Cirrus Aircraft Update Webinar

SR22T - Cirrus Design Authorized Service Center Home

SR22T - Cirrus Design Authorized Service Center Home

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

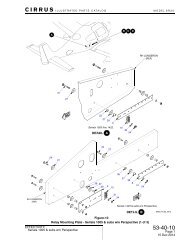

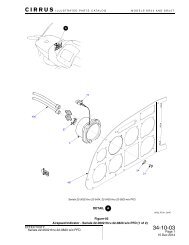

Operational Inspection (SID97-3E)<br />

• 22T-0001 & subs: Functional Inspection of Fuel Injection<br />

System in accordance with the manufacturer’s approved<br />

Instructions For Continued Airworthiness after engine<br />

installation,<br />

every 100 hours, at annual, or fuel system component<br />

replacement. Fuel Pump setup should be performed<br />

as follows:<br />

• At 600 RPM set un-metered pressure to 7.0 - 9.0 psi.<br />

.At 600 RPM, set idle cutoff RPM rise to 30-50 RPM.<br />

• At 2500 RPM and Boost Pump set to BOOST, reference the<br />

MFD gages and set Manifold Pressure and Fuel Flow per the<br />

following graph. Set un-metered pressure to 20.5 - 23.5 psi.<br />

SR22T<br />

Using Portatest unit;<br />

Connect the<br />

unmetered Portatest<br />

hoses to the throttle<br />

metering valve as you<br />

would for a non-turbo<br />

SR22 (you will need -<br />

6 adapters as the<br />

fuels lines are 3/8” on<br />

the SR22T).<br />

Using 0-60 psi gauge;<br />

Disconnect the<br />

unmetered (-6) fuel line<br />

to the throttle metering<br />

valve and insert the -6<br />

swivel run tee. Connect<br />

the tee leg to the<br />

unmetered 0-60 PSI<br />

gauge