CHOCKFAST Orange Hardener Ratio Guide for Chocking Between Steel & Concrete

665B CF Orange Hardener Ratio Guide Concrete - Sintemar

665B CF Orange Hardener Ratio Guide Concrete - Sintemar

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

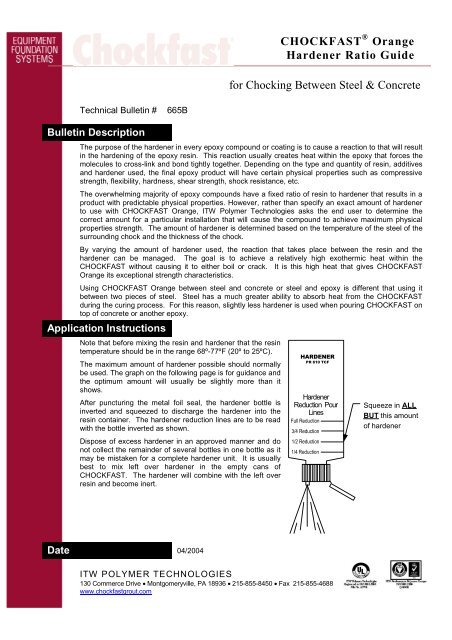

<strong>CHOCKFAST</strong> ® <strong>Orange</strong><strong>Hardener</strong> <strong>Ratio</strong> <strong>Guide</strong><strong>for</strong> <strong>Chocking</strong> <strong>Between</strong> <strong>Steel</strong> & <strong>Concrete</strong>Technical Bulletin #665BBulletin DescriptionThe purpose of the hardener in every epoxy compound or coating is to cause a reaction to that will resultin the hardening of the epoxy resin. This reaction usually creates heat within the epoxy that <strong>for</strong>ces themolecules to cross-link and bond tightly together. Depending on the type and quantity of resin, additivesand hardener used, the final epoxy product will have certain physical properties such as compressivestrength, flexibility, hardness, shear strength, shock resistance, etc.The overwhelming majority of epoxy compounds have a fixed ratio of resin to hardener that results in aproduct with predictable physical properties. However, rather than specify an exact amount of hardenerto use with <strong>CHOCKFAST</strong> <strong>Orange</strong>, ITW Polymer Technologies asks the end user to determine thecorrect amount <strong>for</strong> a particular installation that will cause the compound to achieve maximum physicalproperties strength. The amount of hardener is determined based on the temperature of the steel of thesurrounding chock and the thickness of the chock.By varying the amount of hardener used, the reaction that takes place between the resin and thehardener can be managed. The goal is to achieve a relatively high exothermic heat within the<strong>CHOCKFAST</strong> without causing it to either boil or crack. It is this high heat that gives <strong>CHOCKFAST</strong><strong>Orange</strong> its exceptional strength characteristics.Using <strong>CHOCKFAST</strong> <strong>Orange</strong> between steel and concrete or steel and epoxy is different that using itbetween two pieces of steel. <strong>Steel</strong> has a much greater ability to absorb heat from the <strong>CHOCKFAST</strong>during the curing process. For this reason, slightly less hardener is used when pouring <strong>CHOCKFAST</strong> ontop of concrete or another epoxy.Application InstructionsNote that be<strong>for</strong>e mixing the resin and hardener that the resintemperature should be in the range 68º-77ºF (20º to 25ºC).The maximum amount of hardener possible should normallybe used. The graph on the following page is <strong>for</strong> guidance andthe optimum amount will usually be slightly more than itshows.After puncturing the metal foil seal, the hardener bottle isinverted and squeezed to discharge the hardener into theresin container. The hardener reduction lines are to be readwith the bottle inverted as shown.Dispose of excess hardener in an approved manner and donot collect the remainder of several bottles in one bottle as itmay be mistaken <strong>for</strong> a complete hardener unit. It is usuallybest to mix left over hardener in the empty cans of<strong>CHOCKFAST</strong>. The hardener will combine with the left overresin and become inert.HARDENERPR 610 TCF<strong>Hardener</strong>Reduction PourLinesFull Reduction3/4 Reduction1/2 Reduction1/4 ReductionSqueeze in ALLBUT this amountof hardenerDate 04/2004ITW POLYMER TECHNOLOGIES130 Commerce Drive Montgomeryville, PA 18936 215-855-8450 Fax 215-855-4688www.chockfastgrout.com

