NTN - Precision Rolling Bearings

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Technical Data<br />

<strong>NTN</strong>s new bearing life formula<br />

The correlation between the <strong>NTN</strong>s life correction<br />

factor a <strong>NTN</strong> and corrected rating life Lnm is defined by the<br />

formula (3.14) below.<br />

C<br />

p<br />

Lnmaa <strong>NTN</strong><br />

3.14<br />

P<br />

where,<br />

Z<br />

Pmax<br />

Fig. 3.2 Calculation model<br />

Lnm Corrected rating life<br />

a1 Reliability coefficient<br />

a <strong>NTN</strong> Life correction factor that reflects material<br />

properties, fatigue limit stress, contamination<br />

with foreign matter and oil film parameter<br />

() (0.1 a <strong>NTN</strong> 50)<br />

C Basic dynamic load rating<br />

P Dynamic equivalent load<br />

p Index 3 (ball bearing) 10/3 (roller bearing)<br />

(1) Effect of fatigue limit<br />

<strong>NTN</strong>s new bearing life formula introduces a concept<br />

of fatigue life according to which the bearing life is<br />

infinitely long at a particular contact surface pressure as<br />

illustrated in Fig. 3.3 assuming no foreign matter is<br />

trapped in the bearing and the bearing is reliably<br />

lubricated.<br />

y<br />

(2) Effect of foreign matter<br />

The effect of foreign matter is treated as surfaceinitiated<br />

flaking that starts from a dent resulting from<br />

trapped foreign matter. <strong>NTN</strong> performs a bearing life<br />

calculation, assuming that the size of foreign matter and<br />

the stress concentration area in the middle portion (the<br />

size of this area corresponds with that of the foreign<br />

matter) in the surface layer as well as the amount of<br />

foreign matter significantly affect the bearing life.<br />

Dented raceway<br />

Normal raceway<br />

Fig. 3.4 Contact surface pressure distribution resulting<br />

from dent<br />

(3) Effect of oil film parameter ()<br />

The oil film parameter can be used to calculate<br />

bearing life. The oil film parameter, designated by, is<br />

the ratio of the oil film thickness to the roughness of the<br />

surface. It can be used to calculate the average stress<br />

across the surface layer of two contacting surfaces,<br />

such as a rolling element and raceway. From this<br />

surface layer stress, the contact surface pressure can<br />

be determined. Bearing life is then calculated from the<br />

contact surface pressure.<br />

Conditions of two objects on surface layer<br />

Calculation model<br />

Object having<br />

composite roughness<br />

of two objects<br />

Smooth surface<br />

Contact surface pressure<br />

equivalent to fatigue limit<br />

Contact stress<br />

Rating<br />

life<br />

Life reflecting fatigue limit<br />

Life<br />

Fig. 3.3 Basic concept of fatigue limit<br />

Oil film<br />

Fig. 3.5 Model of stress load onto the surface layer<br />

New life calculation formula chart<br />

Various statuses of contamination with foreign matter<br />

are defined in Table 3.2. The values of ISO codes and<br />

NAS classes are those for ball bearings that are<br />

subjected to more severe operating conditions.<br />

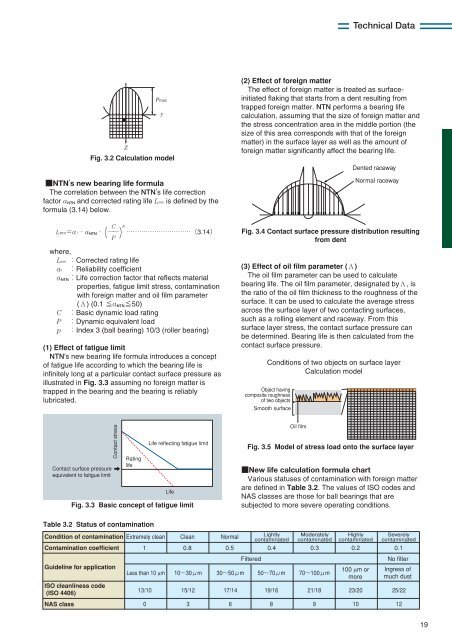

Table 3.2 Status of contamination<br />

Condition of contamination Extremely clean Clean Normal<br />

Lightly Moderately Highly Severely<br />

contaminated contaminated contaminated contaminated<br />

Contamination coefficient 1 0.8 0.5 0.4 0.3 0.2 0.1<br />

Guideline for application<br />

ISO cleanliness code<br />

(ISO 4406)<br />

NAS class<br />

Filtered<br />

Less than 10 μm 1030m 3050m 5070m 70100m<br />

100 μm or<br />

more<br />

No filter<br />

Ingress of<br />

much dust<br />

13/10 15/12 17/14 19/16 21/18 23/20 25/22<br />

0 3 6 8 9 10 12<br />

19