Machinery World - September 2016

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

SEPTEMBER <strong>2016</strong><br />

The No.1 International<br />

Machine Tool Journal<br />

Join us on @<strong>Machinery</strong>W www.machineryworld-online.com

OPTIPLEX NEXUS 3015 FIBER<br />

Compact, high performance laser<br />

processing machine<br />

Large side access<br />

door and flexible<br />

design available with<br />

an automated 2<br />

pallet charger.<br />

OPTIPLEX NEXUS 3015 FIBER is a new entry level fiber laser<br />

processing machine designed for first time buyers with a small<br />

footprint, shorter installation time and KOD ergonomic design.<br />

It utilises a fiber beam delivery system which significantly lowers<br />

operating costs for a wide range of material thicknesses and types.<br />

Multi-Control Torch<br />

provides class leading<br />

flexibillity - standard<br />

equipment.<br />

It’s all about y u<br />

Set-up functions<br />

such as Auto Focus<br />

Positioning, Beam<br />

Diameter Control, Auto<br />

Profiler Calibration and<br />

Auto Nozzle Cleaning -<br />

standard equipment<br />

Yamazaki Mazak U.K. Ltd.<br />

Badgeworth Drive,<br />

Worcester WR4 9NF<br />

T: +44 (0)1905 755755<br />

F: +44 (0)1905 755542<br />

W: www.mazakeu.co.uk<br />

VISIT US ON STAND D26<br />

28 - 29 SEPTEMBER <strong>2016</strong>

CONTENTS<br />

SEPTEMBER ISSUE<br />

AUCTIONS 46–50<br />

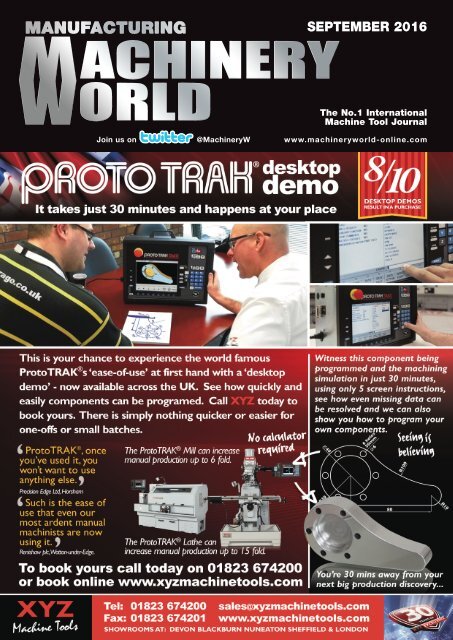

Front Cover:<br />

XYZ Machine Tools<br />

MANAGING DIRECTOR:<br />

Carole Titmuss<br />

NEWS EDITOR:<br />

Pat Fairfax<br />

FEATURES EDITOR:<br />

Danielle Titmuss MSc<br />

SALES:<br />

Tracy Chamberlain<br />

PRODUCTION:<br />

James Kennett; Ian Purves<br />

SUBSCRIPTIONS:<br />

Wendy Burnett<br />

PUBLISHERS:<br />

Carole Titmuss; Tony Prior<br />

This journal includes editorial<br />

photographs provided and paid<br />

for by suppliers.<br />

<strong>Machinery</strong> <strong>World</strong> is available on<br />

subscription annual rate UK £35,<br />

Europe £59, Overseas £80<br />

Single Copies £3.50 UK £6 Overseas<br />

Published by:-<br />

SHEEN PUBLISHING LTD<br />

50 QUEENS ROAD<br />

BUCKHURST HILL<br />

ESSEX IG9 5DD<br />

TELEPHONE: 020 8504 5912<br />

020 8504 1661<br />

International: +44 20 8504 1661<br />

FACSIMILE: 020 8505 4336<br />

International: +44 20 8505 4336<br />

Web:<br />

www.machineryworld-online.com<br />

Email:<br />

machinery@sheenpublishing.co.uk<br />

Twitter:<br />

@<strong>Machinery</strong>W<br />

EXHIBITIONS<br />

AMB Int. Stuttgart 13-17th <strong>September</strong>.<br />

Northern Manufacturing 28-29th <strong>September</strong>.<br />

FEATURES 22–25<br />

CAD/CAM Drives & Controls (Software, Hardware, DROs,<br />

Encoders, Actuators, Chains, Bearings).<br />

NEW PRODUCTS 44–45<br />

SERVICE DIRECTORY 38–41<br />

Our comprehensive guide to Product & Service Providers to the<br />

manufacturing industry.<br />

NEXT MONTH’S EXHIBITIONS<br />

Make Measurement Matter, <strong>2016</strong> – 13th October, Sheffield.<br />

Euroblech, Hanover – 25th-29th October <strong>2016</strong>.<br />

Advanced Engineering Show – 2nd-3rd November, NEC<br />

Birmingham.<br />

NEXT MONTH’S FEATURE<br />

Measurement, Inspection & Quality Control.<br />

ISSN 1745-5898<br />

MACHINERY WORLD is published<br />

monthly and is circulated to senior<br />

personnel who influence the buying<br />

and selling of new and used metal<br />

working machinery worldwide.<br />

©Sheen Publishing Ltd. All rights<br />

reserved. No part of this publication<br />

june be reproduced or transmitted in<br />

any form or by any means, including<br />

photocopying and recording, without<br />

the written permission of the<br />

publishers. Such written permission<br />

must also be obtained before any part<br />

of this publication is stored in a<br />

retrieval system of any nature.<br />

Graham Harris’ quest to replace an ageing bar-fed<br />

lathe with a like-for-like replacement took a new<br />

twist when he saw a gantry-loaded Takisawa Japan<br />

turning centre being demonstrated by T W Ward<br />

CNC <strong>Machinery</strong> (Ward CNC).<br />

Page 8.<br />

ºWith over 25 machines on the shop floor producing<br />

beyond 15 million parts a year, Unicut Precision is<br />

a subcontract manufacturer with a difference.<br />

Page 14.<br />

www.machineryworld-online.com<br />

4 <strong>Machinery</strong> <strong>World</strong>, <strong>September</strong> 2015

Highest Quality -<br />

shortest processing time<br />

100% FANUC - Technology<br />

Watch the video about<br />

FANUC CNC solutions<br />

for advanced machining<br />

here<br />

100% in-house production for maximum reliability<br />

Every component in FANUC CNC systems – laser<br />

sources, controls, motors and amplifiers – is exclusively<br />

developed, manufactured and tested to perfection<br />

in-house. Designed for utmost compatibility, these parts<br />

are extremely long lived, making for very high levels of<br />

machine uptime as well as a mean time between<br />

failures of well over fifteen years.<br />

Find out more about FANUC CNC systems<br />

fanuc.co/cnc-en<br />

marketing@fanuc.co.uk | ref.MW0816<br />

<strong>Machinery</strong> <strong>World</strong>, <strong>September</strong> <strong>2016</strong> 5

