Cirrus Aircraft Update Webinar

SR22T - Cirrus Design Authorized Service Center Home

SR22T - Cirrus Design Authorized Service Center Home

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

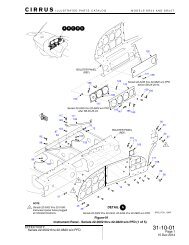

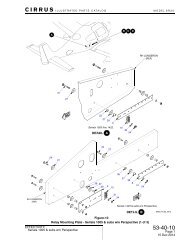

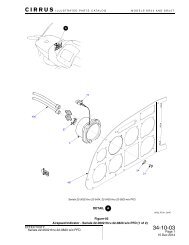

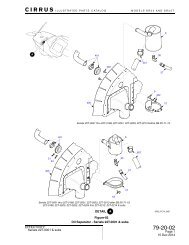

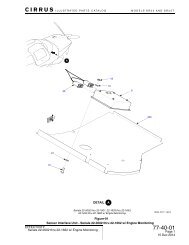

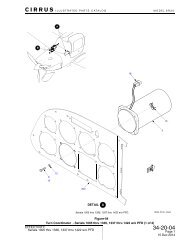

Power plant<br />

SR22T<br />

Inspection/Check - Exhaust System<br />

Visually inspect slip joints for bulges, cracks, or hot spots.<br />

Visually inspect stacks, risers, and elbows for burned areas, cracks, and loose parts or<br />

hardware. Check welded areas and seams for cracks. Replace parts that are cracked,<br />

burned, or worn.<br />

Visually inspect heat exchanger seams, joints and transitions with a flashlight and mirror<br />

or a flexible borescope for physical damage, cracks, corrosion, and burn-through. Inspect<br />

connecting flanges for security and proper mating.<br />

Perform exhaust leak test.<br />

1 Connect a high volume, dust-free, air pressure source to the exhaust tailpipe outlet.<br />

2 Apply 5 psi of air pressure to the exhaust system.<br />

3 Apply soapy water to the exhaust system and check for bubbling. If bubbling is<br />

found, replace the leaking exhaust components.<br />

Visually inspect exhaust stacks and transition unit for wear, leaks, cracks, or distortion.<br />

Replace worn, leaking, cracked, or distorted exhaust parts.<br />

Visually inspect exhaust manifold connections at cylinder for security of exhaust flange,<br />

gasket, and exhaust manifold fasteners.<br />

Visually inspect V-band clamps.<br />

1 Remove V-band clamp from exhaust tailpipe.<br />

2 Clean outer band of V-band clamp with crocus cloth.<br />

3 Inspect V-band clamp spot-weld (or rivet) areas for cracks and looseness.<br />

4 Using a flashlight and mirror, inspect corner radii of clamp inner segments for<br />

cracks. Inspect inner segment spacing.<br />

5 Inspect clamp outer band for flatness using a straight edge, especially within 2<br />

inches of spot-weld tabs that retain the T-bolt fastener. Verify clearance between<br />

clamp outer band and straight edge is less than 0.062 inches (1.57 mm).<br />

6 Verify 100% contact between inner segments and outer band.