphones. Similar sensordevices are used in faxmachines, scanners, copymachines, <strong>and</strong> bar codereaders at the grocerycheckout.The sensor is a semiconductor.Silicon is thematerial of choice for mostsemiconductors. This isironic because siliconbarely conducts electricityat all in its pure form. Butif a small amount of impurity is added,through a process known as doping, then siliconbecomes a fair conductor of electricity.The sensor in a digital camera comprisesmany tiny semiconductors known asdiodes. Diodes allow current to flow in onedirection, but not another. Diodes are composedof two different types of doped siliconlayers s<strong>and</strong>wiched together. One type of siliconis doped with phosphorus or arsenic.Both of these elements contain five valenceelectrons. Because silicon atoms only havefour valence electrons, the doping agentsprovide the extra electrons that movethroughout the material. With its excess ofelectrons, this type of silicon is known as n-type, with the “n” referring to the negativecharge resulting from the free electrons.GETTY IMAGESAnother type of silicon isdoped with either boron orgallium, which only have threevalence electrons. These dopingagents create a deficiencyof electrons in the structure,since silicon atoms have fourvalence electrons. This electrondeficiency creates electron“holes” in the structure.Silicon doped with these deficientatoms is referred to as p-type silicon, with the “p”st<strong>and</strong>ing for the positivecharge resulting from the deficiencyof electrons.When placed together,these two types of silicon forma diode, the one-directionalconductor described above.Think of a diode as a one-waystreet for electrons. At the p-njunction, a positive chargebuilds on the n side, <strong>and</strong> a negativecharge on the p side untilthe internal electric field counteracts the tendencyof the electrons to fill the holes. Theinternal electric field then permits current topass in one direction.As more <strong>and</strong> more holes are filled with electrons, a region, neitherP nor N, forms, called the depletion zone. Holes are shown as .Electrons are shown as .PhotositesEach diode in a sensor is a photosite.Each photosite represents one picture element—betterknown as a pixel. The greaterSuperCCD SR structure diagram, one microlens, one color filter, two photodiodes per photosite.FUGIFILM ACS STAFFChemMatters, FEBRUARY 2006 5

eam projects a negatively chargedimage of whatever is to be printedonto the light-sensitive drum. Thedrum is then coated with positivelycharged toner, which is attracted tothe negatively charged image on thedrum. An analogy would be writing amessage on the outside of a coffee canwith glue, <strong>and</strong> then rolling it in flour. Theflour will stick to the glue but not to the“unglued” parts of the can.A piece of paper then passes over acharged roller, giving it an even strongernegative charge than the drum. The drumthen rolls over the sheet of paper. Thestrongly negatively charged piece of paperpulls off the positive toner from the drum.Finally, the paper passes through a pair ofheated rollers known as the fuser, whichfuses the toner to the paper. After the paperattracts the toner from the drum, a dischargelamp bathes the drum in bright light, erasingthe original electrical image.Color printers work the same way,except the above process is repeated fourtimes. Four types of toner are used: cyan(bluish), magenta (reddish), yellow, <strong>and</strong> black.By combining tiny dots of these four colors,nearly every other color can be created.A photocopier works according to thesame basic principle, except the electrostaticimage that forms on the drum is formed bybright light that reflects off the paper to becopied. The drum is manufactured with a photoconductivematerial on its surface thatmakes it sensitive to light. White areas of thepaper are reflected onto the drum. The blackink on the paper to be copied absorbs light, soparts of the drum do not receive an electricalcharge. These uncharged parts of the drumwill form the photocopy. Just like in a laserprinter, the negatively charged toner isattracted to the positively charged imageimprinted by light on the drum. A stronglypositively charged piece of paper then attractsthe toner from the drum. Your copy is completeonce it passes through the heated rollersof the fuser.Inkjet printers, as the name implies, workby spraying tiny droplets of ink onto the surfaceof the paper. Each drop is very tiny, beingonly about 50–60 micrometers in diameter. Amicrometer (m) is a thous<strong>and</strong>th of a millimeter.A human hair has a diameter ofabout 70 m. Thereare two maintypes of inkjetprinters onthe markettoday. Bubblejet printersuse heatto vaporize inkto form a bubble.Thisexp<strong>and</strong>ing bubbleforces some of theink onto the paper.When the bubble pops, a vacuum is created,causing more ink to flow from the cartridgeinto the print head. A piezoelectric printerworks using piezo crystals (such as quartz).Piezoelectric crystals generate an electric fieldwhen distorted, but conversely, they can bedistorted by an electric field. Thus, to get thenozzle to deform <strong>and</strong> eject the ink, an electricfield is applied. This electric charge causes thenozzle to vibrate, forcing ink out on the paper.Digital photos can be printed usingeither laser or inkjet printers, but inkjet printerstend to produce better quality photos. Aninkjet photo printer will generally use six colorsas opposed to the four that are normallyemployed in a color printer. Other types ofphoto printers use a dye sublimation technique.Sublimation is the process of changingphase from a solid to a gas, skipping theliquid phase altogether. Heat is used tovaporize solid dyes, which permeate thepaper before they return to the solid form.Thermal autochrome photo printers requirethe use of special paper that already containsthe ink. A print head delivers variousamounts of heat to the paper, causing variouspigments to appear.Amazingly, experts agree that digitalphotography is still in its infancy. We will noInkjet printers work by spraying tiny droplets in ink on the surface of the paper <strong>and</strong> tend to producebetter quality photos.doubt see huge advances in digital quality <strong>and</strong>convenience in the near future. Will digitalcameras completely replace conventionalcameras? There are photographers whoremain devoted to the artistic <strong>and</strong> visualeffects of developed film <strong>and</strong> darkroom processing.For most of us, it’s nice to know wehave plenty of options available for recordinglasting images of our big moments. And it’sall due to—you guessed it—chemistry!Brian Rohrig teaches chemistry at Jonathan AlderHigh School in Plain City, OH. His most recentChemMatters article “There’s Chemistry in GolfBalls” appeared in the October 2005 issue.MIKE CIESIELSKIChemMatters, FEBRUARY 2006 7

