NTN - Precision Rolling Bearings

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Technical Data<br />

(6) Assembly and check of the mounted roller<br />

outside diameter<br />

¡Insert a spacer of widthR. Then insert the inner ring<br />

and mounting spacer and tighten the shaft nut.<br />

¡According to a procedure similar to that in steps (3)<br />

Setting up the mounted internal clearance gage on<br />

the main spindle and (4) Setup of inner ring<br />

clearance, check the mounted roller outside diameter<br />

and the clearance setting. Note this process is only a<br />

re-check procedure, and may be omitted once the<br />

clearance measurements fall in a smaller range.<br />

Clearance correction factor and mounted<br />

internal clearance reading<br />

(1) Clearance correction factor<br />

Because of the structure of the <strong>NTN</strong> mounted internal<br />

clearance adjustment gage, the ratio of the clearance<br />

reading on location for measurement to the reading on<br />

dial indicator is 1:2.5 (clearance indication factor). The<br />

clearance reading on the dial indicator is 2.5 times as<br />

large as the remaining internal clearance. For<br />

reference, a clearance reading conversion table is<br />

given in Table 6.4.<br />

NOTE: Note that the clearance correction factor of certain<br />

bearing numbers is not 1:2.5. Correction factor is<br />

given on the table of inspection results.<br />

(2) Remaining internal clearance (where clearance<br />

indication value 1:2.5)<br />

The reading on the dial indicator is converted into a<br />

mounted internal clearance in the<br />

following manner:<br />

¡CASE 1: The reading relative to the<br />

zero point is in the clockwise<br />

direction (CW) (Fig. 6.25). The<br />

value of the mounted internal<br />

clearance (+) is 1/2.5 times as large<br />

as the reading on dial gage.<br />

Reading on dial gage in Fig. 6.25 = 2.5<br />

Remaining internal clearance = 2.5/2.5 = (+)1m<br />

¡CASE 2: The reading relative to the zero point is in<br />

the counterclockwise direction (CCW) (Fig. 6.26).<br />

The value of the mounted internal clearance (-) is<br />

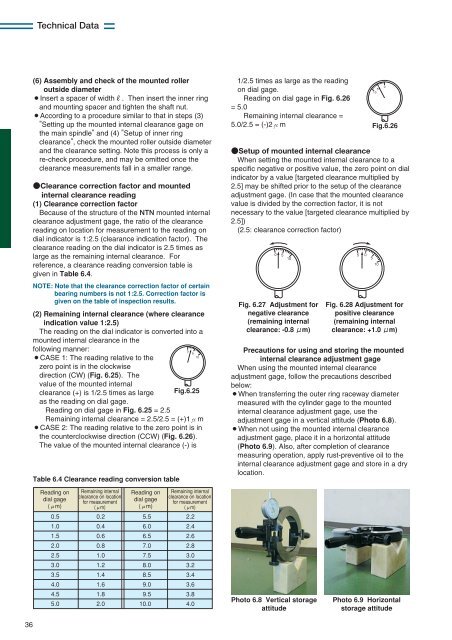

Table 6.4 Clearance reading conversion table<br />

<br />

<br />

<br />

Fig.6.25<br />

1/2.5 times as large as the reading<br />

on dial gage.<br />

Reading on dial gage in Fig. 6.26<br />

= 5.0<br />

Remaining internal clearance =<br />

5.0/2.5 = (-)2m<br />

Setup of mounted internal clearance<br />

When setting the mounted internal clearance to a<br />

specific negative or positive value, the zero point on dial<br />

indicator by a value [targeted clearance multiplied by<br />

2.5] may be shifted prior to the setup of the clearance<br />

adjustment gage. (In case that the mounted clearance<br />

value is divided by the correction factor, it is not<br />

necessary to the value [targeted clearance multiplied by<br />

2.5])<br />

(2.5: clearance correction factor)<br />

<br />

<br />

Fig. 6.27 Adjustment for<br />

negative clearance<br />

(remaining internal<br />

clearance: -0.8 m)<br />

<br />

<br />

Fig. 6.28 Adjustment for<br />

positive clearance<br />

(remaining internal<br />

clearance: +1.0 m)<br />

Precautions for using and storing the mounted<br />

internal clearance adjustment gage<br />

When using the mounted internal clearance<br />

adjustment gage, follow the precautions described<br />

below:<br />

¡When transferring the outer ring raceway diameter<br />

measured with the cylinder gage to the mounted<br />

internal clearance adjustment gage, use the<br />

adjustment gage in a vertical attitude (Photo 6.8).<br />

¡When not using the mounted internal clearance<br />

adjustment gage, place it in a horizontal attitude<br />

(Photo 6.9). Also, after completion of clearance<br />

measuring operation, apply rust-preventive oil to the<br />

internal clearance adjustment gage and store in a dry<br />

location.<br />

<br />

<br />

<br />

Fig.6.26<br />

Reading on<br />

dial gage<br />

(m)<br />

0.5<br />

1.0<br />

1.5<br />

2.0<br />

2.5<br />

3.0<br />

3.5<br />

4.0<br />

4.5<br />

5.0<br />

Remaining internal<br />

clearance on location<br />

for measurement<br />

(m)<br />

0.2<br />

0.4<br />

0.6<br />

0.8<br />

1.0<br />

1.2<br />

1.4<br />

1.6<br />

1.8<br />

2.0<br />

Reading on<br />

dial gage<br />

(m)<br />

5.5<br />

6.0<br />

6.5<br />

7.0<br />

7.5<br />

8.0<br />

8.5<br />

9.0<br />

9.5<br />

10.0<br />

Remaining internal<br />

clearance on location<br />

for measurement<br />

(m)<br />

2.2<br />

2.4<br />

2.6<br />

2.8<br />

3.0<br />

3.2<br />

3.4<br />

3.6<br />

3.8<br />

4.0<br />

Photo 6.8 Vertical storage<br />

attitude<br />

Photo 6.9 Horizontal<br />

storage attitude<br />

36