NEWS NEWS NEWS<br />

ARE YOU PREPARED FOR THE ROAD AHEAD<br />

Seco Tools UK’s ‘Inspiration through<br />

Innovation’ advanced manufacturing bestpractice<br />

event is taking place at the<br />

company’s Technology Centre in Alcester, on<br />

<strong>September</strong> 21st & 22nd.<br />

Now in its third year, the event provides<br />

manufacturers with the opportunity to see,<br />

first-hand, a number of innovative and<br />

challenging machining demonstrations…to<br />

attend a series of leading-edge seminars,<br />

focused this year on Industry 4.0 issues and<br />

developments…and to visit over 40 different<br />

Technical Partner stands - each showcasing<br />

the very latest manufacturing technologies<br />

and solutions.<br />

Explains Mike Fleming, Seco Tools UK’s<br />

Sales & Marketing Manager:<br />

“To ensure our Inspiration through<br />

Innovation remains current, relevant and<br />

continues to capture the imagination of<br />

manufacturers, we have created a theme for<br />

this year’s event.<br />

“One of the hot topics in manufacturing<br />

(now and in the future) is Industry 4.0.<br />

“There’s a lot of hype surrounding the<br />

issue, and we wanted to simplify matters by<br />

devoting our whole Seminar Programme (at<br />

the event) to providing detailed explanations<br />

and outlining the implications for all<br />

TRADE MOULDER ADDS<br />

TWO NEW ROMI PLASTIC<br />

INJECTION MACHINES<br />

Skar Precision Mouldings has installed two new plastic injection<br />

moulding machines, both Romi models. The EN 300 and EN 70<br />

replace older technology and will be used to produce a wide range of<br />

components for sectors that include medical, engineering, point of<br />

sale and retail.<br />

The company already had seven Romi (formerly Sandretto)<br />

plastic injection moulding machines which were taken on secondhand<br />

through acquisition of other plastic moulders. This year when<br />

it took quotes for new machines it was surprised just how<br />

competitively priced the Romi machines were and so it made the<br />

decision to buy new.<br />

“Seven of our 40 plus machines are Romi models and we know<br />

the machines will do what they say they will do and that they are<br />

robust and will work across a wide range of thermoplastic materials.<br />

The two new machines replace a 1986 Sandretto and an ageing<br />

Arburg and will give us greater control and reduce our energy usage.<br />

The capital cost and running costs were very convincing,” says Paul<br />

Denny, operations director at the trade plastic injection moulding<br />

business in Hadleigh, Suffolk.<br />

“We even have remote diagnostics which would allow Romi to<br />

dial up via the Internet to intervene if there was an issue. We haven’t<br />

needed that to date and don’t expect to need it but it is peace of<br />

mind,” he says.<br />

Web: www.Romiuk.com<br />

manufacturers about what industry<br />

commentators are calling The Fourth<br />

Industrial Revolution’.<br />

“The eight seminars taking place over the<br />

two days include keynote presentations from<br />

The EEF and The AMRC, as well as from<br />

leading experts from Seco.”<br />

Whilst the seminars will undoubtedly<br />

pull in the crowds, the event also includes 12<br />

challenging live machining demonstrations<br />

from Technical Partners - DMG Mori, Fanuc,<br />

Geo Kingsbury, Grob, Romi and Spinner.<br />

The mainstay of the event involves the<br />

40+ Technical Partners, which include<br />

leading machine tool builders and best-inclass<br />

CAD/CAM, work-holding, tooling,<br />

automation, CNC Training, cutting fluid, and<br />

metrology and inspection solution<br />

specialists, showcasing and demonstrating<br />

their latest products and technologies to<br />

visitors.<br />

‘Inspiration through Innovation’ is very<br />

much focused on the future and is aimed at<br />

precision component manufacturers looking<br />

to get out more from their manufacturing<br />

processes, systems and people. The emphasis<br />

throughout reflects Seco’s ethos that a<br />

collaborative approach to problem-solving<br />

and sharing best practice with customers<br />

deliver inspirational and innovative<br />

solutions.<br />

Manufacturers wishing to attend Seco’s<br />

Inspiration though Innovation event can<br />

register by visiting Seco’s website<br />

www.secotools.com/gb<br />

MOLLART SECURES<br />

£2 MILLION EXPORT ORDERS<br />

\Export gundrilling machine orders worth over £2 million have been<br />

won by Mollart Engineering for nine machines destined for<br />

European and Chinese automotive industry customers. The<br />

contracts from Poland, Czech Republic, Romania, China and<br />

northern Europe has set the company well into its machine build<br />

target for <strong>2016</strong>-17 with projected extensions into 2018.<br />

Said Sales Director Ian Petitt: “These are very significant orders<br />

for new machines taken against very tough European competition<br />

with customers focusing on our project and application engineering.<br />

In one case, the final approval decision towards Mollart was aided by<br />

our long term production history of machine reliability, spindle<br />

utilisation and customer support on two previous Mollart<br />

installations in the company.”<br />

These orders add a high level of confidence to the new<br />

management team of Chris Barker, Ian Petitt, Mike Pragnell, Wayne<br />

Thomas and Jon Upton, who successfully acquired the Mollart<br />

business in March with the backing of HSBC and Vine Street Capital<br />

from the long term family-owned business of Guy Mollart.<br />

Tel: 0208 391 2282<br />

Email: mark.dore@mollart.co.uk Web: www.mollart.com<br />

6 <strong>Machinery</strong> <strong>World</strong>, <strong>September</strong> <strong>2016</strong>