ChemMysteryReal or Fake?The James Ossuary CaseBy Lois FruenCSI (criminal scene investigation)is not limited to murder.Recently, a crime team wasassembled to examine a controversial<strong>and</strong> potentially priceless bone box <strong>and</strong>black stone tablet. Although the bonebox may have once held skeletalremains, the team was not interestedin DNA or fingerprint evidence. Theyfocused on a grimy buildup, calledpatina, on the surface <strong>and</strong> in theinscriptions of the box <strong>and</strong> tablet. Ifproven to be fake, the patina couldexpose a forgery ring that has fakedinscriptions on ancient objects foundin museums all around the world.The inscription on the bone boxclaims that it once held the bones ofthe brother of Jesus, while the tabletreports ancient repairs to Solomon’sTemple in Jerusalem. Too good to betrue? The Israel Antiquities Authoritythinks so. But what did the crimeteam find?Dr. Elizabetta Boaretto at theWeizmann Institute radiocarbon14 C–dated the tablet, using samplesof patina from the inscription. Patinais the coating that builds up onancient objects over long periods oftime. The main component of thepatina in the inscription is calciumcarbonate (CaCO 3), called calcite bygeochemists. Calcite contains carbon,which can be 14 C tested. Dr.Boaretto reported that the patinadates to 390–200 BC. This makes ittempting to declare the tablet authentic,but 14 C dating is not enough toprove it is real. Expert forgers knowthat scientists use 14 C dating toauthenticate pieces, so they concoctpatinas using ancient carbon (charcoal)found at archaeological digs.Dr. Boaretto reported that 14 C-datingthe bone box would not provide anybetter proof of authenticity than sheobtained for the tablet.Carbon DatingPlants <strong>and</strong> animals take insmall amounts the radioactiveisotope 14 C when alive. Whenan organism dies, replenishmentof 14 C stops <strong>and</strong> 14 Csteadily decreases at a knownrate. The longer the organismis dead, the less 14 C remains.One important fakery note—a pencil made yesterday froma tree cut down 2000 yearsago will appear to be 2000years old. But a tree cut downlast year will not!Above: Bone box that may have held the bones of the brother of Jesus.8 ChemMatters, FEBRUARY 2006 http://chemistry.org/education/chemmatters.html

GEOLOGICAL SURVEY OF ISRAELNext, Professor Yuval Goren at Tel AvivUniversity examined the tablet <strong>and</strong> the bonebox. He tested hardness <strong>and</strong> density <strong>and</strong> didmicroscopic analysis of the mineral composition.He determined that the tablet isgreywacke, a stone found in western Cyprus<strong>and</strong> northern Syria, not Israel. Because thetablet is supposed to be from the 9th centuryDr. Avner Ayalon from the Geological Survey of Israel examines thecontroversial bone box.BC, it seems less likely that imported stonewould have been used instead of local stone.With further investigation, Professor Gorenfound that the surface patina is a silicate thatfirmly adheres to the surface. He pointed outthat it was unlikely that a silicate patinaformed in the calcite environment ofJerusalem. Even more suspicious, the patinain the inscription is different from the surfacepatina. It is calcite <strong>and</strong> soft enough to be easilyremoved with a toothpick. This softness is ahallmark of recent patina formation. He concludedthat the inscription was added inrecent times.Professor Goren also analyzed the bonebox <strong>and</strong> determined that it was made of nativelimestone (CaCO 3)—a stone that was commonlyused to make bone boxes in the 1stcentury AD. That finding <strong>and</strong> his analysis ofthe surface patina convinced him that the boxis genuine. It was the patina in the inscriptionthat concerned him. On close inspection, hefound the inscription cut through the surfacepatina, so he was suspicious that it had beenfaked in modern times.Dr. Avner Ayalon from the GeologicalSurvey of Israel took the investigation further.Using mass spectroscopy, he analyzed theoxygen isotope composition ( 18 O) of patinafrom both the bone box <strong>and</strong> the tablet. Oxygenisotope analysis measures the ratio of 18 O to16 O in a sample, compares the ratio to a st<strong>and</strong>ard,<strong>and</strong> then expresses the finding as permil 18 O. In this notation, the lower caseGreek letter delta () signifies the relationshipbetween the measured 18 O <strong>and</strong> the 18 O foundin a st<strong>and</strong>ard. You can think of the delta valueas the number of atoms per 1000 that theheavy isotope in the sample differs from theheavy isotope in the st<strong>and</strong>ard. To calculate avalue, investigators use this formula: 18 O =⎡⎛( 18 O/ 16 O )⎢sample18⎢⎝⎜ ( O/ 16 O )⎣st<strong>and</strong>ardTo find the 18 O, Dr.Ayalon reacted samples ofpatina with phosphoric acid(H 3PO 4). This reaction producesCO 2 gas, seen in thereaction below. The CO 2 gaswas ionized in the massspectrometer, <strong>and</strong> then the➞oxygen isotopes were separated by mass by astrong magnetic field.Dr. Ayalon compared 18 O for patinason the bone box to 18 O of patinas from 1stcentury AD bone boxes that he knew wereauthentic. He found 18 O of authentic boxesThe Reason 18 O is concentratedin the calcium carbonate relativeto water is because of quantummechanical effects: The carbonatehas more vibrations whoseenergies depend on the mass ofthe oxygen atoms, <strong>and</strong> the carbonatewith the 18 O isotope haslower-energy vibrations <strong>and</strong> overallenergy. 18 O prefers to be in thecarbonate. The importance of thisenergy difference is lessened athigher temperature because it’san exothermic reaction—thereaction becomes less favorableas the temperature increases.were between –4.1 <strong>and</strong> –6.7 per mil 18 O.These matched results for surface patina onthe bone box in question. But, 18 O readingsof patina from the inscription were between–5.8 <strong>and</strong> –10.2 per mil 18 O, with all but oneof the readings falling outside of the acceptablerange. He concluded that the box itselfwas real, but the inscription was forged.Oxygen isotope analysis was the nail inthe coffin for the bone⎞ ⎤ box. It convinced Dr.Ayalon that the inscriptionwas forged. The reason⎠⎟ – 1 ⎥⎥ ⋅1000⎦ had to do with the temperatureat which the patinain the inscription formed, which he determinedfrom 18 O values. Natural calcite patinaforms in much the same way crusty scaleslowly builds up in hot-water pipes <strong>and</strong> insidekettles, sealing oxygen isotopes in as thepatina dries. The process of calcite patinationstarts when groundwater picks up CO 2 fromair trapped in soil. When this CO 2-rich3CaCO 3 + 2H 3 PO 4 ➞ 3CO 2 (g) + 3H 2 O + Ca 3 (PO 4 ) 2calcite phosphoric acidCO 2 (g) + H 2 O (1)➞➞CaCO 3 (s) + CO 2 (aq) + H 2 O (1) ➞ Ca 2+ (aq) + 2HCO 3 - (aq)calcite dissolved CO2groundwater comes in contact with calcite, itdissolves it. Although calcite is not very solublein pure water, the higher the concentrationof dissolved CO 2 in water, the more calcitewill dissolve, shifting the equilibrium tothe right.When calcite-rich groundwater isexposed to air in a burial cave, the equilibriumshifts back, releasing CO 2 gas into thecave <strong>and</strong> precipitating calcite.If the patina on the bone box is authentic,the patina could have formed in one oftwo ways. First, it could have recrystallizedfrom water that seeped into the burial cave.Water entering the burial cave would haveabsorbed CO 2 gas from the cave environment,formed a thin film of water on thebone box, <strong>and</strong> reacted with the surface.(This reaction is the same as above becausethe box is made of limestone, CaCO 3). Whenthe film of water evaporated, it would haveleft behind a white film of calcite patina onthe surface of the box. However, if the boneChemMatters, FEBRUARY 2006 9

