Model YLAA Air-Cooled Scroll Compressor Liquid Chillers Style B

Model YLAA Air-Cooled Scroll Compressor Liquid Chillers ... - DCES

Model YLAA Air-Cooled Scroll Compressor Liquid Chillers ... - DCES

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

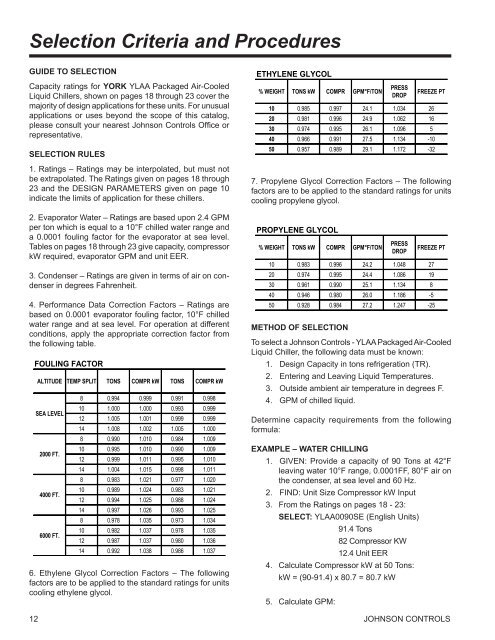

Selection Criteria and ProceduresGUIDE TO SELECTIONCapacity ratings for YORK <strong>YLAA</strong> Packaged <strong>Air</strong>-<strong>Cooled</strong><strong>Liquid</strong> <strong>Chillers</strong>, shown on pages 18 through 23 cover themajority of design applications for these units. For unusualapplications or uses beyond the scope of this catalog,please consult your nearest Johnson Controls Office orrepresentative.SELECTION RULES1. Ratings – Ratings may be interpolated, but must notbe extrapolated. The Ratings given on pages 18 through23 and the DESIGN PARAMETERS given on page 10indicate the limits of application for these chillers.2. Evaporator Water – Ratings are based upon 2.4 GPMper ton which is equal to a 10°F chilled water range anda 0.0001 fouling factor for the evaporator at sea level.Tables on pages 18 through 23 give capacity, compressorkW required, evaporator GPM and unit EER.3. Condenser – Ratings are given in terms of air on condenserin degrees Fahrenheit.4. Performance Data Correction Factors – Ratings arebased on 0.0001 evaporator fouling factor, 10°F chilledwater range and at sea level. For operation at differentconditions, apply the appropriate correction factor fromthe following table.FOULING FACTORALTITUDE TEMP SPLIT TONS COMPR kW TONS COMPR kWSEA LEVEL2000 FT.4000 FT.6000 FT.8 0.994 0.999 0.991 0.99810 1.000 1.000 0.993 0.99912 1.005 1.001 0.999 0.99914 1.008 1.002 1.005 1.0008 0.990 1.010 0.984 1.00910 0.995 1.010 0.990 1.00912 0.999 1.011 0.995 1.01014 1.004 1.015 0.998 1.0118 0.983 1.021 0.977 1.02010 0.989 1.024 0.983 1.02112 0.994 1.025 0.988 1.02414 0.997 1.026 0.993 1.0258 0.978 1.035 0.973 1.03410 0.982 1.037 0.978 1.03512 0.987 1.037 0.980 1.03614 0.992 1.038 0.986 1.0376. Ethylene Glycol Correction Factors – The followingfactors are to be applied to the standard ratings for unitscooling ethylene glycol.ETHYLENE GLYCOLPRESS% WEIGHT TONS kW COMPR GPM°F/TON FREEZE PTDROP10 0.985 0.997 24.1 1.034 2620 0.981 0.996 24.9 1.062 1630 0.974 0.995 26.1 1.096 540 0.966 0.991 27.5 1.134 -1050 0.957 0.989 29.1 1.172 -327. Propylene Glycol Correction Factors – The followingfactors are to be applied to the standard ratings for unitscooling propylene glycol.PROPYLENE GLYCOLPRESS% WEIGHT TONS kW COMPR GPM°F/TON FREEZE PTDROP10 0.983 0.996 24.2 1.048 2720 0.974 0.995 24.4 1.086 1930 0.961 0.990 25.1 1.134 840 0.946 0.980 26.0 1.186 -550 0.928 0.984 27.2 1.247 -25METHOD OF SELECTIONTo select a Johnson Controls - <strong>YLAA</strong> Packaged <strong>Air</strong>-<strong>Cooled</strong><strong>Liquid</strong> Chiller, the following data must be known:1. Design Capacity in tons refrigeration (TR).2. Entering and Leaving <strong>Liquid</strong> Temperatures.3. Outside ambient air temperature in degrees F.4. GPM of chilled liquid.Determine capacity requirements from the followingformula:EXAMPLE – WATER CHILLING1. GIVEN: Provide a capacity of 90 Tons at 42°Fleaving water 10°F range, 0.0001FF, 80°F air onthe condenser, at sea level and 60 Hz.2. FIND: Unit Size <strong>Compressor</strong> kW Input3. From the Ratings on pages 18 - 23:SELECT: <strong>YLAA</strong>0090SE (English Units)91.4 Tons82 <strong>Compressor</strong> KW12.4 Unit EER4. Calculate <strong>Compressor</strong> kW at 50 Tons:kW = (90-91.4) x 80.7 = 80.7 kW5. Calculate GPM:12 jOHNSON CONTROLS