SMALL DAMS

SMALL DAMS - Comité Français des Barrages et Réservoirs

SMALL DAMS - Comité Français des Barrages et Réservoirs

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Chapter IV<br />

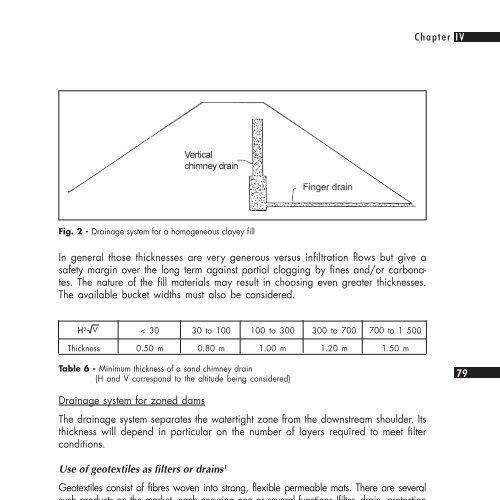

Fig. 2 - Drainage system for a homogeneous clayey fill<br />

In general those thicknesses are very generous versus infiltration flows but give a<br />

safety margin over the long term against partial clogging by fines and/or carbonates.<br />

The nature of the fill materials may result in choosing even greater thicknesses.<br />

The available bucket widths must also be considered.<br />

H² V < 30 30 to 100 100 to 300 300 to 700 700 to 1 500<br />

Thickness 0.50 m 0.80 m 1.00 m 1.20 m 1.50 m<br />

Table 6 - Minimum thickness of a sand chimney drain<br />

(H and V correspond to the altitude being considered)<br />

79<br />

Drainage system for zoned dams<br />

The drainage system separates the watertight zone from the downstream shoulder. Its<br />

thickness will depend in particular on the number of layers required to meet filter<br />

conditions.<br />

Use of geotextiles as filters or drains 1<br />

Geotextiles consist of fibres woven into strong, flexible permeable mats. There are several<br />

such products on the market, each ensuring one or several functions (filter, drain, protection<br />

from puncturing, etc.). Some applications have already been mentioned.<br />

Of course, it is essential to avoid considering a geotextile as a general-purpose product (a<br />

geotextile that can support rockfill placement without tearing is not at all similar to a geotextile<br />

used as a filter).<br />

In a dam, geotextiles are most often used to help in discharging percolation flows by acting<br />

as a protective filter for a granular drainage material (see photo 9 p. IV). However, installation<br />

of a geotextile to protect a chimney drain is no easy matter. In this case, an alternative<br />

solution consists in building the fill dam in two stages, in order to place the geotextile<br />

surrounding the drain on a sloped face that is stable in the short term (see figure 3).<br />

1. See Bibliography, references 3 and 4, p.111.