NEWS NEWS NEWS<br />

BySTRONIC OPEN<br />

HOUSE SUCCESS –<br />

THREE LASER<br />

CUTTING<br />

MACHINES SOLD<br />

Sheet metalworking machine supplier,<br />

Bystronic UK, welcomed more than 80<br />

visitors to its latest open house, held at the<br />

company's Coventry headquarters and<br />

technical centre from 12th to 14th July.<br />

During the week of the event, orders were<br />

placed for three laser cutting machines,<br />

indicating that UK manufacturing still has a<br />

positive outlook post-Brexit.<br />

Bystronic’s latest fibre laser machine was<br />

on show, the ByStar Fiber, which boasts<br />

Industry 4.0 readiness and a new control<br />

system. The machine has been designed from<br />

the ground up to move a fibre optic cutting<br />

head across the laser bed as efficiently as<br />

possible. A full length sliding door allows<br />

users to remove rush jobs or inspect<br />

components from the side at any time, even<br />

when large orders are running, which is a big<br />

advantage for job shops as they need to be<br />

flexible.<br />

Another focus at the open house was on<br />

pressbrake operation. Theoretical and<br />

practical presentations throughout the<br />

mornings on Bystronic Xpert machines<br />

introduced visiting engineers to tips and<br />

tricks for saving time and increasing<br />

productivity and component accuracy.<br />

The company also highlighted improved<br />

ergonomics on the Xpert 40 pressbrake,<br />

which can now be equipped with a heightadjustable,<br />

22-inch touch screen.<br />

The redesigned generation of BySprint<br />

Fiber 3015 and 4020 laser cutting systems was<br />

also promoted. It has an extended<br />

performance package that includes<br />

additional functions in the basic version. The<br />

machines can now be controlled from a 22-<br />

inch touch screen, allowing the operator to<br />

load the cutting plans with a few swipes of a<br />

finger. In the background, the software<br />

accesses an extensive database containing<br />

cutting parameters for all common sheet<br />

metal materials and thicknesses. Taking the<br />

component geometry into account, it<br />

generates the ideal cutting process.<br />

In addition, Bystronic has expanded the<br />

basic version of the BySprint Fiber with three<br />

powerful additional functions to deliver<br />

more performance at no extra cost.<br />

Tel: 08448485850<br />

Email: david.larcombe@bystronic.com<br />

Web: www.bystronic.com<br />

FUCHS LAUNCHES NEXT GENERATION<br />

COOLANT<br />

FUCHS Lubricants has unveiled a<br />

groundbreaking metalworking fluid which<br />

significantly increases tool life and boosts<br />

productivity.<br />

FUCHS ECOCOOL ULTRA-MOTIVE has<br />

been described by the manufacturer as “the<br />

greatest development in soluble<br />

metalworking fluids for a generation”.<br />

The product, which builds on FUCHS’<br />

unique patent-pending ‘GLOBAL’<br />

technology, was officially launched at the<br />

MACH Exhibition.<br />

The novel platform chemistry has been<br />

developed to provide excellent levels of<br />

lubricity, cooling and corrosion protection,<br />

whilst being free of boron and other SVHCregistered<br />

components.<br />

FUCHS ECOCOOL ULTRA-MOTIVE has<br />

been benchmarked against many competitor<br />

products. Customers have reported over 40<br />

per cent reduction in tooling costs when<br />

using the latest Fuchs technology. Greater<br />

savings can be realised when tools are<br />

optimised for the process.<br />

In tooling tests with titanium alloys, tool<br />

life increases of 150 per cent were recorded.<br />

ECOCOOL ULTRA-MOTIVE is suitable<br />

for machining ferrous materials including<br />

cast iron, stainless steels, Duplex, Super<br />

Duplex and alloys of aluminium, nickel and<br />

Graham Harris’ quest to replace an ageing<br />

bar-fed lathe with a like-for-like replacement<br />

took a new twist when he saw a gantryloaded<br />

Takisawa Japan turning centre being<br />

demonstrated by T W Ward CNC <strong>Machinery</strong><br />

(Ward CNC).<br />

While he was suitably impressed with the<br />

machine’s billet handling capabilities, he<br />

didn’t want to forego bar-fed work since<br />

around 85 per cent of the throughput is<br />

derived from bar at his company, precision<br />

machinist Harris RCS.<br />

titanium.<br />

Extensive in-house testing took place on<br />

FUCHS’ own CNC machine tool. Cutting<br />

speeds were increased to provide real<br />

benefits in productivity while maintaining<br />

excellent tool life.<br />

The rate of metal removal can also be<br />

increased. Results indicate a 16 per cent<br />

increase in cutting speed is possible when<br />

matching the tool life of FUCHS’ previous<br />

class leading product, ECOCOOL<br />

ULTRALIFE A.<br />

The product is designed for use in both<br />

hard and soft water with a wide range of<br />

materials allowing effective product<br />

rationalisation and a reduction in complexity<br />

for all automotive manufacturers and similar<br />

industries.<br />

Web: www.fuchslubricants.com<br />

MODIFIED TAKISAWA JAPAN TURNING<br />

HANDLES BAR AND BILLET WORK FOR<br />

HARRIS RCS<br />

So, Ward CNC simply modified the<br />

machine so that it could process both bar and<br />

billet work – with the result that the<br />

Takisawa Japan TCC-2000GAL3 singlespindle<br />

turning centre is now successfully<br />

machining a range of parts at the longestablished<br />

company based in Coventry.<br />

Mr Harris explains: “With a number of<br />

other Ward CNC-supplied/supported<br />

machines onsite – Hyundai Kia lathes and<br />

vertical drilling and tapping centres - I am, of<br />

course, fully conversant with Ward CNC’s<br />

service and back up, and when looking to<br />

update one of our older bar-fed lathes I<br />

obviously opened discussions with Ward<br />

CNC.<br />

“I was impressed with the Takisawa<br />

Japan machine and its automatic billet<br />

loading but, because much of our work is<br />

from bar, I hesitated about investing a<br />

machine which on that basis, might have<br />

stood idle for much of the time. That<br />

dilemma was immediately resolved when<br />

Ward CNC offered to modify the machine,<br />

using a Hydrafeed MV65 short magazine<br />

system, and adapt it for bar work, too.”<br />

Tel: 0114 276 5411<br />

Email: lwilson@wardcnc.com<br />

Web: www.wardcnc.com<br />

8 <strong>Machinery</strong> <strong>World</strong>, <strong>September</strong> <strong>2016</strong>

MACHINE TOOL ACCESSORIES<br />

Workholding<br />

for 5 axis<br />

machines?<br />

The answer’s<br />

YES<br />

Technomagnete workholding and lifting<br />

solutions. From 1st MTA, the UK’s<br />

leading machining accessories supplier.<br />

St<br />

Email: enquiries@1mta.com Freephone: 0800 783 0510<br />

Fax: 0800 783 0517 www.1mta.com<br />

MTA

NEWS NEWS NEWS<br />

TWO LATEST CITIZEN L32 TURN-MILL CENTRES<br />

MEET OIL AND GAS DEMANDS AT ALCO VALVES<br />

Two of the very latest ‘icon’ versions of the<br />

full specification Citizen Cincom L32-VIII<br />

CNC sliding head turn-mill centres feature as<br />

part of the first of the extensive machine tool<br />

installations in the new manufacturing plant<br />

relocation plans of the Alco Valves Group.<br />

Alco Valves Group’s new, purpose<br />

designed 68,000 ft2 flagship headquarters<br />

which has seen an investment of $10 million<br />

on an 8.5 acre site in Brighouse, West<br />

Yorkshire, will progressively integrate three<br />

existing sites, in order to centralise product<br />

design and research as well as the<br />

development, production, final assembly and<br />

test of oil and natural gas valves.<br />

Acquired by American conglomerate<br />

Graco Inc. in 2014, a world leader in fluid<br />

handling equipment, Alco Valves has<br />

become a key part of Graco’s oil and gas<br />

division. The decision to purchase the Citizen<br />

machines against competitor sliding head<br />

machines involved not only a team from the<br />

UK but also engineers from America.<br />

Together, they jointly performed in-depth<br />

investigations of the technology and the<br />

potential capability to meet future<br />

production requirements.<br />

Major advantages also cited in the<br />

justification and decision for the Citizen<br />

machine installations were factors such as<br />

reliability plus ease-of-use and high levels of<br />

flexibility for processing the company’s type<br />

of work. Once the joint decision was made,<br />

the US team also placed orders for identical<br />

machines to perform similar turn-milling<br />

requirements for parts up to 32 mm<br />

diameter.<br />

The two Citizen machines, which were<br />

installed in a cell in late February, are being<br />

progressively tooled for producing valve<br />

bodies, inserts, end connectors, stems and<br />

seals using materials including 316 stainless<br />

steel, duplex and PEEK. Cycle times at the<br />

moment vary between 30 secs for seats to 5<br />

minutes for valve bodies.<br />

Mr Stonier commented: “This was our<br />

first venture into sliding head technology as<br />

these parts up to 32 mm diameter were<br />

previously made on subcontract. This means<br />

our focus has been on building our own very<br />

cost-efficient programs that will reduce our<br />

lead times.<br />

Tom Stonier, UK Manufaturing Engineer<br />

Manager, described how the acceptance trials<br />

of both machines were carried out without a<br />

hitch and all the run-off criteria was easily<br />

exceeded.The Alco Valves machines have an<br />

IEMCA bar feed and outfeed component<br />

conveyor, Citizen’s Coolblaster CB50 high<br />

pressure coolant system and Absolute<br />

filtration. An external coolant tank is<br />

included with integrated swarf conveyor that<br />

has an air curtain under the conveyor outlet<br />

to prevent any small swarf particles being<br />

carried back along the load length of the<br />

conveyor. Both machines are linked into a<br />

wireless network that will cover all machine<br />

tools in the facility.<br />

Tel: 01923 691500<br />

Web: www.citizenmachinery.co.uk<br />

FICEP STEEL PROCESSING EQUIPMENT FORMS PART OF A<br />

SUBSTANTIAL INVESTMENT<br />

AJN is a forward thinking, independently<br />

owned steel stockholder that was originally<br />

operating from the one 11 acre site in Kentford<br />

near Newmarket, but recently they have<br />

opened an even larger 17 acre depot in<br />

Henstridge in Somerset.<br />

This substantial new £13 million<br />

investment included the construction of the<br />

new site, 22 combi forklifts, 16 trucks with £5<br />

million of the overall total being spent on new<br />

FICEP steel processing machinery.<br />

From the very start AJN were looking to<br />

source all the machines from the one supplier<br />

to ensure continuity of support. It was only<br />

after in-depth research by AJN and numerous<br />

trips around world to access the different<br />

machine manufacturers and visiting many sites<br />

that the decision was made to go with FICEP.<br />

At the long established Kentford site has a<br />

daily turnover is around 350 tons of steel. The<br />

new Henstridge site total is growing rapidly<br />

month by month with the goal to achieve 500<br />

tons per day within 5 years by increasing shift<br />

patterns from 1 to 3 to fully exploit the<br />

potential of the FICEP steel processing<br />

machinery.<br />

From the first order placed, the FICEP<br />

machines were delivered and installed and<br />

commissioned on time and were operational<br />

within 3 months. The 8 new FICEP machines<br />

in operation at AJN include an Endeavour - a<br />

multi-spindle drilling line, the Gemini - the<br />

gantry drilling, milling and thermal cutting<br />

system for plates, several Katana - high speed<br />

bandsaws, the Rapid - high speed drilling line<br />

for angles and flats and a shot blasting<br />

machine and a second Endeavour machine<br />

was purchased for the Kentford facility.<br />

A detailed time study analysis determined<br />

that a 48 minute job on the old machinery now<br />

takes under 5 minutes on the Endeavour and<br />

is 4 times faster when drilling only.<br />

Productivity has been further enhanced by the<br />

Gemini which is the most versatile machining<br />

centre for the processing of plate products.<br />

The Rapid now allows AJN to drill and cut<br />

angles which is a new service they can offer<br />

their customers.<br />

The Henstridge site now covers the whole<br />

of southern England and their customers are<br />

already benefiting from AJN’s increased<br />

productivity and lower production costs - it’s<br />

a win, win scenario for both parties.<br />

Courtney Bell, Finance Director of AJN<br />

had this to say “When we decided to expand<br />

the into a new site we were looking for the<br />

very best equipment available. FICEP were<br />

the ones who offered us the best solutions<br />

after a considerable review of existing and<br />

new suppliers.<br />

The Endeavour proved to be the ultimate<br />

solution for drilling and sawing, on top of this,<br />

the Rapid 25 we purchased allowed us to<br />

secure a large amount of new business. In<br />

buying several machines from FICEP<br />

including the Gemini, Katana Saws and one of<br />

the UK’s largest roller conveyor shotblasters,<br />

the capacity and performance in the new<br />

facility has exceeded all expectations. FICEP<br />

has lived up to all our requirements in terms<br />

of delivery, commissioning, machine<br />

capability and customer support.”<br />

Tel: +44 (0)1924 223530<br />

Email: info@ficep.co.uk<br />

Web: www.ficep.co.uk<br />

10 <strong>Machinery</strong> <strong>World</strong>, <strong>September</strong> <strong>2016</strong>

