CHOCKFAST Red – Liquids ONLY

CHOCKFAST Red â Liquids ONLY - Sintemar

CHOCKFAST Red â Liquids ONLY - Sintemar

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

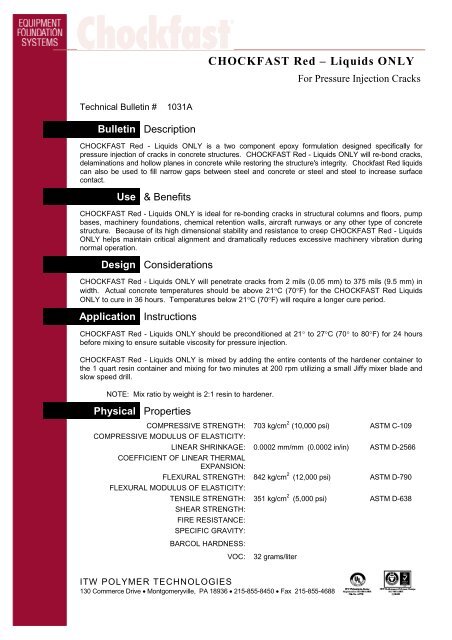

<strong>CHOCKFAST</strong> <strong>Red</strong> <strong>–</strong> <strong>Liquids</strong> <strong>ONLY</strong>For Pressure Injection CracksTechnical Bulletin #1031ABulletin Description<strong>CHOCKFAST</strong> <strong>Red</strong> - <strong>Liquids</strong> <strong>ONLY</strong> is a two component epoxy formulation designed specifically forpressure injection of cracks in concrete structures. <strong>CHOCKFAST</strong> <strong>Red</strong> - <strong>Liquids</strong> <strong>ONLY</strong> will re-bond cracks,delaminations and hollow planes in concrete while restoring the structure's integrity. Chockfast <strong>Red</strong> liquidscan also be used to fill narrow gaps between steel and concrete or steel and steel to increase surfacecontact.Use & Benefits<strong>CHOCKFAST</strong> <strong>Red</strong> - <strong>Liquids</strong> <strong>ONLY</strong> is ideal for re-bonding cracks in structural columns and floors, pumpbases, machinery foundations, chemical retention walls, aircraft runways or any other type of concretestructure. Because of its high dimensional stability and resistance to creep <strong>CHOCKFAST</strong> <strong>Red</strong> - <strong>Liquids</strong><strong>ONLY</strong> helps maintain critical alignment and dramatically reduces excessive machinery vibration duringnormal operation.Design Considerations<strong>CHOCKFAST</strong> <strong>Red</strong> - <strong>Liquids</strong> <strong>ONLY</strong> will penetrate cracks from 2 mils (0.05 mm) to 375 mils (9.5 mm) inwidth. Actual concrete temperatures should be above 21C (70F) for the <strong>CHOCKFAST</strong> <strong>Red</strong> <strong>Liquids</strong><strong>ONLY</strong> to cure in 36 hours. Temperatures below 21C (70F) will require a longer cure period.Application Instructions<strong>CHOCKFAST</strong> <strong>Red</strong> - <strong>Liquids</strong> <strong>ONLY</strong> should be preconditioned at 21 to 27C (70 to 80F) for 24 hoursbefore mixing to ensure suitable viscosity for pressure injection.<strong>CHOCKFAST</strong> <strong>Red</strong> - <strong>Liquids</strong> <strong>ONLY</strong> is mixed by adding the entire contents of the hardener container tothe 1 quart resin container and mixing for two minutes at 200 rpm utilizing a small Jiffy mixer blade andslow speed drill.NOTE: Mix ratio by weight is 2:1 resin to hardener.Physical PropertiesCOMPRESSIVE STRENGTH: 703 kg/cm 2 (10,000 psi) ASTM C-109COMPRESSIVE MODULUS OF ELASTICITY:LINEAR SHRINKAGE: 0.0002 mm/mm (0.0002 in/in) ASTM D-2566COEFFICIENT OF LINEAR THERMALEXPANSION:FLEXURAL STRENGTH: 842 kg/cm 2 (12,000 psi) ASTM D-790FLEXURAL MODULUS OF ELASTICITY:TENSILE STRENGTH: 351 kg/cm 2 (5,000 psi) ASTM D-638SHEAR STRENGTH:FIRE RESISTANCE:SPECIFIC GRAVITY:BARCOL HARDNESS:VOC:32 grams/literITW POLYMER TECHNOLOGIES130 Commerce Drive Montgomeryville, PA 18936 215-855-8450 Fax 215-855-4688