review

aS45307enPA

aS45307enPA

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

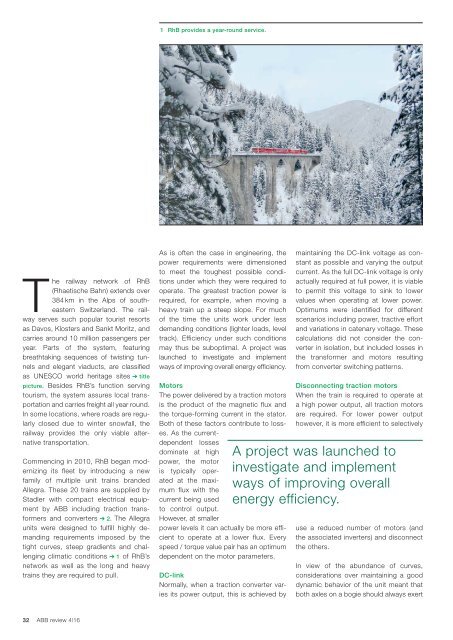

1 RhB provides a year-round service.<br />

© 2016 Eduard Kiener<br />

The railway network of RhB<br />

(Rhaetische Bahn) extends over<br />

384 km in the Alps of southeastern<br />

Switzerland. The railway<br />

serves such popular tourist resorts<br />

as Davos, Klosters and Sankt Moritz, and<br />

carries around 10 million passengers per<br />

year. Parts of the system, featuring<br />

breathtaking sequences of twisting tunnels<br />

and elegant viaducts, are classified<br />

as UNESCO world heritage sites ➔ title<br />

picture. Besides RhB’s function serving<br />

tourism, the system assures local transportation<br />

and carries freight all year round.<br />

In some locations, where roads are regularly<br />

closed due to winter snowfall, the<br />

railway provides the only viable alternative<br />

transportation.<br />

Commencing in 2010, RhB began modernizing<br />

its fleet by introducing a new<br />

family of multiple unit trains branded<br />

Allegra. These 20 trains are supplied by<br />

Stadler with compact electrical equipment<br />

by ABB including traction transformers<br />

and converters ➔ 2. The Allegra<br />

units were designed to fulfill highly demanding<br />

requirements imposed by the<br />

tight curves, steep gradients and challenging<br />

climatic conditions ➔ 1 of RhB’s<br />

network as well as the long and heavy<br />

trains they are required to pull.<br />

As is often the case in engineering, the<br />

power requirements were dimensioned<br />

to meet the toughest possible conditions<br />

under which they were required to<br />

operate. The greatest traction power is<br />

required, for example, when moving a<br />

heavy train up a steep slope. For much<br />

of the time the units work under less<br />

demanding conditions (lighter loads, level<br />

track). Efficiency under such conditions<br />

may thus be suboptimal. A project was<br />

launched to investigate and implement<br />

ways of improving overall energy efficiency.<br />

Motors<br />

The power delivered by a traction motors<br />

is the product of the magnetic flux and<br />

the torque-forming current in the stator.<br />

Both of these factors contribute to losses.<br />

As the currentdependent<br />

losses<br />

dominate at high<br />

power, the motor<br />

is typically operated<br />

at the maximum<br />

flux with the<br />

current being used<br />

to control output.<br />

However, at smaller<br />

power levels it can actually be more efficient<br />

to operate at a lower flux. Every<br />

speed / torque value pair has an optimum<br />

dependent on the motor parameters.<br />

DC-link<br />

Normally, when a traction converter varies<br />

its power output, this is achieved by<br />

maintaining the DC-link voltage as constant<br />

as possible and varying the output<br />

current. As the full DC-link voltage is only<br />

actually required at full power, it is viable<br />

to permit this voltage to sink to lower<br />

values when operating at lower power.<br />

Optimums were identified for different<br />

scenarios including power, tractive effort<br />

and variations in catenary voltage. These<br />

calculations did not consider the converter<br />

in isolation, but included losses in<br />

the transformer and motors resulting<br />

from converter switching patterns.<br />

Disconnecting traction motors<br />

When the train is required to operate at<br />

a high power output, all traction motors<br />

are required. For lower power output<br />

however, it is more efficient to selectively<br />

A project was launched to<br />

investigate and implement<br />

ways of improving overall<br />

energy efficiency.<br />

use a reduced number of motors (and<br />

the associated inverters) and disconnect<br />

the others.<br />

In view of the abundance of curves,<br />

considerations over maintaining a good<br />

dynamic behavior of the unit meant that<br />

both axles on a bogie should always exert<br />

32 ABB <strong>review</strong> 4|16