NEWS NEWS NEWS<br />

cnf buys<br />

maTsuura as<br />

“posT brExiT”<br />

ExporTs groW<br />

CNF Precision has just bought its fourth<br />

Matsuura machining centre to cope with<br />

growing 'Post-Brexit' demand from<br />

customers in the US and China. The new<br />

Matsuura MX-520 5-axis machining centre<br />

will be delivered in <strong>September</strong>.<br />

The Aylesbury based subcontractor has<br />

many high end machine tools on the shop<br />

floor that already include a 32-pallet<br />

Matsuura MAM72-35V 5-Axis, two<br />

Matsuura H.Plus-300 PC15 Pallet horizontal<br />

machines, Nakamura multi Axis Mill/Turn<br />

and Citizen Sliding Heads. They are also<br />

aerospace approved to AS9100 and ISO9001.<br />

With many of its machine tools geared for<br />

volume production, the latest Matsuura MX-<br />

520 has been added to the CNF plant list to<br />

further enhance prototyping and small batch<br />

production capacity.<br />

Commenting on the purchase, CNF<br />

Precision's Managing Director, Mr Neil<br />

Fearnley says: "The addition of the Matsuura<br />

5-axis will enable us to rapidly turnaround<br />

complex prototypes. By extending our 5-axis<br />

prototyping and small batch capability, we<br />

will have the facility to win more long term<br />

production contracts that arrive off the back<br />

of turning out more prototype projects."<br />

The aim of turning out more prototypes,<br />

and consequently winning more long term<br />

projects, is a result of CNF's export business,<br />

as Mr Fearnley continues: "Our work for non-<br />

EU countries continues to increase and we<br />

are confident that the Brexit vote will have a<br />

positive impact on our export business as<br />

trade agreements with the UK are established<br />

across the world. Unfortunately the mainstream<br />

media organisations are intent on<br />

talking the UK into recession. I certainly<br />

wouldn't have made such a considerable<br />

investment in the new Matsuura, had I not<br />

been optimistic about the prospects for UK<br />

manufacturing moving forward."<br />

Tel: 01296 481727<br />

Email: sales@cnfengineering.com<br />

Tel: 01656 738566<br />

Email: michie@matsuuma.co.uk<br />

forTh gEnEraTion<br />

TakEs on nEW challEngEs<br />

French & Son is a household name in<br />

Heathfield, Sussex as for over three<br />

generations it has served the local<br />

community with garage and taxi services.<br />

While these businesses continue to thrive,<br />

fourth generation Charlie French is looking<br />

in a different direction to keep the family<br />

business expanding, making full use of his<br />

motorsport connections.<br />

Charlie’s involvement with motorsport,<br />

including assisting in the pits as a mechanic<br />

for some Rally Cross teams, as well as racing<br />

his own bright green Ford Escort mk2 at<br />

track days led him away from the family<br />

businesses to work for engine builder and<br />

British Rally Cross Champion Julian<br />

Godfrey, whose engineering company is just<br />

up the road from French & Son Engineering.<br />

After eight years with Julian, Charlie had<br />

become familiar with the operation of the<br />

XYZ machines used so, with the support of<br />

his father Stuart, decided to set up his own<br />

manufacturing business.<br />

Initially focussing on supplying<br />

aftermarket parts for car and motorcycle<br />

enthusiasts, French & Son Engineering took<br />

space in a local industrial unit and invested<br />

in an XYZ 710 VMC vertical machining<br />

centre. That was in February <strong>2016</strong>. Since then<br />

the reputation of Charlie French and his<br />

ability to problem solve and add value to<br />

existing components, has brought him to the<br />

attention of several businesses who are<br />

putting work his way.<br />

The choice of XYZ Machine Tools for<br />

French & Son’s move into machining was<br />

influenced by Charlie’s experience with<br />

Julian Godfrey. In terms of experience<br />

Charlie is virtually self-taught in both<br />

Dynashape, the experienced sawblade<br />

servicing and manufacturing specialist, has<br />

secured a new 12-month contract with<br />

Britain’s largest specialist cold roll-forming<br />

company, voestalpine Metsec plc.<br />

The contract is for the supply of TIALNcoated<br />

SHSS (Super High Speed Steel) and<br />

TCT (Tungsten Carbide Tipped) sawblades,<br />

as well as for sawblade remanufacturing.<br />

“This will be the second year that we have<br />

provided sawblade services for Metsec,”<br />

comments Dynashape’s Managing Director,<br />

Chris Parkes, “and I am absolutely delighted<br />

that the team at Metsec has chosen to appoint<br />

us again. When we first won the business in<br />

2015, we demonstrated how our sawblades<br />

were capable of delivering in the region of<br />

3,000 cuts per blade. That’s around 900 more<br />

cuts per blade than Metsec was achieving<br />

using a competitor’s products. More<br />

importantly, it underlines the true cost<br />

effectiveness of the improved sawblade<br />

technology that is employed by Dynashape.”<br />

Providing Metsec with sawblades that<br />

CADCAM and machine operation. Up until<br />

purchasing the XYZ 710 VMC he had<br />

received no formal training and even now<br />

has only taken two of his allocated training<br />

days from XYZ on the new machine. The<br />

XYZ VMC is central to the XYZ VMC range<br />

and provides impressive capability at a very<br />

competitive price. As standard it is equipped<br />

with a 20 hp, 8000 revs/min, BT40 spindle<br />

axis travels of 710 x 450 x 500 mm, with<br />

performance enhanced through use of a 4000<br />

kg solid ribbed casting in its construction.<br />

“We know we have a long way to go, but<br />

our plans are to achieve more in the next 12<br />

to 18 months in order to allow us to carry out<br />

our expansion plan,” says Charlie French. “In<br />

addition, we hope to develop our own<br />

product range by enhancing existing<br />

aftermarket motorsport parts, developing<br />

them to improve their performance and<br />

longevity for customers. For our business to<br />

business expansion, we see our ability to<br />

work with customers to enhance their<br />

current products by helping to reduce<br />

weight, improve performance and lower<br />

manufacturing costs.<br />

Tel: 01823 674200<br />

Email:<br />

nigel.atherton@xyzmachinetools.com<br />

Web: www.xyzmachinetools.com<br />

dynashapE providEs rEal bEnEfiTs<br />

for mETsEc<br />

have a much longer life, however, really is<br />

only part of the story. Dynashape’s<br />

considerable investment in the latest CNC<br />

sawblade manufacturing technologies – the<br />

same machinery that is used by leading<br />

sawblade producers globally – means it is<br />

also able to remanufacture Metsec’s blunt<br />

blades to ‘as new’ standards.<br />

Dynashape is part of the Addison Group,<br />

a UK-based organisation that has been at the<br />

forefront of metal sawing technology since<br />

1956.<br />

Tel: 01384264950<br />

Email: news@addisonsaws.co.uk<br />

Web: www.addisonsaws.co.uk<br />

12 <strong>Machinery</strong> <strong>World</strong>, <strong>September</strong> <strong>2016</strong>