Stone tablet that reports ancient repairs toSolomon’s Temple in Jerusalem.Next, Dr. Ayalon checked the patina onthe tablet. From the 18 O, he determined thattwo different calcite patinas had been used inthe inscription. The first gave 18 O valuesbetween –7.3 <strong>and</strong> –8.4 per mil 18 O, while thesecond had higher values between –0.9 <strong>and</strong>–1.7. Dr. Ayalon speculated that the patina wasconcocted by grinding a carbonate material likechalk with a carbonate that contained fossils.He suggested that the forger then dissolved themixture in hot water <strong>and</strong> spread it onto the surfaceof the inscription. Ms. Orna Cohen, anexpert conservator who specializes in identification<strong>and</strong> restoration of ancient patinas, concurredwith him that the patina was forged. Shereported that when the patina was removedfrom the inscription, it appeared freshly cut.Dr. James Harrell, professor ofArchaeological Geology at the University ofToledo, suggested that the low 18 O readingscould have come from a cleanser that was usedto clean the bone box. He pointed out that antiquitiesdealers <strong>and</strong> collectors often clean artifactsto increase value, <strong>and</strong> the patina in the inscription“looks <strong>and</strong> feels exactly like what one wouldexpect from a powdered cleanser”. Cleanserscontain ground-up limestone (CaCO 3) abrasives<strong>and</strong> baking soda (NaHCO 3), which serves as thecleansing agent. Both limestone <strong>and</strong> bakingsoda react with H 3PO 4 to produce CO 2 used in 18 O analysis. Intrigued, Dr. Harrell decided tohave an oxygen isotope analysis done on fourwidely used cleansers from Israel.The Georgia Center for Applied IsotopeStudies tested the four Israeli cleansers withinteresting results. Three of the four cleansersproduced results lower than the –4.1 to –6.7per mil 18 O range set by the Geological Surveyof Israel for authentic carbonate patina. And,the most popular cleanser had a 18 O of –8.5per mil, consistent with the patina in theinscription of the bone box. The low 18 O readings,which had convinced the Israel AntiquitiesAuthority that the bone box was forged, couldhave come from cleanser!Further doubt was raised by AndreLemaire of the Sorbonne in France. He suggestedthat the fluorine found in the inscriptionof the bone box could have resulted fromcleaning with tap water. He also suggestedthat fluorine might be present in patinas ofmany authentic antiquities, since the antiquitiesmay have been exposed to groundwatercontaining modern-day runoff.Recently, 13 C data for the bone box patinahave been released. 13 C is a comparison of13 C to 12 C isotopes in a sample <strong>and</strong> is determinedusing mass spectroscopy. Readings forthe surface patina on the bone box varied fromThe inscription on the bone box reads, “Ya’akov bar Yosef ahui d'Yeshua,” which translates “James, son of Joseph, brother of Jesus”.box had been buried in a shallow grave, thepatina would have precipitated directly fromthe groundwater water onto the surface of thebox by CO 2 degassing from the groundwater.In either case, if groundwater or seepagewater were cold, the patina would havecontained more 18 O than 16 O isotopes, givinghigher 18 O readings.Conversely, calcite patinas that formfrom hot groundwater have lower 18 O values.The very low 18 O readings obtained forthe patina found in the inscription of the bonebox suggest the patina formed from very hotwater. In fact, Dr. Ayalon reported that thewater temperature had to be between 40 <strong>and</strong>50° C. Because groundwater temperatures incaves <strong>and</strong> shallow graves in the Jerusalemarea are between 18 <strong>and</strong> 20° C, it would havebeen impossible for a patina with such a low 18 O values to have precipitated naturally.On the basis of this evidence, Dr. UziDahri, Deputy Director of the IsraelAntiquities Authority, declared that theinscription was a forgery. To further supporthis case, he reported that fluorine was foundin the patina in the same percentage as fluorineadded to tap water in Jerusalem to preventtooth decay. Since drinking water wasnot fluoridated until modern times, Dr. Dahriconcluded that the patina had been fakedusing modern-day tap water. Things werenot looking good for the bone box.The forgery case seemed airtight. TheIsraeli police arrested the owner of the bonebox, who is an antiquities dealer, on a chargeof knowingly conspiring with intent todefraud. And that's when things took a turn.Muddying the waters–1.2 to –7.7 per mil 13 C. However, unlike the 18 O results, the 13 C readings for the inscriptionpatina were almost identical to the valuesfor the surface patina, ranging from –1.1 to–7.4 per mil 13 C.Are the bone box <strong>and</strong> stone tablet fakes?If they are, they could expose a forgery conspiracythat has been operating for years. Infact, the Israel Antiquities Authority has warnedthat many forgeries from this conspiracy couldbe in museums in Israel <strong>and</strong> around the world.The forgery trial was scheduled to begin onSeptember 4, 2005. But, even if the defendantsare found not guilty or the case is dismissed,doubt will linger about the authenticity of thetablet <strong>and</strong> bone box. Scientists will continue todisagree about analyses <strong>and</strong> interpretations ofresults. Methods to test antiquities willimprove, <strong>and</strong> it is likely that new examinationswill be undertaken.More importantly, even if one day theinscription on the bone box were to be provenauthentic, the names James, Joseph, <strong>and</strong>Jesus were common in the 1st century AD, sothe inscription could refer to a family otherthan the biblical one. You can follow the ongoingcontroversy on the bone box by clicking onthe “Update” section at www.bib-arch.org.Lois Fruen teaches chemistry at the Breck Schoolin Minneapolis, MN. Her most recent article “LiquidCrystal Displays” appeared in the October 2005issue of ChemMatters.10 ChemMatters, FEBRUARY 2006 http://chemistry.org/education/chemmatters.html

