THE KIRCHHOFF GROUP MAGAZINE

k-mobil_46_english

k-mobil_46_english

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>KIRCHHOFF</strong> Automotive // 46<br />

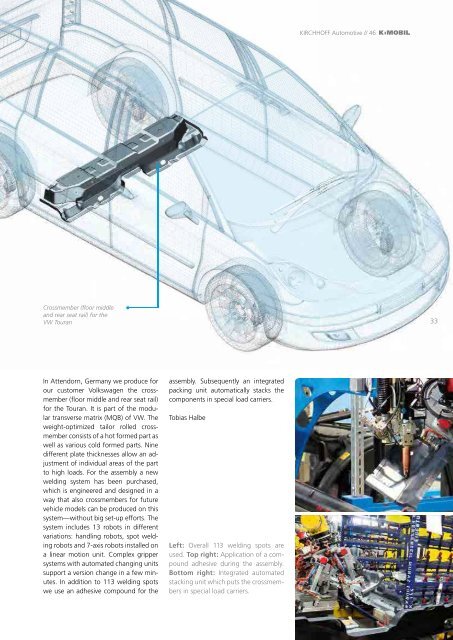

Crossmember (floor middle<br />

and rear seat rail) for the<br />

VW Touran 33<br />

In Attendorn, Germany we produce for<br />

our customer Volkswagen the crossmember<br />

(floor middle and rear seat rail)<br />

for the Touran. It is part of the modular<br />

transverse matrix (MQB) of VW. The<br />

weight-optimized tailor rolled crossmember<br />

consists of a hot formed part as<br />

well as various cold formed parts. Nine<br />

different plate thicknesses allow an adjustment<br />

of individual areas of the part<br />

to high loads. For the assembly a new<br />

welding system has been purchased,<br />

which is engineered and designed in a<br />

way that also crossmembers for future<br />

vehicle models can be produced on this<br />

system—without big set-up efforts. The<br />

system includes 13 robots in different<br />

variations: handling robots, spot welding<br />

robots and 7-axis robots installed on<br />

a linear motion unit. Complex gripper<br />

systems with automated changing units<br />

support a version change in a few minutes.<br />

In addition to 113 welding spots<br />

we use an adhesive compound for the<br />

assembly. Subsequently an integrated<br />

packing unit automatically stacks the<br />

components in special load carriers.<br />

Tobias Halbe<br />

Left: Overall 113 welding spots are<br />

used. Top right: Application of a compound<br />

adhesive during the assembly.<br />

Bottom right: Integrated automated<br />

stacking unit which puts the crossmembers<br />

in special load carriers.