MARITIME

download

download

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

EYE ON DESIGN<br />

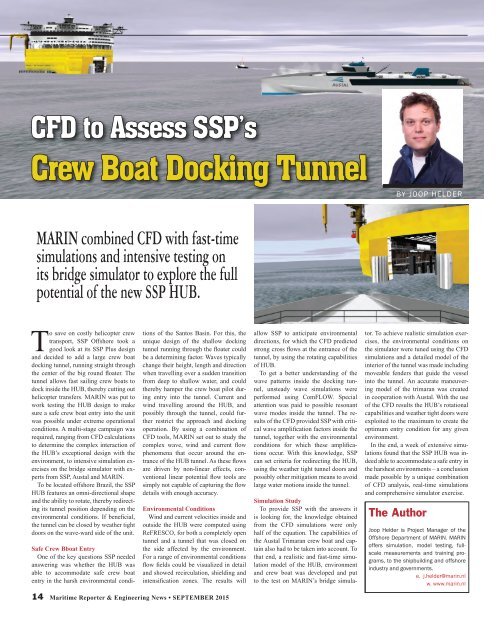

CFD to Assess SSP’s<br />

Crew Boat Docking Tunnel<br />

BY JOOP HELDER<br />

MARIN combined CFD with fast-time<br />

simulations and intensive testing on<br />

its bridge simulator to explore the full<br />

potential of the new SSP HUB.<br />

To save on costly helicopter crew<br />

transport, SSP Offshore took a<br />

good look at its SSP Plus design<br />

and decided to add a large crew boat<br />

docking tunnel, running straight through<br />

the center of the big round floater. The<br />

tunnel allows fast sailing crew boats to<br />

dock inside the HUB, thereby cutting out<br />

helicopter transfers. MARIN was put to<br />

work testing the HUB design to make<br />

sure a safe crew boat entry into the unit<br />

was possible under extreme operational<br />

conditions. A multi-stage campaign was<br />

required, ranging from CFD calculations<br />

to determine the complex interaction of<br />

the HUB’s exceptional design with the<br />

environment, to intensive simulation exercises<br />

on the bridge simulator with experts<br />

from SSP, Austal and MARIN.<br />

To be located offshore Brazil, the SSP<br />

HUB features an omni-directional shape<br />

and the ability to rotate, thereby redirecting<br />

its tunnel position depending on the<br />

environmental conditions. If beneficial,<br />

the tunnel can be closed by weather tight<br />

doors on the wave-ward side of the unit.<br />

Safe Crew Bboat Entry<br />

One of the key questions SSP needed<br />

answering was whether the HUB was<br />

able to accommodate safe crew boat<br />

entry in the harsh environmental conditions<br />

of the Santos Basin. For this, the<br />

unique design of the shallow docking<br />

tunnel running through the floater could<br />

be a determining factor. Waves typically<br />

change their height, length and direction<br />

when travelling over a sudden transition<br />

from deep to shallow water, and could<br />

thereby hamper the crew boat pilot during<br />

entry into the tunnel. Current and<br />

wind travelling around the HUB, and<br />

possibly through the tunnel, could further<br />

restrict the approach and docking<br />

operation. By using a combination of<br />

CFD tools, MARIN set out to study the<br />

complex wave, wind and current flow<br />

phenomena that occur around the entrance<br />

of the HUB tunnel. As these flows<br />

are driven by non-linear effects, conventional<br />

linear potential flow tools are<br />

simply not capable of capturing the flow<br />

details with enough accuracy.<br />

Environmental Conditions<br />

Wind and current velocities inside and<br />

outside the HUB were computed using<br />

ReFRESCO, for both a completely open<br />

tunnel and a tunnel that was closed on<br />

the side affected by the environment.<br />

For a range of environmental conditions<br />

flow fields could be visualized in detail<br />

and showed recirculation, shielding and<br />

intensification zones. The results will<br />

allow SSP to anticipate environmental<br />

directions, for which the CFD predicted<br />

strong cross flows at the entrance of the<br />

tunnel, by using the rotating capabilities<br />

of HUB.<br />

To get a better understanding of the<br />

wave patterns inside the docking tunnel,<br />

unsteady wave simulations were<br />

performed using ComFLOW. Special<br />

attention was paid to possible resonant<br />

wave modes inside the tunnel. The results<br />

of the CFD provided SSP with critical<br />

wave amplification factors inside the<br />

tunnel, together with the environmental<br />

conditions for which these amplifications<br />

occur. With this knowledge, SSP<br />

can set criteria for redirecting the HUB,<br />

using the weather tight tunnel doors and<br />

possibly other mitigation means to avoid<br />

large water motions inside the tunnel.<br />

Simulation Study<br />

To provide SSP with the answers it<br />

is looking for, the knowledge obtained<br />

from the CFD simulations were only<br />

half of the equation. The capabilities of<br />

the Austal Trimaran crew boat and captain<br />

also had to be taken into account. To<br />

that end, a realistic and fast-time simulation<br />

model of the HUB, environment<br />

and crew boat was developed and put<br />

to the test on MARIN’s bridge simulator.<br />

To achieve realistic simulation exercises,<br />

the environmental conditions on<br />

the simulator were tuned using the CFD<br />

simulations and a detailed model of the<br />

interior of the tunnel was made including<br />

moveable fenders that guide the vessel<br />

into the tunnel. An accurate maneuvering<br />

model of the trimaran was created<br />

in cooperation with Austal. With the use<br />

of the CFD results the HUB’s rotational<br />

capabilities and weather tight doors were<br />

exploited to the maximum to create the<br />

optimum entry condition for any given<br />

environment.<br />

In the end, a week of extensive simulations<br />

found that the SSP HUB was indeed<br />

able to accommodate a safe entry in<br />

the harshest environments – a conclusion<br />

made possible by a unique combination<br />

of CFD analysis, real-time simulations<br />

and comprehensive simulator exercise.<br />

The Author<br />

Joop Helder is Project Manager of the<br />

Offshore Department of MARIN. MARIN<br />

offers simulation, model testing, fullscale<br />

measurements and training programs,<br />

to the shipbuilding and offshore<br />

industry and governments.<br />

e. j.helder@marin.nl<br />

w. www.marin.nl<br />

14 Maritime Reporter & Engineering News • SEPTEMBER 2015