Carbon nanotubescould be the keyto spinning the future’shottest threads.By Christen BrownleeImagine you’re a soldier of the future. Asyou scan the horizon for possible threatsto your platoon, the day heats up, but youstay cool. Tiny air conditioners placedstrategically within your shirt turn up thejuice before sweat makes its first appearance.But that’s just the start of the laundrylist of things your new st<strong>and</strong>ard-issue attiremight do.For example, sensors integrated into thefabric could take minute-by-minute healthreadings to make sure you’re fit, calm, <strong>and</strong>well hydrated. Radios woven right into thecloth might communicate your position <strong>and</strong>status back to the home base. Your camouflagecould instantly morph to hide you in anybackground, not just the usual forest greensor desert browns. All of these powerful applicationsmight be fueled by light-weight capacitors,or batteries, twisted right into thethreads. To top it all off, your shirts <strong>and</strong> pantsmight stop projectiles on their own, withoutthe help of extra bullet proof materials.Think these revolutionary duds are “missionimpossible”? Think again. Scientists arecurrently working on developing super fibersmade of powerful carbon nanotubes. Theseultra-thin threads can be less than one-tenthous<strong>and</strong>th the width of a human hair, <strong>and</strong>they come with a bevy of interesting chemicalproperties such as super strength, <strong>and</strong> superelectrical <strong>and</strong> thermal conductivity. Woveninto a fabric, these fibers could turn any articleof clothing into extraordinary wired attire.The research still has a long way to gobefore you'll be able to pick up your ownsuper shirt at the army surplus store—chemists need to work out some toughkinks in manufacturing the rightkind of nanotubes at the rightlength for these applications. Butwith the science marching swiftlyahead, an army of super-tailoredsoldiers won’t be long behind.Strong characterDespite scientists’ long-rangescheming over possible applications,carbon nanotubes are still arelatively new technology. Theywere discovered by chance in 1991by researcher Sumio Iijima atJapan-based NEC Laboratorieswhile he was examining other carbonstructures for unrelated applications.COURTESY OF OAK RIDGE NATIONAL LABORATORYIijima <strong>and</strong> his colleagues knew they hadsomething special. They immediately saw howthe structure of the tubes, which look likerolled-up chicken wire at the molecular level,gives them unique chemical features that scientistshaven’t seen in any other material.ChemMatters, FEBRUARY 2006 11

Carbon nanotube fibers are 4 times stronger than spidersilk <strong>and</strong> 17 times stronger than the Kevlar used in bulletproofvests.VANSONCOURTESY OF NASA SEM IMAGE OF CARBON NANOTUBE FIBERSJUPITERIMAGESAccording to MatteoPasquali, a chemical engineerat Rice University in Houston,TX, like every covalent networksolid, every atom in acarbon nanotube shares electronswith its neighbors.Sometimes, this propertygives them the ability to conductelectricity extremely efficiently.The tubes’ honeycomblattice <strong>and</strong> cylindrical structurealso allow them to channelheat effectively <strong>and</strong> retain theirshape.Carbon nanotubes conductheat better than anyknown material <strong>and</strong> are manytimes stronger than any knownfiber. Plus, they are extremelylightweight, making them perfectfor adding these specialqualities to other materialswithout adding extra pounds.“To some extent,” saysPasquali, “they’re the HolyGrail of fibers.” But much likethe original Holy Grail, headds, good carbon nanotubesare extremely tricky to find.When Iijima’s group discoverednanotubes, theynoticed that the tubes spontaneouslyarise from a varietyof combustion reactions.For example, nanotubesemerge everytime you light a c<strong>and</strong>le.But this run-of-the-millproduction makes nanotubesthat aren’t suitable foranything useful, says Pasquali.First, many combustionreactions produce a r<strong>and</strong>ommishmash of different nanotubestructures—the hexagonsin the tubes’chicken-wire structure may berolled up at different angles,for example, giving them differentproperties. This slipshodproduction also spewsout various assortments ofnanotube types. Single-wallednanotubes, the hose-likestructures that seem to havethe most benefits, are often mixed in withmultiwall nanotubes, which look like tubesrolled up within tubes. To get the most reliableproperties, scientists need to work witha uniform batch of tubes that perfectly matcheach other.Second, the manufacturing techniquesavailable today—such as knocking carbonoff of a surface with a laser, for example, ordischarging bits of carbon by zapping carbonrods with electricity—can only producenanotubes that are usually only a fewmicrometers long. “If you interrupt the nanotube,then you interrupt their properties,”says Ray Baughman of the University ofTexas at Dallas. The most bang for chemists’buck lies in learning how to manufactureindividual, extra-long nanotubes. However,many scientists agree that it will be a bigstretch to produce single nanotubes muchlonger than the current limits with today’stechnology.Do the twistTo get enough material forusable super fibers, scientistshave a few tricks up theirsleeves. The bestidea for now,says R.ByronPipes ofPurdue Universityin WestLafayette, IN, is to takemany short nanotubes <strong>and</strong>bundle them into yarns. Although theresulting yarn has less than 1% of the theoreticalstrength, heat conductivity, <strong>and</strong> electricalconductivity, the end product still hassome intriguing possibilities.“For many centuries, man had only discontinuousfibers at his disposal, like flax<strong>and</strong> cotton. But we’ve made yarn, rope, <strong>and</strong>cloth, twisting fibers so they becomeCOURTESY OF NATIONAL NANOTECHNOLOGY INITIATIVE12 ChemMatters, FEBRUARY 2006 http://chemistry.org/education/chemmatters.html