NEWS NEWS NEWS<br />

PRODUCTIVITY IS MORE ‘FLUID’ FOR<br />

UNICUT WITH HOUGHTON OILS<br />

ºWith over 25 machines on the shop floor<br />

producing beyond 15 million parts a year,<br />

Unicut Precision is a subcontract manufacturer<br />

with a difference. With a variety of high-end<br />

fixed and sliding head turning centres, Unicut<br />

prides itself on investment state-of-the-art<br />

technology.<br />

This investment drive has recently seen the<br />

Welwyn Garden City machine shop invest over<br />

£760,000 in six Citizen sliding head machines<br />

and a fixed head Miyano BNA 42SY turning<br />

centre. Running its machine shop 24 hours a<br />

day, Unicut considers itself a 'contract<br />

manufacturer' that works in tandem with<br />

OEM's and Tier 1 companies to deliver costdown<br />

production philosophies to long term<br />

projects. It is this partnership with globally<br />

renowned companies that led Unicut to<br />

implement cutting fluids from Houghton<br />

International.<br />

Commenting upon the new relationship,<br />

Houghton's Business Development Manager,<br />

Mr Kevin Lambdon says: "We are a key supplier<br />

As the summer already draws to a close, surface<br />

finishing and deburring experts Ellesco will be<br />

looking to put a shine into the first month of<br />

Autumn with the announcement of its Open<br />

House Event from the 20th to 22nd of<br />

<strong>September</strong>. If you have components that require<br />

deburring or surface finishing, Ellesco is<br />

inviting you to bring along your problem parts<br />

to trial on the Grindingmaster Timesaver<br />

machines.<br />

The event at the Ellesco facility in<br />

Christchurch will be a great opportunity to see<br />

four of the latest machines from Timesavers<br />

whilst an abrasives expert from Hermes Coated<br />

Abrasives will be on hand to discuss the<br />

technical elements and benefits of its range of<br />

abrasive belts, brushes and consumables. For<br />

customers making a concerted effort to visit the<br />

scenic New Forest area on the South Coast and<br />

also get an education in first class surface<br />

finishing, Ellesco will be hosting entertainment<br />

evenings for customers.<br />

The four Timesavers machines at the event<br />

will include the Timesavers 10 Series<br />

1300MGVT, the 12 Series 600WB, the 22 Series<br />

900W and the extremely popular 42 Series WRB<br />

machine. Alongside the new products, Ellesco<br />

will have a complete range of cost-effective<br />

used and refurbished surface finishing<br />

machines available for immediate delivery.<br />

‘OPEN ALL HOURS’<br />

to many global OEMs and at an Eaton<br />

Hydraulics Global Supplier convention, one of<br />

our key account managers met Unicut's MD, Mr<br />

Jason Nicholson. The relationship evolved and<br />

now we supply Unicut with a series of cutting<br />

oils and fluids."<br />

Initially, Houghton was invited to Unicut to<br />

conduct a site survey to evaluate the machine<br />

tools, processes and the materials being<br />

machined. With this information the company<br />

applied the best-fit fluid for the fixed and<br />

sliding head turning centres.<br />

With the partnership between Houghton<br />

and Unicut approaching its first birthday, the<br />

Production Supervisor at Unicut Precision, Mr<br />

Gary Garner says: "The Houghton products are<br />

excellent. We get next day delivery, the quality<br />

of the oil is outstanding and it's extremely cost<br />

effective. With regards to performance the oil is<br />

noticeably improving our tool life with<br />

improvements beyond 25% already being<br />

recorded.<br />

Commenting upon the production<br />

scheduling and how the new machines run at<br />

Unicut, company MD, Mr Jason Nicholson<br />

concludes: "Our sliding heads typically run<br />

batches from 50 to 50,000 parts around the<br />

clock, and three of the new machines have<br />

already been committed to OEM customers and<br />

their long term production needs. Running on<br />

this basis, machine utilisation rates are core to<br />

our success. The Houghton oils are improving<br />

our uptime and reducing our tooling<br />

consumption and the consequent tool<br />

changeovers. This is a huge benefit to a business<br />

like Unicut."<br />

Tel: 0161 8745000<br />

Email: matthew.bartle@houghtonintl.com<br />

The focal point of most Open House events<br />

and exhibitions is the ever popular Timesavers<br />

42 Series. At the <strong>September</strong> event, Ellesco will<br />

be putting the 1350WRB variant through its<br />

paces on customer parts. With a wide abrasive<br />

belt for the pre-grinding removal of heavy burrs<br />

from parts and a follow-up multi-directional<br />

brush that uniformly deburrs and finishes<br />

edges of laser cut, punched and machined parts<br />

in a single pass; its no surprise the 42 Series<br />

WRB is one of Ellesco's best selling machines.<br />

Tel: 01202 499400<br />

Email: g.newton@ellesco.co.uk<br />

Web: www.ellesco.co.uk<br />

QIMTEK<br />

INDUSTRY ROUND UP<br />

TREASURY TO SAFEGUARD<br />

EU RESEARCH FUNDING<br />

The UK’s Business and Energy Minister has<br />

said that the government’s commitment to<br />

science research ‘remains steadfast’, with the<br />

Treasury confirming that funding for<br />

approved Horizon 2020 projects will be<br />

underwritten.<br />

As a result, British businesses and<br />

universities will now have certainty over<br />

future funding, even beyond the UK’s<br />

departure from the EU. The Horizon 2020<br />

programme has provided funding to a<br />

number of innovative British research ideas<br />

to help bring them to the market more<br />

swiftly, totalling around €2 billion.<br />

To find out more about the government’s<br />

promise, head here:<br />

http://ow.ly/URTF303jqxs<br />

COULD A BRIGHT FUTURE<br />

BE AHEAD FOR UK<br />

MANUFACTURING<br />

POST-BREXIT?<br />

Almost 2 months on from the UK’s decision<br />

to leave the EU, one of the biggest questions<br />

facing the country is whether our industry<br />

has the strength to thrive in a post-Brexit<br />

economy. How could this opportunity be<br />

used to create a more profitable era for<br />

manufacturing?<br />

One positive in recent months is that<br />

British-made products have seen resurgence<br />

in appeal, and with the fall in sterling,<br />

companies selling abroad could face a<br />

welcome boost. As well as this, the Prime<br />

Minister has assured the country of her<br />

commitment to manufacturing and industry,<br />

with research funding guaranteed and the<br />

possibility of securing new investment deals<br />

with other countries also.<br />

To find out more on how UK<br />

manufacturing could thrive, head here:<br />

http://ow.ly/9jyj303jqBB<br />

3D PRINTING REVENUE<br />

SET TO DOUBLE<br />

According to IDC, a global provider of<br />

market research, global 3D printing revenue<br />

will surge from $15.9bn this year to $35.4bn<br />

in 2020.<br />

The growing list of 3D printing<br />

capabilities is set to “enable the next wave of<br />

customer innovation in discrete<br />

manufacturing, product design, and life<br />

sciences,” according to Christopher Chute,<br />

vice president of customer insights and<br />

analysis at IDC. Automotive design is<br />

expected to make up the biggest share of<br />

revenue, followed by healthcare and<br />

professional services.<br />

You can read more on the latest comments<br />

by heading here:<br />

http://ow.ly/4AkD303jqCE<br />

14 <strong>Machinery</strong> <strong>World</strong>, <strong>September</strong> <strong>2016</strong>

