BUTTERWORTH

BUTTERWORTH - Sintemar

BUTTERWORTH - Sintemar

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

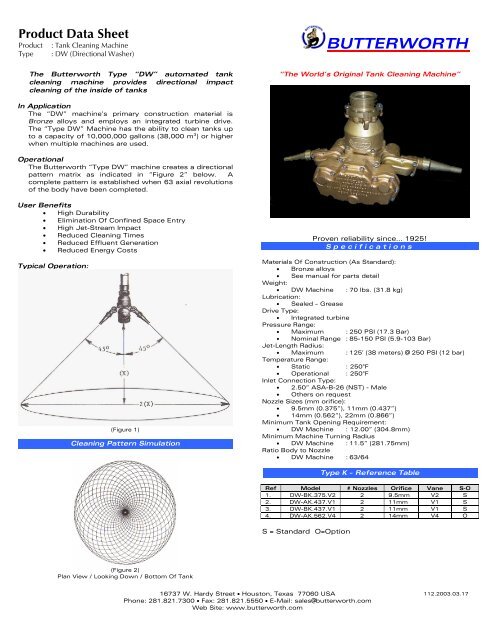

Product Data SheetProductType: Tank Cleaning Machine: DW (Directional Washer)<strong>BUTTERWORTH</strong>The Butterworth Type “DW” automated tankcleaning machine provides directional impactcleaning of the inside of tanks“The World’s Original Tank Cleaning Machine”In ApplicationThe “DW” machine’s primary construction material isBronze alloys and employs an integrated turbine drive.The “Type DW” Machine has the ability to clean tanks upto a capacity of 10,000,000 gallons (38,000 m 3 ) or higherwhen multiple machines are used.OperationalThe Butterworth “Type DW” machine creates a directionalpattern matrix as indicated in “Figure 2” below. Acomplete pattern is established when 63 axial revolutionsof the body have been completed.User Benefits• High Durability• Elimination Of Confined Space Entry• High Jet-Stream Impact• Reduced Cleaning Times• Reduced Effluent Generation• Reduced Energy CostsTypical Operation:(Figure 1)Cleaning Pattern SimulationProven reliability since… 1925!SpecificationsMaterials Of Construction (As Standard):• Bronze alloys• See manual for parts detailWeight:• DW Machine : 70 lbs. (31.8 kg)Lubrication:• Sealed – GreaseDrive Type:• Integrated turbinePressure Range:• Maximum : 250 PSI (17.3 Bar)• Nominal Range : 85-150 PSI (5.9-103 Bar)Jet-Length Radius:• Maximum : 125’ (38 meters) @ 250 PSI (12 bar)Temperature Range:• Static : 250°F• Operational : 250°FInlet Connection Type:• 2.50” ASA-B-26 (NST) - Male• Others on requestNozzle Sizes (mm orifice):• 9.5mm (0.375”), 11mm (0.437”)• 14mm (0.562”), 22mm (0.866”)Minimum Tank Opening Requirement:• DW Machine : 12.00” (304.8mm)Minimum Machine Turning Radius• DW Machine : 11.5” (281.75mm)Ratio Body to Nozzle• DW Machine : 63/64Type K – Reference TableRef Model # Nozzles Orifice Vane S-O1. DW-BK.375.V2 2 9.5mm V2 S2. DW-AK.437.V1 2 11mm V1 S3. DW-BK.437.V1 2 11mm V1 S4. DW-AK.562.V4 2 14mm V4 OS = Standard O=Option(Figure 2)Plan View / Looking Down / Bottom Of Tank16737 W. Hardy Street • Houston, Texas 77060 USAPhone: 281.821.7300 • Fax: 281.821.5550 • E-Mail: sales@butterworth.comWeb Site: www.butterworth.com112.2003.03.17

Product Data SheetProductType: Tank Cleaning Machine: DW (Directional Washer)<strong>BUTTERWORTH</strong>Flow/PressureUSGPM500Cubic Meters Per Hour114Cleaning Pattern Time (Additional pattern times are available)Minutes70480109686646010464440100624209560584003803602 x 22mm (0.866)9186825654525034077483207346443002802602 x 14mm (0.562)68645942403836240553422050323020045282 x 9.5mm (0.375 - V1)2 x 22mm (0.866 - V4)1801601402 x 11mm (0.437)413632262422202 x 11mm (0.437 - V1)1201002 x 9.5mm (0.375)27231816142 x 14mm (0.562- V4)80601814121084096205420000 20 40 60 80 100 120 140 160 180 200 220 24040 60 80 100 120 140 160 180 200 220 240Pressure in PSIPressure in PSIMaximum Jet Throw LengthFeet135Meters49Impact Pressure @ 100 PSIGPounds/Square Foot1501304746140125441201151101051009590Maximum Throw Length2 x 22mm (0.866)2 x 14mm (0.562)2 x 11mm (0.437)2 x 9.5mm (0.375)43414038373534323029271301201101009085807570Throw Length >= 50#/ft 22 x 22mm (0.866)2 x 14mm (0.562)2 x 11mm (0.437)2 x 9.5mm (0.375)2624232120188070602 x 22mm (0.866)651715502 x 14mm (0.562)605550141211940302 x 11mm (0.437)2 x 9.5mm (0.375)4586204053532103000 20 40 60 80 100 120 140 160 180 200 220 240Pressure in PSIImportant Notice:The curves presented here are summary in nature. For acomplete set of curves, contact Butterworth.00 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85Distance From Center of Machine - Related in FeetContact Butterworth for installation and engineering assistance.16737 W. Hardy Street • Houston, Texas 77060 USAPhone: 281.821.7300 • Fax: 281.821.5550 • E-Mail: sales@butterworth.comWeb Site: www.butterworth.com112.2003.03.17