<strong>CHOCKFAST</strong> <strong>Orange</strong> <strong>Hardener</strong> <strong>Ratio</strong> <strong>Guide</strong>Bulletin No. 665B, Page 2<strong>Steel</strong> Temperature, o F10040 50 60 68 77 86 95 104 1134Chock Thickness, mm80604020APPLY HEAT AFTERRESIN HARDENSFULL HARDENER REDUCTION3/4 REDUCTION1/2 REDUCTION1/4 REDUCTIONNO HARDENER REDUCTIONLAYERED POURS33222119163/43/8183438916316Chock Thickness, inches5 10 15 20 25 30 35 40 45<strong>Steel</strong> Temperature, o C<strong>Steel</strong> Temperature, o F10040 50 60 68 77 86 95 104 1134Example:40 mm (1-9/16”) chockswith a steel temperatureof 27 o C (80 o F) requiresa ¾ <strong>Hardener</strong> ReductionChock Thickness, mm80604020APPLY HEAT AFTERRESIN HARDENSFULL HARDENER REDUCTION3/4 REDUCTION1/2 REDUCTION1/4 REDUCTIONNO HARDENER REDUCTIONLAYERED POURS5 10 15 20 25 30 35 40 4533222119163/43/8183438916316Chock Thickness, inches<strong>Steel</strong> Temperature, o CGeneral: Every reasonable ef<strong>for</strong>t is made to insure thetechnical in<strong>for</strong>mation and recommendations on these datapages are true and accurate to the best of our knowledgeat the date of issuance. However, this in<strong>for</strong>mation is subjectto change without notice. Prior versions of this publicationare invalid with the release of this version. Products andin<strong>for</strong>mation are intended <strong>for</strong> use by qualified applicatorsthat have the required background, technical knowledge,and equipment to per<strong>for</strong>m said tasks in a satisfactorymanner. Consult your local distributor <strong>for</strong> productavailability, additional product in<strong>for</strong>mation, and technicalsupport.Warranty: ITW Polymer Technologies, a division of Illinois ToolWorks Inc., warrants that its products meet their printedspecifications. This is the sole warranty. This warrantyexpires one year after product shipment.Warranty Claims: If any product fails to meet the above,ITW Polymer Technologies will, at its option, either replacethe product or refund the purchase price. ITW PolymerTechnologies will have no other liability <strong>for</strong> breach ofwarranty, negligence, or otherwise. All warranty claimsmust be made in writing within one year of the date ofshipment. No other claims will be considered.Disclaimer: ITW Polymer Technologies makes no otherwarranty, expressed or implied, and specifically disclaimsany warranty of merchantability or fitness <strong>for</strong> a particularpurpose.Suggestions concerning the use of products are notwarranties. The purchaser assumes the responsibility <strong>for</strong>determining suitability of products and appropriate use.ITW Polymer Technologies’ sole liability, <strong>for</strong> breach ofwarranty, negligence or otherwise, shall be thereplacement of product or refund of the purchaseprice, at ITW Polymer Technologies’ election. Under nocircumstances shall ITW Polymer Technologies be liable<strong>for</strong> any indirect, incidental or consequential damages.Modification of Warranty: No distributor or salesrepresentative has the authority to change the aboveprovisions. No change in the above provisions will bevalid unless in writing and signed by an officer or theTechnical Director of ITW Polymer Technologies. Noterm of any purchase order shall serve to modify anyprovision of this document.Mediation and Arbitration: If any dispute arises relatingto products or product warranties, either the purchaseror ITW Polymer Technologies may a) initiate mediationunder the then current Center <strong>for</strong> Public Resources(CPR) Model Procedure <strong>for</strong> Mediation of BusinessDisputes, or b) initiate a non-binding arbitration underthe rules of the American Arbitration Association <strong>for</strong> theresolution of commercial disputes.