strong,” says Pipes. “Most people think thatif the elements aren't continuous then it’snot strong, but that's not true.”For example, Baughman <strong>and</strong> hiscoworkers have manufactured carbon nanotubeyarns by distributing billions of nanotubesinto a detergent solution. Thescientists keep the tubes from bunchingtogether by blasting the solution with highfrequencysound waves. Feeding a thinstream of the solution into a whirling bath,the scientists have twisted yarns up to 200meters long <strong>and</strong> as thickas a human hair,but muchstronger.Thesesuperfibersare 17times as tough asthe Kevlar used in bulletproof vests, <strong>and</strong> 4 times astough as spider silk—thestrongest known natural fiber.Pasquali <strong>and</strong> his colleagues are usinganother solution-based way to make theirown nanotube yarns. Dumping their individualnanotubes into sulfuric acid, theresearchers found that electrical chargeswithin the acid distributed the tubes evenlywithout the high-frequency sound waves.Pasquali’s team simply pressed the nanotubesolution through a syringe into acoagulating bath, pushing out meters ofsuper-strong nanotube cables.Next big thingResearchers are now testing the newfibers to see exactly what kind of physicalproperties they possess. If they can tweakthe properties of these yarns to even onetenthof an individual nanotube, then scientistswill be in business for a number ofopportunities.Clothes for a futuristic soldier will beonly the tip of the iceberg, says Baughman.They could play a majorpart in building strongervests for police officers <strong>and</strong>artificial muscles that twitchwith electricity. These aretwo super fiber possibilitiesthat he <strong>and</strong> his team aretalking about.Many scientists aredreaming much bigger; forexample, some researchersbelieve that an extra-longcable spun of carbon superfibers might somedaystretch all of the way tospace, tethering an orbitingspacecraft to the earth.Once the initial thin cord isestablished, a small climbingmachine couldstrengthen <strong>and</strong> thickenthe line, eventuallycreating a space elevatorthat couldcheaply carry people <strong>and</strong>equipment into space.On a more practicalnote, Pasquali thinks thatstretching electrical cablesmade of super fibers fromcoast to coast—or evencontinent to continent—might save an enormousamount of electricityaround the world. “One ofthe big problems withpower is that, for the mostpart, you can’t store it,” saysPasquali. “You continuouslyhave to produce the power that’s needed.”Right now, loads of electricity arewasted as power plants churn away throughthe night, supplying electricity for just a fewnight owls. But at night in one part of theworld, it’s daytime in another. If scientistscould move electricity instantly from onehalf of the world to another, energy production’sefficiency would dramaticallyimprove.Traditional cables won’t work for suchan expansive application—right now, theylose about 50% of the energy that’s producedthrough resistance while just movingit around. However, a cable woven of carbonsuper fibers could be a perfect fit forthe job, notes Pasquali.Some researchers believe that carbon superfibers may somedaystretch to space.Although the phenomenon has beenonly demonstrated over a distance of amicrometer, it’s an exciting result. He estimatesthat some of the applications of carbonsuper fibers could be here in a mere 10to 20 years.In the meantime, he <strong>and</strong> other carbonnanotube chemists will keep spinning longer<strong>and</strong> longer superfibers, weaving theirdreams toward reality.Christen Brownlee is a contributing editor toChemMatters. Her article “Flaking Away” alsoappears in this issue.ACS STAFFChemMatters, FEBRUARY 2006 13

GETTY IMAGESSalting RoadsTHE SOLUTIONFOR WINTER DRIVINGBy Doris R. KimbroughMost of you are probably planningto be in a car at some point thiswinter, so be sure to wear yourseatbelt, obey the speed limit,<strong>and</strong> be extra cautious in “winterdriving conditions”. It is actuallyphysics that makes being in a car on an icyroad hazardous; friction is an important part ofkeeping a car under control. However, yourstate <strong>and</strong> local transportation departmentsmake use of some pretty interesting chemistryto keep roads safer for travelers in the wintertime.In addition to plowing, one of the waysthat highway workers keep roads clear of ice<strong>and</strong> snow is by spreading salt on the roads.Even though salt can cause rust <strong>and</strong> corrosionon cars, bridges, <strong>and</strong> other parts of the highway,it more than makes up for this costlydamage by saving lives. Let’s take a look athow it works.Freezing pointdepressionPure water freezes at 0°C; adding salt towater depresses or lowers the freezing pointbelow zero. When you remove heat fromwater (or any substance), the molecules slowdown. The freezing process occurs when themolecules stop sliding <strong>and</strong> tumbling all overeach other (liquid phase) <strong>and</strong> settle into fixedpositions in a large network called a crystallattice, which is the solid phase. The moleculesare still moving, but in the solid phasethat motion involves bonds stretching <strong>and</strong>compressing or the atoms wiggling a little bit.This is called vibrational motion.When a solution of salt in water iscooled to a low enough temperature, thewater molecules begin to stick together in anorganized way to form solid crystals. Thecrystal framework tends not to include thesalt ions because the ions would disturb thisorganization. So when you cool a solutionenough, the ice crystals that start to form aremade of pure frozen water. You can actuallypurify salty water like this, by freezing a portionof the solution <strong>and</strong> washing the saltywater off of the ice crystals <strong>and</strong> then thawingthe ice to produce pure water. Eventually, ifyou cooled it enough, the whole solution willfreeze, but it does not have a sharply definedfreezing temperature. Getting the water moleculesorganized into a crystal from a solutionrequires that you remove more energy (actuallyfree energy) than if you are freezing purewater, so the water in a solution typicallydoes not start freezing until it reaches alower temperature than the normal freezingpoint. This is true of all solutions, not justthose made with water.The difference in temperature betweenwhere the pure solvent (water in our case)freezes <strong>and</strong> where the solution starts to freezeis called the freezing point depression. How low14 ChemMatters, FEBRUARY 2006 http://chemistry.org/education/chemmatters.html