+44 (0)116 298 8636<br />

1<br />

2<br />

3<br />

4<br />

ESAB A6 Submerged Arc Welding<br />

Tractor with PFG1 Controls<br />

& ESAB LAE 800 amp Power Source.<br />

Fronius<br />

TIME 5000<br />

Digital<br />

MIG Welder,<br />

Water<br />

cooled<br />

package.<br />

ESAB ID50 Internal Seam Welder,<br />

High quality longitudinal welds to<br />

tanks, vessels or cylinders.<br />

Messer OmniMat 400 CNC Plasma &<br />

Oxy Fuel Profiler Cutter Extraction<br />

system & Kjellberg HiFocus 360i<br />

Plasma.<br />

5<br />

6<br />

7<br />

HIRE ME<br />

8<br />

HIRE ME<br />

HIRE ME<br />

Esprit D1500 CNC HD HyDefinition<br />

cutting system Hypertherm HPR<br />

130 plasma<br />

AMI Orbital Welding Systems<br />

107, 207, 227 415 models Tube to<br />

tube/sheet. For Sale or Hire<br />

New Welding Positioners<br />

Capacity 500kg - 5,000kg<br />

For Sale or Hire<br />

New Welding Pipe Rotators<br />

Capacity 1,000kg - 30,000kg<br />

For Sale or Hire

NEWS NEWS NEWS<br />

ITALIAN TOOL MAKER CUTS LEAD TIMES<br />

WITH BLUM NOVOTEST<br />

The production of high-quality aluminium<br />

extrusion tools is an art unto itself. Only few<br />

companies match the precision and quality<br />

with which the Italian Alumat-Almax-<br />

Matrex masters this process. Through the<br />

introduction of Blum Novotest laser<br />

measurement and touch probes in its<br />

machining centres, the manufacturing time<br />

can be reduced significantly and the accuracy<br />

of the products has significantly improved.<br />

Alumat was founded in Ciserano near<br />

Bergamo in Italy in 1994. It employs about<br />

fifty staff in the design and manufacture of<br />

steel dies for aluminium extrusion. The<br />

continuous growth led to an expansion of the<br />

business resulting in increased production<br />

capacity and a tripling of sales within 4 years.<br />

“The special thing about our activities is<br />

the fact that our tools are essentially<br />

individual items created specifically for our<br />

customers. Not only do we supply individual<br />

dies, but also the entire planning and<br />

validation of the product," says Emanuele<br />

Harlow-based Lynar Manufacturing has<br />

replaced an ageing wire eroding machine<br />

with a new Sodick VL600Q from Sodi-Tech<br />

EDM, a move that has seen the company<br />

double its cutting speed, while<br />

simultaneously reducing wire consumption.<br />

The machine has been set to work<br />

producing press tools for lighting assembly<br />

brackets and other parts used on automotive<br />

trailers.<br />

Lynar Manufacturing is a 10-employee,<br />

family-run business with a turnover in the<br />

region of £1.8 million. The company<br />

specialises in metal pressings, sheet metal<br />

assembly and finishing operations,<br />

predominantly for brackets and metal parts<br />

used in lighting circuits found on<br />

automotive trailers, everything from large<br />

Astolfi, Manager at Alumat.<br />

From planning to completion, a tool will<br />

undergo up to 15 production steps that we<br />

currently realise in about six days This took<br />

us as many as 15 days some ten years ago.”<br />

This improvement required the deliberate<br />

use of machining centres and the attempt to<br />

optimise all processes. The company looked<br />

for systems that would avoid any down time<br />

and facilitate machine-integrated quality<br />

control. In addition, the systems had to allow<br />

direct access during each production phase,<br />

in order to correct any deviations<br />

immediately. Then, six years ago, Alumat<br />

decided to confide in the technology and<br />

professionalism of Blum Novotest. Since<br />

then, the machining centres have been<br />

equipped with BLUM systems that both<br />

check workpiece position, dimensions and<br />

also monitor the tools. These instruments<br />

soon facilitated the achievement of the<br />

desired quality level while delivering<br />

reduced lead-times.<br />

Today all operations of the company use<br />

the Blum LaserControl system for contactless<br />

measuring and monitoring of the cutting<br />

tools. In many machine tools, the Z-MT Type<br />

tool setting probes ensure the high level of<br />

production quality.<br />

“The Blum-Novotest products have<br />

definitely proven themselves in recent years.<br />

This is why we decided to gradually replace<br />

the systems from other manufactures. Our<br />

Blum measuring technology facilitates<br />

precise, reliable and competitive production.<br />

The customer service provided to us by the<br />

Italian branch of the German metrology<br />

specialist also played a decisive part. The<br />

reaction time of the experts employed at<br />

Blum is extremely short and very<br />

supportive,” concludes Mr Astolfi.<br />

Tel: 01283 569691<br />

Email: david@blum-novotest.co.uk<br />

Web: www.blum-novotest.com<br />

UPDATED POWER<br />

PACK AVAILABLE<br />

FROM ENGIS UK<br />

Engis UK, specialist in superabrasive<br />

finishing systems, is offering customers the<br />

updated Power Pack for the Minimo Power<br />

Tooling System.<br />

The Minimo system offers toolmakers,<br />

mold and die finishing specialists and<br />

component manufacturers the most complete<br />

tooling system in the industry, including a<br />

range of interchangeable heads and motors<br />

designed for a wide range of applications<br />

including grinding, deburring and polishing.<br />

Furthermore, Minimo tools are<br />

ergonomically designed to be comfortable,<br />

easy-to-use and produce minimum fatigue.<br />

The updated, high-end power pack<br />

incorporates several new functions for<br />

maximising the performance of hand-pieces,<br />

including the ability to identify the type of<br />

hand-piece that is connected, display rotation<br />

speed, output rate, and control optimum<br />

torque and is also compatible with the earlier<br />

hand-pieces which do not have the motor<br />

identification chip.<br />

Other features of the power pack include<br />

an audible alert function, soft start and rapid<br />

brake mechanism, Quadplex safety system, a<br />

rotation switch convenient carrying handle<br />

and removable power cord.<br />

Tel: 01491 411117<br />

Email: sales@engis.uk.com<br />

Web: www.engis.com<br />

LATEST SODICK EDM DOUBLES CUTTING SPEEDS AT LYNAR<br />

articulated lorries down to 7.5 tonne trucks.<br />

Established for over 40 years, Lynar says it<br />

was one of the first companies in the UK to<br />

introduce wire eroding technology, and it<br />

continues to be recognised as a specialist in<br />

the field.<br />

The Sodick VL series is an economical<br />

line of performance wire EDMs with linear<br />

motor technology that builds on the<br />

technologies of the VZ and SL series. The<br />

medium sized VL600Q is well-suited to a<br />

wide range of machining applications with<br />

its 600 x 400 x 270mm of travel in the X, Y<br />

and Z axes respectively, as well as 80 x 80<br />

mm in the U and V axes.<br />

Tel: 02476511677<br />

Email: sales@sodi-techedm.co.uk<br />

Web: www.sodi-techedm.co.uk<br />

16 <strong>Machinery</strong> <strong>World</strong>, <strong>September</strong> <strong>2016</strong>

WHY HAINBUCH?<br />

igus ® the-chain ... moving energy made easy ...<br />

Robot e-chains®<br />

– easy to open<br />

TESTit clamping force gauge<br />

Clamping force measurement for O.D. and I.D clamping<br />

Can be used rotating [under RPM] and for stationary<br />

applications<br />

Data transmission via bluetooth<br />

Ideal for maintenance, service and process transparency<br />

Software for visualization and archiving<br />

Learn more at<br />

www.hainbuch.com<br />

<br />

<br />

Also available as a completely harnessed system,<br />

including cables with 36 month guarantee<br />

triflex ®<br />

TRCF for maximum<br />

system reliability<br />

● 3-chamber system for large hoses and cables<br />

● Easy to open using a screwdriver<br />

● Easy to lengthen and shorten<br />

● Now 25% more push-pull strength<br />

● Available in sizes 65, 85, 100 Ø<br />

Video at igus.co.uk/triflexTRCF<br />

plastics for longer life ®<br />

igus ®<br />

Caswell Road Northampton NN4 7PW<br />

Tel 01604 677240 Fax 01604 677242 sales@igus.co.uk<br />

<strong>Machinery</strong> <strong>World</strong>, <strong>September</strong> <strong>2016</strong> 17

USED RIVETING MACHINE FROM<br />

THE MARKET LEADERS<br />

❋ MOST TYPES AVAILABLE<br />

❋ FULLY CHECKED<br />

❋ TOOLING<br />

❋ FIXTURING<br />

❋ GENERAL ADVICE<br />

❋ THOUSANDS OF MACHINES SOLD DURING<br />

OUR TWENTY FIVE YEARS IN BUSINESS<br />

CONTACT BILL CHALLENOR<br />

54 Coventry Road, Pailton,<br />

Rugby, Warwickshire CV23 0QB<br />

Tel: (01788) 833301 Fax: (01788) 833481<br />

Email: wgcrivet@gmail com<br />

Web Site: www.wgchallenor.co.uk<br />

Unit 5 Russel House, Molesey Road,<br />

Walton-on-Thames, Surrey KT12 3PE<br />

Tel: 0208 339 7370<br />

Fax: 0208 339 7371<br />

Email: sales@blackfast.com<br />

Web:<br />

www.blackfast.com<br />

ON-LINE<br />

www.machineryworld-online.com<br />

18 <strong>Machinery</strong> <strong>World</strong>, <strong>September</strong> <strong>2016</strong>

For all your vibratory finishing equipment<br />

and materials<br />

• New and used vibratory finishing machines and systems<br />

from 2 litres to 4000 litres<br />

• Finishing media; Ceramic, Plastic, Wood, Steel and Maizorb<br />

• Liquid/powdered/paste compounds<br />

• Abrasive finishing wheels<br />

• Vibratory separators/sieving machines and re-meshing service<br />

• Repairs and relines<br />

• Effluent water treatment systems<br />

• Subcontract finishing and industrial sieving Services<br />

• Redundant machines purchased<br />

• Consultancy<br />

40<br />

1976-<strong>2016</strong><br />

years<br />

in component surface finishing<br />

EuroBLECH <strong>2016</strong><br />

<br />

<br />

<br />

Sharmic for fast, friendly service<br />

Experienced Engineers • After sales technical support • Nationwide deliveries<br />

Sharmic Engineering Ltd<br />

Tel: +44 (0)1299 822135/878123/4/5<br />

Email: info@sharmic.co.uk<br />

www.sharmic.co.uk<br />

<br />

<br />

Traditional wide belt machines<br />

from 600 - 1500mm working widths<br />

The only machines to work simultaneously<br />

on top and bottom<br />

Newly designed dedicated machines for deburring,<br />

corner rounding and oxide removal<br />

Narrow belt throughfeed<br />

machines 150-300mm wide<br />

24 <br />

<br />

Bench top belt grinders<br />

Single belt finishing<br />

machines<br />

Plasma cut blank<br />

deburring machines<br />

For the<br />

Largest range of<br />

ABRASIVE GRINDING,<br />

DEBURRING AND<br />

POLISHING MACHINES<br />

IN THE UK<br />

CLICK ON<br />

www.surtech.co.uk<br />

or ring<br />

0121 359 4322<br />

Portable abrasive wheel<br />

power tools<br />

Portable belt files and<br />

tube finishing tools<br />

Belt grinders<br />

Sheet metal, Tube, Sections Handling Forming<br />

Separation, Cutting Joining, Welding R&D<br />

Finished products, Parts, Assemblies Tools, Dies<br />

Flexible sheet metal working Machine elements<br />

Tube/Section working Additive Manufacturing<br />

Surface treatment Composites Safety at work<br />

Data capture/processing CAD/CAM/CIM systems<br />

Controlling, Regulating, Measuring, Inspection<br />

Factory and warehouse equipment<br />

Dust extractors<br />

Dry and wet<br />

Portable and automatic<br />

bevelling machines<br />

Straight and bent tube<br />

polishing machines<br />

Weld Cleaning tools<br />

Multi-purpose<br />

belt grinders<br />

<br />

HANOVER, GERMANY<br />

www.euroblech.com<br />

Pneumatic, expanding &<br />

standard contact wheels<br />

Polishing mops<br />

and compo<br />

Graining, finishing and<br />

polishing wheels<br />

Narrow and wide abrasive belts for all applications<br />

Surface Technology Products Ltd 244 Heneage Street, Birmingham B7 4LY Email: a.lehnen@surtech.co.uk<br />

