PRODUCT CATALOG

PRODUCT CATALOG - Precise Automation

PRODUCT CATALOG - Precise Automation

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

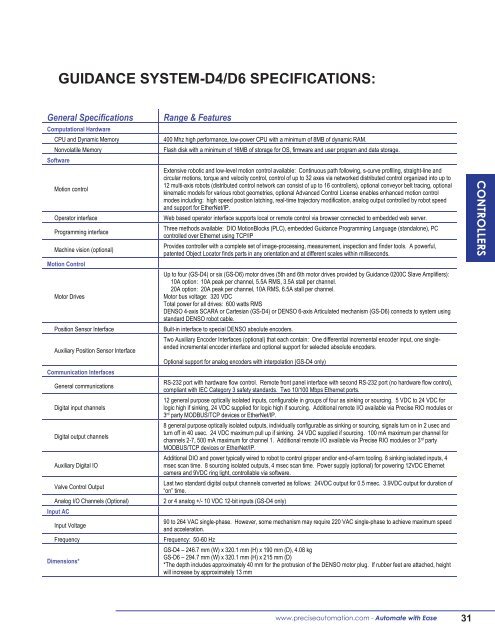

GUIDANCE SYSTEM-D4/D6 SPECIFICATIONS:<br />

General Specifications<br />

Computational Hardware<br />

CPU and Dynamic Memory<br />

Nonvolatile Memory<br />

Software<br />

Motion control<br />

Operator interface<br />

Programming interface<br />

Machine vision (optional)<br />

Motion Control<br />

Motor Drives<br />

Position Sensor Interface<br />

Auxiliary Position Sensor Interface<br />

Communication Interfaces<br />

General communications<br />

Digital input channels<br />

Digital output channels<br />

Auxiliary Digital IO<br />

Valve Control Output<br />

Analog I/O Channels (Optional)<br />

Input AC<br />

Input Voltage<br />

Frequency<br />

Dimensions*<br />

Range & Features<br />

400 Mhz high performance, low-power CPU with a minimum of 8MB of dynamic RAM.<br />

Flash disk with a minimum of 16MB of storage for OS, firmware and user program and data storage.<br />

Extensive robotic and low-level motion control available: Continuous path following, s-curve profiling, straight-line and<br />

circular motions, torque and velocity control, control of up to 32 axes via networked distributed control organized into up to<br />

12 multi-axis robots (distributed control network can consist of up to 16 controllers), optional conveyor belt tracing, optional<br />

kinematic models for various robot geometries, optional Advanced Control License enables enhanced motion control<br />

modes including: high speed position latching, real-time trajectory modification, analog output controlled by robot speed<br />

and support for EtherNet/IP.<br />

Web based operator interface supports local or remote control via browser connected to embedded web server.<br />

Three methods available: DIO MotionBlocks (PLC), embedded Guidance Programming Language (standalone), PC<br />

controlled over Ethernet using TCP/IP<br />

Provides controller with a complete set of image-processing, measurement, inspection and finder tools. A powerful,<br />

patented Object Locator finds parts in any orientation and at different scales within milliseconds.<br />

Up to four (GS-D4) or six (GS-D6) motor drives (5th and 6th motor drives provided by Guidance 0200C Slave Amplifiers):<br />

10A option: 10A peak per channel, 5.5A RMS, 3.5A stall per channel.<br />

20A option: 20A peak per channel, 10A RMS, 6.5A stall per channel.<br />

Motor bus voltage: 320 VDC<br />

Total power for all drives: 600 watts RMS<br />

DENSO 4-axis SCARA or Cartesian (GS-D4) or DENSO 6-axis Articulated mechanism (GS-D6) connects to system using<br />

standard DENSO robot cable.<br />

Built-in interface to special DENSO absolute encoders.<br />

Two Auxiliary Encoder Interfaces (optional) that each contain: One differential incremental encoder input, one singleended<br />

incremental encoder interface and optional support for selected absolute encoders.<br />

Optional support for analog encoders with interpolation (GS-D4 only)<br />

RS-232 port with hardware flow control. Remote front panel interface with second RS-232 port (no hardware flow control),<br />

compliant with IEC Category 3 safety standards. Two 10/100 Mbps Ethernet ports.<br />

12 general purpose optically isolated inputs, configurable in groups of four as sinking or sourcing. 5 VDC to 24 VDC for<br />

logic high if sinking, 24 VDC supplied for logic high if sourcing. Additional remote I/O available via Precise RIO modules or<br />

3 rd party MODBUS/TCP devices or EtherNet/IP.<br />

8 general purpose optically isolated outputs, individually configurable as sinking or sourcing, signals turn on in 2 usec and<br />

turn off in 40 usec. 24 VDC maximum pull up if sinking. 24 VDC supplied if sourcing. 100 mA maximum per channel for<br />

channels 2-7, 500 mA maximum for channel 1. Additional remote I/O available via Precise RIO modules or 3 rd party<br />

MODBUS/TCP devices or EtherNet/IP.<br />

Additional DIO and power typically wired to robot to control gripper and/or end-of-arm tooling. 8 sinking isolated inputs, 4<br />

msec scan time. 8 sourcing isolated outputs, 4 msec scan time. Power supply (optional) for powering 12VDC Ethernet<br />

camera and 9VDC ring light, controllable via software.<br />

Last two standard digital output channels converted as follows: 24VDC output for 0.5 msec. 3.9VDC output for duration of<br />

“on” time.<br />

2 or 4 analog +/- 10 VDC 12-bit inputs (GS-D4 only)<br />

90 to 264 VAC single-phase. However, some mechanism may require 220 VAC single-phase to achieve maximum speed<br />

and acceleration.<br />

Frequency: 50-60 Hz<br />

GS-D4 – 246.7 mm (W) x 320.1 mm (H) x 190 mm (D), 4.08 kg<br />

GS-D6 – 294.7 mm (W) x 320.1 mm (H) x 215 mm (D)<br />

*The depth includes approximately 40 mm for the protrusion of the DENSO motor plug. If rubber feet are attached, height<br />

will increase by approximately 13 mm<br />

CONTROLLERS<br />

www.preciseautomation.com - Automate with Ease 31