GETTY IMAGESyou go depends upon what the solvent is <strong>and</strong>how concentrated the solution is. The moreconcentrated the solution, the lower the freezingpoint. This is why if you freeze a solutioncompletely, you have to keep lowering the temperature.As the pure water freezesaway from the solution, the concentrationof the solution remainingincreases. How does your Departmentof Transportation use thischemistry to keep roadways clearof snow <strong>and</strong> ice in the wintertime?Salting roadsHighway workers use salt intwo ways: 1) to melt ice that isalready on the roadway <strong>and</strong> 2) toprevent ice from forming on theroadway. The second one is a littleeasier to underst<strong>and</strong>, so we willstart there. Let’s say a snowstormis forecast for your town. Municipal workersget out <strong>and</strong> spread salt on the roads. As thestorm hits, snow starts to fall, but the roadsurface is warmer than the air, so the firstflakes melt. As they melt, the salt dissolves inthe liquid water. Now you have a solution ofsalty water, which has a lower freezing pointthan pure snow, so that even though the additionalsnow might cool the road enough to“stick” to the road surface, the temperaturewill not get cold enough to freeze the solutionthe way it could freeze pure water. In the end,the real snow removal is done by the plows,but salt plays a crucial role in preventing snow<strong>and</strong> ice from bonding to the pavement.“Hold it!” you say. Suppose the temperaturedoes get cold enough to freeze the solution.Or suppose that enough snow falls sothat the salt water solution gets too dilute towork, what happens then? In both of thosecases, snow could build up on the road. ThisSodium chloride <strong>and</strong> calcium chloride.JUPITERIMAGESMIKE CIESIELSKIis why your highway workers are out thereround-the-clock, plowing <strong>and</strong> spreading moresalt as long as the storm is in the area. Communitieswith really cold temperatures, likeparts of Canada <strong>and</strong> Alaska, where it can getto –20°C (below zero on the Fahrenheit scale),don’t even bother with salting the roads,because it doesn’t help. They typically plow offas much as they can <strong>and</strong> use gravel or s<strong>and</strong> toadd traction.How does it work if the road already hassnow or ice on it? You may have seen howspreading salt on an icy sidewalk will causethe snow or ice to melt. The very beginning ofthe melting process begins where solid icecontacts solid salt. At the surface of ice crystals,water molecules do not have the samestable arrangement they have on the interior;they are more mobile <strong>and</strong> more reactive. Sothe surface ice reacts with the surface of thesalt crystals, allowing a small amount of saltyWater freezes at lower temperatures when it issaltier. But solubility of salt in water decreaseswith decreasing temperature. So at some point, asolution is too cold to hold the salt that keeps itfrom freezing. The eutectic temperature is thelowest temperature at which a mixture of two ormore substances can stay liquefied. For a NaCl<strong>and</strong> water mixture, the eutectic temperature is–21.1 °C. For road ice, –10 °C is the practicallimit for salt.MIKE CIESIELSKI GETTY IMAGESChemMatters, FEBRUARY 2006 15

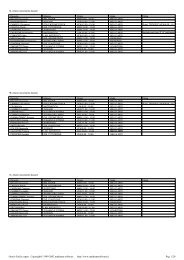

3020Phase diagram for NaClFreeze pointSalt solution-1010SolidIce +salt+-15Temp. Salt solutionSalt Temp.solution( ° F)0( ° C)-6-10-205Eutectic temperature of salt10Solid salt+ Ice23 25solution to form. This first step is relatively slow, but then the growingsolution continues to dissolve more salt <strong>and</strong> melt more ice. Passingvehicles warm the slush through friction, which speeds the dissolutionof the ice <strong>and</strong> may crush the salt <strong>and</strong> ice together, which will increasethe surface areas of the particles in contact with each other. Somecommunities use “prewetted” salt (usually rock salt with a CaCl 2 solutionsprayed on it) to speed the process.Road salt history, fun facts,<strong>and</strong> current technology1520Solution concentration (% by weight)0-5-20-21.1This phase diagram illustrates the impact of NaCl concentration <strong>and</strong>temperature on the phase of an aqueous NaCl solution.-25-30MIKE CIESIELSKIPutting salt on the roads to lessen the buildup of snow <strong>and</strong> icebegan in the 1930s, <strong>and</strong> by the 1960s, it was used by most communitieswhere snow <strong>and</strong> ice are a problem. Concerns about the effect of theuse of sodium chloride (common table salt) on the environment haveprompted some state <strong>and</strong> local road crews to explore the use of moreenvironmentally friendly salts, such as magnesium chloride <strong>and</strong> calciumchloride. These two salts have the advantage of being more effective atlowering the freezing point <strong>and</strong> there is some interestingchemistry behind this benefit.As you probably know, sodium chloride has the formulaNaCl. When it dissolves in water, it dissociates into its ions:Na + <strong>and</strong> Cl , producing two ions in solution for every NaCl formulaunit. Magnesium chloride (MgCl 2) <strong>and</strong> calcium chloride (CaCl 2)dissociate to three ions each because the metal has a 2 + charge <strong>and</strong>there are two chlorides per metal ion:MgCl 2(s) ➞ Mg 2+ (aq) + 2Cl - (aq)CaCl 2(s) ➞ Ca 2+ (aq) + 2Cl - (aq)It is the number of dissolved particles that determine the extent ofthe lowering of the freezing point of a solution. So although NaCl producestwo ions, MgCl 2 <strong>and</strong> CaCl 2 each produce three, making themmore effective. Other variations include mixtures of the magnesium <strong>and</strong>calcium chlorides, as well as magnesium <strong>and</strong> calcium acetates,Mg(C 2H 3O 2) 2 <strong>and</strong> Ca(C 2H 3O 2) 2.Practical Melt Temp. Eutectic Temp.CaCl 2 32°C 56°CMgCl 2 15°C 33°CThe technology of salting roads has become fairly sophisticated.Often, these salts are dissolved in water or some other solvent so thatthey can be sprayed onto the road surface. Having the deicing substancein a solution (i.e., fluid) form makes it possible to pump throughhoses, which allows for a more targeted application. In addition, variousanticorrosive substances are added to protect highways <strong>and</strong> cars fromthe damage the salts can cause over time. Some 15 million tons of deicingsalt is used each year in the United States <strong>and</strong> about 4–5 milliontons in Canada.You may have seen signs that warn about bridges freezing beforeroad surfaces. This is because bridges are more exposed <strong>and</strong> not insulatedby the ground from underneath like the rest of the highway. Somehigh-tech highway bridges have been constructed with deicingsprayers built right into the pavement, complete with sensors thatdetect when conditions are right (e.g., cold temperatures, high windspeeds, high humidity) for ice to form. The sensors detect the possibleformation of ice, <strong>and</strong> the deicing sprayers go to work to keep the roadwayfrom freezing.Highway engineers have been working withother interesting variations. One deicing materialthat is currently on the market mixes magnesiumchloride with sugar cane or sugar beet molasses.The sticky molasses keeps the magnesium chloridefrom getting blown or washed off the road surface.There are also substances that are added directly tothe top layer of concrete or asphalt when the road isbuilt or repaved that help prevent ice from forming.Highway workers can then get away with using less saltthan before, which is cheaper, easier on the environment,<strong>and</strong> helpful in preventing corrosion. Scientists<strong>and</strong> engineers continue to develop new ways to keepwinter highways safe while minimizing expense <strong>and</strong>environmental harm. Just another way that chemistryis keeping you out of harm’s way.Doris Kimbrough teaches chemistry at the University of Colorado-Denver. Herlast article, “Einstein’s Miraculous Year”, appeared in the December 2005 issue.16 ChemMatters, FEBRUARY 2006 http://chemistry.org/education/chemmatters.html