Organisers: Mack Brooks Exhibitions Ltd<br />

<strong>Machinery</strong> <strong>World</strong>, <strong>September</strong> <strong>2016</strong> 19

GAUGES LTD<br />

PENICO ROTARY<br />

GRINDING TABLE<br />

• Converts surface grinders<br />

to rotary work<br />

• Robust construction<br />

For further details contact<br />

Penico Gauges Ltd<br />

Tel: 01274 511044<br />

Fax: 01274 510770<br />

Email:<br />

penicogauges@yahoo.co.uk<br />

Web: www.penico.com<br />

Airfield Road, Christchurch, Dorset, BH23 3TG<br />

01202 499 400<br />

general@ellesco.com sales@ellesco.com service@ellesco.com<br />

www.ellesco.co.uk<br />

With One Simple Operation On The Timesavers<br />

Through-Feed Machines You Can:<br />

• Deburr<br />

• Edge Finish and Radius -<br />

Even On Complex Forms & Holes<br />

• Graining/Surface Finishing<br />

Join us at our<br />

OPEN HOUSE<br />

20th-22nd <strong>September</strong><br />

Benefits:<br />

• Consistent Finishing Every Time<br />

• Improved Component Quality<br />

• Improved Productivity & Efficiency<br />

• Reduce Health & Safety Risks

PRECISION SPINDLE<br />

REBUILDING<br />

We offer a complete rebuild service of CNC<br />

machining centre spindles, CNC lathe heads,<br />

Grinding spindles (both belt driven & high<br />

frequency types), Tailstocks, Fine boring<br />

spindles, Milling spindles, Centre-less<br />

grinding spindles, workheads, wheelheads etc.<br />

TECHNOVA PRECISION LTD<br />

Tel: 02476 366503 • Fax: 02476 361979<br />

Web: technovaprecision.com • Email: will@technovaprecision.com<br />

TINBASHERS<br />

USED ROLLFORMERS,<br />

DECOILERS, LEVELLERS,<br />

CUT TO LENGTH AND<br />

SLITTING LINES<br />

FOR SALE OR WANTED<br />

CONTACT TOMMY SHEEHAN<br />

0789 984 7925 or 0161 429 8710<br />

Email: sales@tinbashers.com<br />

Is this the fastest ever,<br />

most productive<br />

automatic CNC machine<br />

for drilling, milling<br />

and scribing beams,<br />

channels and flats?<br />

Don’t just take our word for it...<br />

Robert Savage, Director, G R Contracts<br />

“ We are seeing an overall 50-60% increase in<br />

piece productivity from our new Endeavour.”<br />

Andrew Hirst, Barrett<br />

Steel, Managing Director<br />

“ Endeavour has been instrumental<br />

in helping us to increase our<br />

processing volumes and to meet<br />

our customers requirements.”<br />

Steve Wickens, Managing<br />

Director Wickens<br />

“Endeavour is the foundation for<br />

our drive to double productivity<br />

throughout the business.”<br />

Tomas Twomey, General Manager, IPW Fabricators<br />

“ The ability of the new Endeavour to drill, cut out slots and notches<br />

and produce parts from 76x38 channel right up to 610 Beams<br />

and large section plates up to 60mm thick is truly impressive.”<br />

Chris Scott, Director,<br />

Hescott Engineering<br />

“ With its power and innovative<br />

features, the new Endeavour<br />

line has been a game changer<br />

for us in terms of capacity.”<br />

Courtney Bell, AJN,<br />

Finance Director<br />

“ The Endeavour proved to<br />

be the ultimate solution<br />

for drilling and we have now<br />

purchased 3 of these<br />

impressive machines.”<br />

Enough said...?<br />

For more information on this most innovative CNC drilling, milling and<br />

marking line - featuring 3 new direct drives, 31kw 5,000 rpm spindles<br />

with additional auxiliary axis movement, high speed positioning,<br />

4 sides scribing and hard stamping marking unit - call 01924 223530<br />

or e-mail info@ficep.co.uk<br />

THINK STEEL<br />

FICEP UK Ltd., 3 Gilcar Way, Valencia Park, Wakefield Europort,<br />

Normanton WF10 5QS, UK. www.ficep.co.uk<br />

<strong>Machinery</strong> <strong>World</strong>, <strong>September</strong> <strong>2016</strong> 21

