THE KIRCHHOFF GROUP MAGAZINE

k-mobil_46_english

k-mobil_46_english

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

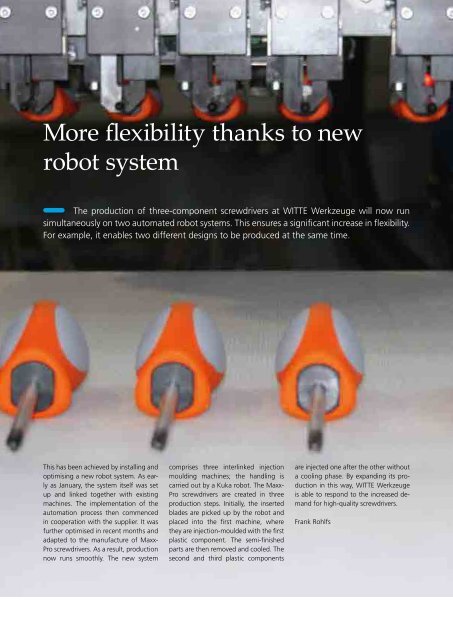

More flexibility thanks to new<br />

robot system<br />

The production of three-component screwdrivers at WITTE Werkzeuge will now run<br />

simultaneously on two automated robot systems. This ensures a significant increase in flexibility.<br />

For example, it enables two different designs to be produced at the same time.<br />

This has been achieved by installing and<br />

optimising a new robot system. As early<br />

as January, the system itself was set<br />

up and linked together with existing<br />

machines. The implementation of the<br />

automation process then commenced<br />

in cooperation with the supplier. It was<br />

further optimised in recent months and<br />

adapted to the manufacture of Maxx-<br />

Pro screwdrivers. As a result, production<br />

now runs smoothly. The new system<br />

comprises three interlinked injection<br />

moulding machines; the handling is<br />

carried out by a Kuka robot. The Maxx-<br />

Pro screwdrivers are created in three<br />

production steps. Initially, the inserted<br />

blades are picked up by the robot and<br />

placed into the first machine, where<br />

they are injection-moulded with the first<br />

plastic component. The semi-finished<br />

parts are then removed and cooled. The<br />

second and third plastic components<br />

are injected one after the other without<br />

a cooling phase. By expanding its production<br />

in this way, WITTE Werkzeuge<br />

is able to respond to the increased demand<br />

for high-quality screwdrivers.<br />

Frank Rohlfs