From Ferraris to Ford Pintos,almost every car is fightinga losing battle to rust.TBy Christen Brownleehe old-style Volkswagen Beetle: Isit a classic car, or an endangeredspecies? The answer depends onwhere you live. Although there arefew classic cars hanging aroundthe northern states or on thecoastlines, plenty of vintage automobiles stillexist in the mild southern climates <strong>and</strong> inAmerica’s interior states.The reason that Volkswagen Bugs <strong>and</strong>other older cars are dropping like flies isn’t thetypical habitat loss or human encroachmentthat's plaguing other endangered species.Classic car fleets are constantly shrinking dueto a chemical reaction that you’re no doubtalready familiar with: rusting.But why does rust unequally strike carsin the snowy states <strong>and</strong> coastal towns butleave vehicles elsewhere virtually untouched?And more importantly, how can you keepyour beloved grocery-getter safe, no matterwhat parking place you call home? Read onto get the lowdown on how rust works <strong>and</strong>what measures you can take to stop corrosionin its tracks.Electron swap meetLike all types of corrosion, rust isactually a chemical bargain, withtwo reactions in one: reduction,in which someatoms gain electrons,<strong>and</strong> oxidation, inwhich other atomslose electrons. Withall those electronsflowing from oneplace to another,rust-making is alsoconsidered an electrochemicalreaction.According to John Scully, aChemMatters, FEBRUARY 2006 17

corrosion expert at the University of Virginia inCharlottesville, the redox reaction that formsrust needs just three ingredients to take place:an anode, or metal that readily gives up electrons;a cathode, or substance (in this case,oxygen) that easily accepts electrons; <strong>and</strong> anelectrolyte solution, which shuttles ionsbetween cathode <strong>and</strong> anode.Most cars are made mostly of steel, atough mixture of iron, carbon, <strong>and</strong> smallamounts of other ingredients like manganese,silicon, phosphorus, <strong>and</strong> sulfur. It’s the ironpart of steel that corrodes to make rust.Iron doesn’t hold onto its electronsvery tightly, says Scully, making it the perfectanode for an electrochemical reaction totake place. Other metal atoms in the steelmixture, or even another point on the pieceof iron, make excellent cathodes. Steel has anonuniform surface because the chemicalcomposition is not completely homogeneous.Also, physical strains leave stresspoints in the metal. These defects createanodic regions where the iron is more easilyoxidized than it is at others (cathodicregions). However, without a bridge to connectpotential anodes <strong>and</strong> cathodes, rustingwould be such a time-consuming processthat cars would virtually last forever.The water on the steel surface is a solventfor ions produced when the iron metal atthe anodic region loses electrons (is oxidizedto form ferrous ions) <strong>and</strong> the electrons areconducted through the metal to the cathodicregion where they react with water <strong>and</strong> oxygenfrom the air to form hydroxide ions, asshown in these equations:2Fe ➞ 2Fe 2+ + 4e - (oxidation at anodic sites)4e - + O 2 + 2H 2O ➞ 4OH -(reduction at cathodic sites)The ions in this electrolyte solution canmigrate together <strong>and</strong> react to form ferroushydroxide, which reacts further with oxygenfrom the air to oxidize the ferrous ion <strong>and</strong>form insoluble ferric oxide, the chemical namefor rust, as shown in these equations:Fe 2+ + 2OH - ➞ Fe(OH) 2(formation of ferrous hydroxide)4Fe(OH) 2 + O 2 ➞ 2Fe 2O 3 + 4H 2O(oxidation to ferric oxide or red ‘rust’)The movement of ions through the electrolytesolution completes the electric circuit thatallows the electrons from iron to move fromthe anode to the cathode.A redox reaction on wheels. The bumper of this vehicle wears the product of the reaction between iron<strong>and</strong> oxygen—rust!But all this still doesn’t explain whycolder climates <strong>and</strong> coastal areas get anunfair share of rust. The magic ingredient thatboth areas share—which is missing in thebasic recipe for rust—is a high abundance ofsalt. Coastal areas have plenty of salt sailingthrough the air from ocean spray, <strong>and</strong> witheach cold, snowy winter, northern statessmear tons of rock salt on roads to lower thefreezing point of water <strong>and</strong> help keep roadsfree or ice <strong>and</strong> snow. [See “Salting Roads:The Solution for Winter Driving” in this issue]Salt speeds rust’s redox reaction alongby making water a better conductor. “Saltallows the anode <strong>and</strong> cathode to be in toucheven better,” says Scully, making corrosionhappen even quicker. Also, chloride ions formvery stable complex ions with Fe 3+ , whichhelps dissolve iron <strong>and</strong> accelerate corrosion.Costly corrosionScully points out that iron can’t helprusting—existing as an oxide in its thermodynamicallyfavored state. In fact, the metalrarely exists in a pure state in nature. Before itbecomes a side panel in your car, engineersmust convert rusty iron ore into a pure metal.With rust being iron’s favored state, it isof little use trying to fix rust after it hasalready happened. By putting energy intorust, it’s possible to plate metal back onto acar, says Scully. However, it’s also incrediblycostly <strong>and</strong> impractical. Plus, by the timemost car owners notice a rust spot, a significantamount of iron has already sloughed offof the car, lost to wind <strong>and</strong> rain.One solution to stopping iron’s thermodynamicconversion, says Scully, would be tomake cars out of a metal that doesn’t corrode,such as gold or silver. “Converting toan oxide isn’t thermodynamically favorableMIKE CIESIELSKI18 ChemMatters, FEBRUARY 2006