The impact that the right CAM software can<br />

have on a machining business should not be<br />

underestimated, as AI-Met, which is based<br />

near Cardiff, can verify. Here, five-axis milling<br />

and turning, in combination with Edgecam<br />

software from Vero Software, are helping this<br />

oil and gas specialist diversify into the nuclear<br />

market.<br />

“Our craftsmen have been comfortable for<br />

many years running parts through four or five<br />

operations, and it took a while for them to be<br />

fully confident with switching to the Mori<br />

Seiki MTX 2000 five-axis machining centre<br />

and doing everything in one set-up with<br />

Edgecam,” says managing director Phil<br />

Harmer. “However, one particular job that<br />

used to take four or five days is now fully<br />

processed in just under two hours. It’s a<br />

massive time saving, and means we’ll be<br />

looking at increasing our five-axis capability<br />

in the near future.”<br />

Of course, to ensure competitive gain is<br />

maximised, machine shops must keep an eye<br />

on the latest CAM software developments.<br />

Each year, the major players release updated<br />

versions of their CAM suites, all featuring<br />

enhancements designed to simplify the life of<br />

production engineers. For instance, Open<br />

Mind Technologies has recently launched its<br />

HyperMill <strong>2016</strong>.2 CAM software with a host<br />

of enhancements in 2D, 3D, five-axis and HPC<br />

machining that are designed to boost<br />

performance and ease of use.<br />

The HyperMill Maxx Machining HPC<br />

package has once again been expanded to<br />

incorporate five-axis tangent machining of<br />

any arbitrary faces with conical barrel cutters.<br />

The use of conical barrel cutters is said to<br />

enable performance increases of up to 90%<br />

compared with conventional production<br />

methods.<br />

A further enhancement in HyperMill is the<br />

five-axis rest material roughing module. This<br />

has been designed to create high speed,<br />

optimised toolpaths for rest machining from a<br />

previous roughing operation. The definition<br />

of the tilt angles for the B and C axes are<br />

straightforward: the user can choose whether<br />

to automatically create the tilt angle in 3D<br />

mode within a specified angular range, or<br />

generate it from the normal planes.<br />

Elsewhere, 3D Systems has introduced<br />

GibbsCAM <strong>2016</strong>, which is available in the UK<br />

from Tech CADCAM. Building on the<br />

‘Universal Kinematic Machine’ (UKM)<br />

technology of the previous edition,<br />

GibbsCAM <strong>2016</strong> is compatible with a range of<br />

operations, including solid modelling, high<br />

speed machining, two- to five-axis milling,<br />

multi-task machining and wire EDM.<br />

Newly developed features and functions<br />

of GibbsCAM <strong>2016</strong> include enhanced thread<br />

milling (including support for multi-point<br />

tools), tapered threads for both single- and<br />

multi-point tools, and improved simulation.<br />

In addition, the latest VoluMill technology<br />

provides additional toolpath strategies<br />

designed to optimise high speed roughing of<br />

CADCAM & CONTROLS<br />

SOFT SPOT FOR SOFTWARE<br />

large pockets and slots, while open face<br />

milling strategies are introduced that are said<br />

to decrease cutting time by up to 60%.<br />

Similarly, NCG CAM Solutions’ latest<br />

version (v15.0) of its NCG CAM software<br />

includes a number of new features, including<br />

additional functionality to UV passes, tool<br />

sheets, five-axis roughing, the use of T-slot<br />

cutters in five-axis applications, as well as new<br />

user interface features and enhancements.<br />

So, what are the major trends in this<br />

technology area? What is driving<br />

development? Well, the move towards<br />

Industry 4.0, which in effect represents a<br />

connected world of automation and data<br />

exchange in manufacturing technologies, is<br />

certainly having a major effect.<br />

For instance, in a direct move towards<br />

Industry 4.0, Lantek is planning the launch of<br />

a Lantek Expert native version in 64 bit. This<br />

will be a specific version of the software so<br />

that its customers can benefit from the highest<br />

performance offered by current servers and<br />

equipment and, along with the version for 32<br />

bit, will be included in the launch of the 2017<br />

global release. Among other advances, the 64-<br />

bit version is estimated to deliver an<br />

improvement of up to 50% in the speed of<br />

some calculation processes.<br />

Lantek Expert for 64 bit will be able to use<br />

far greater memory volume and do so more<br />

efficiently. The company’s intention is that the<br />

64-bit version is implemented seamlessly, but<br />

at the customer’s discretion, in its 2017<br />

version. At a future point, the 32-bit variant<br />

will disappear and the version for 64 bit will<br />

become standard.<br />

The latest version of TISIS software from<br />

sliding head lathe specialist Tornos, is also<br />

geared towards a future where Industry 4.0<br />

figures heavily. TISIS is offered as an option<br />

that not only allows Tornos machines to be<br />

programmed, but permits interaction using a<br />

tablet computer or smartphone. Of course, to<br />

be able to link the world of production with<br />

the current concepts of Industry 4.0, the<br />

machines must be equipped with more<br />

intelligence. Against this background, Tornos<br />

machines have an industrial PC that serves<br />

both as a data server and storage server.<br />

TISIS is offered in several versions. The<br />

light version allows programming while the<br />

comprehensive version includes<br />

programming, set-up and data management<br />

support functions, as well as an optional<br />

CADCAM system. Furthermore, the<br />

company’s Connectivity Pack enables<br />

production tracking via TISIS Tab (mobile<br />

version for Android and Apple peripherals)<br />

and includes the optional TISIS i4.0<br />

production tracking function and set-up<br />

support via a camera system. The efficiency of<br />

each machine and of the entire workshop is<br />

available upon request. This can be viewed by<br />

machine or machine group, or by time<br />

parameters.<br />

Ultimately, the advantages achieved by a<br />

turn towards connectivity and digitalisation<br />

through Industry 4.0 are flexibility of<br />

production and the potential ‘mass<br />

customisation’ of products. However, this<br />

requires investment in suitable faciliating<br />

technologies such as CAM software and<br />

controls. Those planning an investment in this<br />

area in the near future are advised to choose<br />

carefully – the future could depend on it.<br />

22 <strong>Machinery</strong> <strong>World</strong>, <strong>September</strong> <strong>2016</strong>

core<br />

<br />

Scheduling WIP Tracking SFDC Machine Monitoring Performance Analysis DNC<br />

01273 666999<br />

sales@seikisystems.co.uk<br />

Stay connected:

CADCAM & CONTROLS<br />

hyperMILL ® WITH GREATER PERFORMANCE AND EASE OF USE<br />

OPEN MIND Technologies, one of the leading<br />

manufacturers of CAD/CAM solutions now<br />

introduces hyperMILL® <strong>2016</strong>.2 with a host of<br />

enhancements in 2D, 3D, 5-axis and HPC<br />

machining that will boost performance and ease<br />

of use. Highlights of the new version include 5-<br />

axis tangent machining from the hyperMILL®<br />

MAXX Machining HPC package and also the 5-<br />

axis optimised rest material roughing module<br />

that ensures extremely short calculation and<br />

processing times. In addition, hyperCAD®-S<br />

the CAD for CAM system has also been<br />

significantly improved.<br />

The hyperMILL® MAXX Machining HPC<br />

package has been expanded to incorporate 5-<br />

axis tangent machining of any arbitrary faces<br />

with conical barrel cutters. Delivering results<br />

with speed, the use of conical barrel cutters<br />

enable performance increases of up to 90<br />

percent compared to conventional production<br />

methods. This special feature of the OPEN<br />

MIND enhancement is the application of barrel<br />

cutting tools that have radii of up to 1000mm on<br />

the side of the tool. This unique tool feature<br />

allows the tool to conduct greater step-over<br />

distances that reduce tool paths whilst<br />

improving the theoretical roughness. The result<br />

is extremely fast production times with<br />

optimum surface quality. In addition to this<br />

module, the hyperMILL® MAXX Machining<br />

package includes powerful solutions for<br />

roughing and drilling.<br />

New strategies for 5-axis machining can<br />

speed up production and save tool life and<br />

machine service life. The conical interpolation<br />

results with the "Fast movement optimised" tool<br />

positions on conical way around the pole. So<br />

simultaneous 5-axis movement is generated<br />

with less acceleration of machine axes.<br />

The 5-axis Optimized Rest Roughing creates<br />

high-speed cutting (HSC) optimised tool paths<br />

for the rest machining from a previous<br />

roughing operation. The definition of the tilt<br />

angles for the B- and C-axes are very simple.<br />

The user can choose whether to automatically<br />

create the tilt angle in the '3D mode' within a<br />

specified angular range or generate it from the<br />

normal planes. All connecting paths between<br />

the tilt angles are optimised and fully checked<br />

for collisions. This indexed machining strategy<br />

offers many advantages. Firstly, shorter tools<br />

improve stability and performance. In<br />

particular, deep cavities and hard-to-reach<br />

areas can be processed economically with this<br />

cycle.<br />

OPEN MIND has given hyperMILL® <strong>2016</strong>.2<br />

numerous enhancements for 3D operations.<br />

One new feature is the 3D plane level<br />

machining. Toolpaths for finishing levels can be<br />

quickly and easily generated. Three new<br />

functions are available for 3D optimised rest<br />

material roughing: the 'avoid areas' option can<br />

exclude specific areas from processing, the<br />

'undercut optimisation' feature avoids<br />

unnecessary redundant movements in undercut<br />

areas when performing multi-axis machining<br />

on stock; and the 'plane level detection' is used<br />

when plane level needs to be machined using a<br />

different step-down, an intermediate step is<br />

added automatically.<br />

In hyperCAD®-S, plane curves or texts can<br />

now be created without distorting the geometry<br />

angle on a cylindrical surface or rotational faces.<br />

The direction, scaling and mirroring can also be<br />

modified.<br />

With the function 'Compare and merge'<br />

users can compare revisions of CAD models<br />

and select the geometry elements to insert them<br />

into an existing document. All not-modified<br />

geometries remain in hyperMILL®. So, only the<br />

updated fields have to be reprogrammed. For<br />

the user, the work will be accelerated<br />

considerably.<br />

Tel: 01869 290003 Mob: 07867 971519<br />

Email: adrian.smith@openmind-tech.com<br />

Web: www.openmind-tech.com<br />

CT PRODUCTION RE-SELECTS 123 INSIGHT AFTER SELECTED<br />

SYSTEM FAILS, REAPING BENEFITS<br />

CT Production Ltd, based in Poole, Dorset<br />

provide electronic manufacturing services.<br />

Originally founded in 1982, current MD Mario<br />

Morilla took over the company in 2015 after the<br />

previous owner retired. The company relied on<br />

an MRP package that had limited capabilities,<br />

as Mario explained; "Although we had<br />

reasonable control of our stock there was no<br />

serial number tracking capability and we<br />

couldn't take data out of the system and<br />

manipulate it. We were also looking to enter the<br />

aerospace and military markets, so CRM was an<br />

important factor to assist with managing<br />

ISO9001, SC21 and AS9100 accreditations."<br />

They decided to research the market and<br />

looked at several systems that offered a<br />

combined MRP/CRM solution. The short term<br />

aim was to improve traceability of products and<br />

communications, with the long term target of<br />

integrating third party data such as test results<br />

and spectrum analysis into the system so that<br />

QA documentation can be quickly compiled at<br />

the point of shipping.<br />

Several staff attended two of 123 Insight's<br />

Evaluation Workshops in March and May of<br />

2011. Said Mario; "We came away incredibly<br />

positive. However, others, including the then<br />

MD, that attended the second workshop did not<br />

share that view. In the end it was a 3/2 vote for<br />

another system."<br />

It had taken two years to reach a decision on<br />

a solution and they started implementing the<br />

other system in June 2013, however after<br />

purchase it quickly became apparent that it<br />

would not meet their needs.<br />

Four months after selection the company<br />

decided to halt the implementation. Staff<br />

immediately attended 123insight's six days of<br />

no-obligation training on the understanding<br />

that if the system didn't work for them they<br />

could walk away with nothing to pay.<br />

After the training was completed the<br />

decision was made to immediately select<br />

123insight and move ahead with a staged<br />

implementation. Said Mario; "We decided to<br />

start off with sales orders, works orders,<br />

delivery notes and invoices. There were a<br />