NTN - Precision Rolling Bearings

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Technical Data<br />

3 Adjustable preload bearing unit<br />

A recent trend in the machine tool industry is a steady<br />

increase of operating speeds. The maximum dmn value<br />

(pitch circle diameter across rolling elements dmmm<br />

multiplied by speed nmin -1 ) reached by main<br />

spindles with air-oil lubricated lubrication can be as high<br />

as 2.5 to 3.8 10 6 . At the same time, main spindles are<br />

requiring increased rigidity. Therefore, main spindle<br />

bearings must be capable of both high-speed operation<br />

and high rigidity. This can be achieved through optimal<br />

preloading.<br />

A fixed preload (spring preload) system is usually<br />

employed to satisfy both these high speed and high<br />

rigidity requirements. A spindle unit with fixed-position<br />

preload that is adjustable for different speed conditions<br />

is advantageous for optimizing the rigidity of the unit.<br />

The <strong>NTN</strong> Adjustable Preload Bearing Unit is a highspeed,<br />

high-rigidity unit that features fixed position<br />

preload that can be adjusted for different speed<br />

conditions.<br />

The <strong>NTN</strong> Adjustable Preload Bearing Unit is<br />

illustrated in Fig. 5.1. Hydraulic pressure is used to shift<br />

the position of the adjustable preload sleeve situated in<br />

the rear bearing section of the unit. This changes the<br />

preload on the bearings.<br />

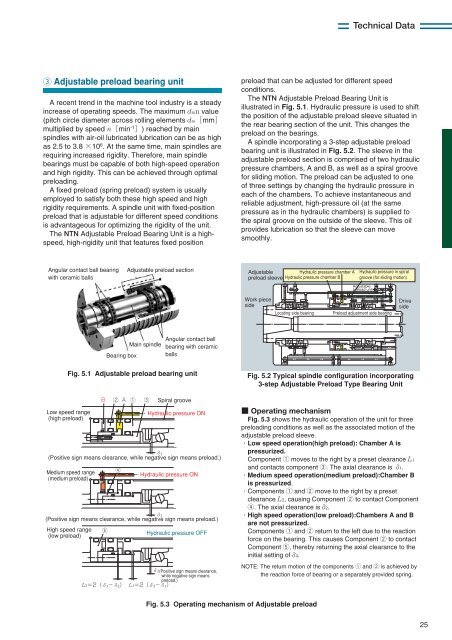

A spindle incorporating a 3-step adjustable preload<br />

bearing unit is illustrated in Fig. 5.2. The sleeve in the<br />

adjustable preload section is comprised of two hydraulic<br />

pressure chambers, A and B, as well as a spiral groove<br />

for sliding motion. The preload can be adjusted to one<br />

of three settings by changing the hydraulic pressure in<br />

each of the chambers. To achieve instantaneous and<br />

reliable adjustment, high-pressure oil (at the same<br />

pressure as in the hydraulic chambers) is supplied to<br />

the spiral groove on the outside of the sleeve. This oil<br />

provides lubrication so that the sleeve can move<br />

smoothly.<br />

Angular contact ball bearing<br />

with ceramic balls<br />

Adjustable preload section<br />

Adjustable<br />

Hydraulic pressure chamber A<br />

preload sleeve Hydraulic pressure chamber B<br />

Hydraulic pressure in spiral<br />

groove (for sliding motion)<br />

Adjustable<br />

preload unit<br />

Work piece<br />

side<br />

Locating side bearing<br />

Preload adjustment side bearing<br />

Drive<br />

side<br />

Bearing box<br />

Main spindle<br />

Angular contact ball<br />

bearing with ceramic<br />

balls<br />

Fig. 5.1 Adjustable preload bearing unit<br />

Low speed range<br />

(high preload)<br />

Medium speed range<br />

(medium preload)<br />

High speed range<br />

(low preload)<br />

<br />

5<br />

2<br />

4<br />

<br />

1 3<br />

Spiral groove<br />

Hydraulic pressure ON<br />

(Positive sign means clearance, while negative sign means preload.)<br />

Hydraulic pressure ON<br />

(Positive sign means clearance, while negative sign means preload.)<br />

Hydraulic pressure OFF<br />

(Positive sign means clearance,<br />

while negative sign means<br />

preload.)<br />

L2 L1 <br />

<br />

<br />

Fig. 5.2 Typical spindle configuration incorporating<br />

3-step Adjustable Preload Type Bearing Unit<br />

Operating mechanism<br />

Fig. 5.3 shows the hydraulic operation of the unit for three<br />

preloading conditions as well as the associated motion of the<br />

adjustable preload sleeve.<br />

Low speed operation(high preload): Chamber A is<br />

pressurized.<br />

Component 1 moves to the right by a preset clearance L1<br />

and contacts component 3. The axial clearance is 1.<br />

Medium speed operation(medium preload):Chamber B<br />

is pressurized.<br />

Components 1 and 2 move to the right by a preset<br />

clearance L2, causing Component 2 to contact Component<br />

4. The axial clearance is2.<br />

High speed operation(low preload):Chambers A and B<br />

are not pressurized.<br />

Components 1 and 2 return to the left due to the reaction<br />

force on the bearing. This causes Component 2 to contact<br />

Component 5, thereby returning the axial clearance to the<br />

initial setting of3.<br />

NOTE: The return motion of the components 1 and 2 is achieved by<br />

the reaction force of bearing or a separately provided spring.<br />

Fig. 5.3 Operating mechanism of Adjustable preload<br />

25