This student investigates the role of salt on therate of rusting by putting nails in various saltwater solutions.MIKE CIESIELSKIIt’s not only cars that are rusting away. Corrosion costs the United States a whopping$276 billion per year!GETTY IMAGESreaction for these metals, so they won’t corrodespontaneously,” he says. “Archaeologistscan dig up gold coins that have survivedthrough the ages without corroding.”But while driving a gold car might makeyou feel like a million bucks, making such avehicle would cost substantially more. Not tomention the fact that these soft metals wouldbe unable to support the car’s weight <strong>and</strong>would squash like putty in a collision!Even using noncorroding metals that arecheaper than gold or silver, such as stainlesssteel that Deloreans are made of, is still moreexpensive than using the plain steel that mostcars are made of today.The best way to prevent corrosion is stillthe cheapest. A good coating of paintremoves the connection between anode <strong>and</strong>cathode by preventing water from makingcontact with steel. Without water, rustingslows down to a snail’s pace.MIKE CIESIELSKIToday’s high tech paints have evolvedfar from being just a simple barrier, saysScully. Researchers are currently working onpaints that release rust inhibitors on dem<strong>and</strong>when paint’s seal on steel is breached, forexample, when the paint on a car is scrapedor scratched. Other “smart paints” that oozetogether to close gaps whenever a car’s panelsget scratched are also in the works.Although rust is a big deal for car owners,it's an even bigger deal for industries thatrely on machines with metal parts, rangingfrom farm tools to factory equipment tofighter jets. According to Scully, corrosioncosts the United States a whopping annualtoll of about $276 billion in lost goods <strong>and</strong>services. With the exorbitant cost of new militaryequipment, the Department of Defense(DOD) is one of the largest investors inantirust research, says Scully. Scientists atthe DOD hope they can keep the aging Blackhawkhelicopters <strong>and</strong> B52 bombers that arecurrently in use running smoothly fordecades to come—a cost savings of millionsof dollars per machine.But one military asset sometimesharmed by corrosion is extremely difficult toput a price on, says Scully. “If a soldier goesto war <strong>and</strong> the rifle he’s using to protect himselfdoesn't fire when he needs it to, how doyou estimate the cost of corrosion then?”Christen Brownlee is a contributing editor toChemMatters. Her article “Super Fibers” alsoappears in this issue.ChemMatters, FEBRUARY 2006 19

C hem.matters.linksWith a flash of light,nanotubes ignite!Shine light on some materials<strong>and</strong> they will make an audiblesound. This interesting phenomenonis known as a photoacoustic oroptoacoustic effect.The photoacoustic effect wasfirst discovered by Alex<strong>and</strong>er GrahamBell <strong>and</strong> reported to the world in1880. While working on the photophone,he inadvertently discoveredthat if a beam of light was focusedon a selenium cell <strong>and</strong> then rapidlyinterrupted by a rotating disk, the cellproduced an audible sound. He furtherdemonstrated that the strengthof the photoacoustic effect is dependenton the strength of lightabsorbed by the material.Shine light on some newnanoscale materials <strong>and</strong> they’ll notonly sound off, but they actuallyignite under an ordinary cameraflash. Enhanced photothermal propertiesare one of the many unexpectedproperties that researchersare discovering as they delve intothe realm of nanoscale materials.Single-walled carbonnanotubesLast year, researchers atRensselear Polytechnic Institute inTroy, NY, reported in Science thatsingle-walled carbon nanotubes(SWNTs) of a dry, “fluffy” natureignite when exposed to a conventionalflash at close range.Similar materials such as C60,fluffy carbon soot, <strong>and</strong> multiwalledcarbon nanotubes do not ignite.The researchers believe thenanotubes must have an enhancedability to absorb light <strong>and</strong> convertit to heat (a photothermal effect).In the “fluffy” bundles, the heatdoes not dissipate <strong>and</strong> reaches anestimated 1,500°C—more thanenough to ignite the SWNTs. Otherresearchers have hypothesizedthat part of this effect might relyon metal impurities present fromthe manufacture of the SWNTs.See SWNTs ignite <strong>and</strong> burnafter exposure to an ordinary cameraflash.http://www.sciencemag.org/cgi/content/full/296/5568/705/DC1Silicon nanowiresIn an article in Nano Letters,researchers at the University of Science<strong>and</strong> Technology in Hong Konghave described a similar phenomenoninvolving enhanced photothermaleffect in Silicon (Si) nanowires.When these nanowires are hit by alight, they make an audiblepop. If the flash has sufficientpower the Si nanowiresignite. Like SWNTs, theresearchers see evidencethat the Si nanowires experiencetemperatures ofapproximately 1500 °Cduring the flash.The figures on the rightshow Si nanowires before <strong>and</strong>after a flash under an inertatmosphere. The nanowiresdon’t ignite, but they get hotenough to melt Si. Theauthors believe that “the opticalabsorption in Si nanowires wasenhanced by their special structure.”The same effect is notobserved in bulk silicon material,<strong>and</strong> yet the absorption spectrum ofSi nanowires <strong>and</strong> pure Si singlecrystals is similar. The mechanismis unclear, but the Si nanowiresmust clearly “trap an incredibleamount of energy from the flash.”The ignition of the Si nanowires isdistinct from carbon nanotubesbecause there is no metal impurityin Si nanowires.Because of the unexpectedability to confine photoenergy, Sinanowires may find uses in “smartignition systems, self-destructingsystems for electronic devices,nanosensors, <strong>and</strong> nanostructuralor nanophase reformation fornanotechnology.”See Si nanowires resist burningin gas flame, only to ignite aftera flash of light at:http://www.chemistry.org/portal/resources?id=3f136aba6e8711d7f03f6ed9fe800100Tell us what you thinkLet us know about the chemistrythat counts in your life. E-mailyour thoughts <strong>and</strong> suggestionsto chemmatters@acs.org, <strong>and</strong>we’ll use your comment to makefuture issues even better.1155 Sixteenth Street, NWWashington, DC 20036-4800Reach Us on the Web atchemistry.org/education/chemmatters.htmlA publication of the Education Division of the American Chemical Society