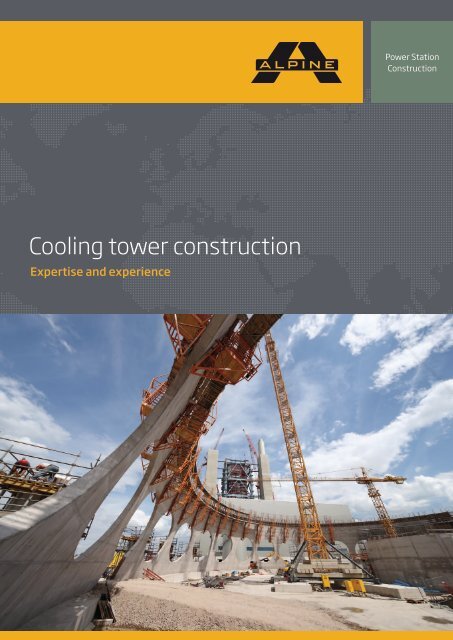

Cooling tower construction

Cooling tower construction

Cooling tower construction

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Cooling</strong> <strong>tower</strong> <strong>construction</strong><br />

Expertise and experience<br />

Power Station<br />

Construction

Power Station<br />

Construction<br />

Visions and Actions –<br />

Shaping the Future Together<br />

With our expertise, we are successfully represented in all<br />

sectors of the <strong>construction</strong> industry, where we are<br />

renowned for our innovative building techniques and<br />

adherence to schedules.<br />

Our portfolio extends from turnkey industrial buildings,<br />

innovative power stations, spectacular cooling <strong>tower</strong>s,<br />

residential and office buildings, and imposing<br />

bridges to modern hydraulic engineering and infrastructure<br />

projects.<br />

We supplement classical <strong>construction</strong> activities with<br />

numerous services, such as planning, structural analysis,<br />

facility management, those of our Mechanical Engineering<br />

Department (MTA) and the Competence Centre for<br />

Construction Material and Concrete Technology.<br />

A high level of quality in the realisation of demanding<br />

<strong>construction</strong> projects is guaranteed by our integrated and<br />

certified management system. Active membership in the<br />

registered association “Ethik Management der Bauwirtschaft”<br />

(ethical management in the <strong>construction</strong><br />

industry) demonstrates ALPINE‘s value-based approach to<br />

management. With our comprehensive safety criteria<br />

we aim for the highest standards of health and safety in all<br />

areas of <strong>construction</strong> activity. As a responsible company<br />

the protection of the environment is an integral part of our<br />

corporate culture and an essential aspect of daily activities.<br />

Our strength lies in our flexibility in implementing complex<br />

requirements. This applies to projects of all sizes. Every day<br />

our employees take the great responsibility of successfully<br />

realising your <strong>construction</strong> projects.

ADDITIONAL REFERENCE PROJECTS<br />

Grafenrheinfeld<br />

> Fuel element container storage<br />

> <strong>Cooling</strong> <strong>tower</strong> refurbishment<br />

Essenbach<br />

> Emergency diesel-power building<br />

> Blowdown cooler<br />

Knapsack<br />

> Cell cooler<br />

Hamm<br />

> Coal-fired power plant<br />

Datteln<br />

> Datteln 4 power station<br />

Hamm-Uentrop<br />

> Gas and thermal power station<br />

Eemshaven (Netherlands)<br />

> Coal-fired power station<br />

Hybrid cooling <strong>tower</strong>,<br />

Hamburg-Moorburg / DE<br />

Constr. period: 11.2010 – 08.2012<br />

Order value: approx. € 36 million *<br />

04<br />

Fan assisted natural<br />

draught cooling <strong>tower</strong>,<br />

Karlsruhe / DE<br />

Constr. period: 05.2009 – 05.2011<br />

Order value: approx. € 19 million *<br />

05<br />

Natural draught cooling<br />

<strong>tower</strong>s, Neurath / DE<br />

Constr. period: 01.2006 – 12.2008<br />

Order value: approx. € 38 million *<br />

06<br />

Mechanical draught<br />

cooling <strong>tower</strong>, Essenbach-<br />

Landshut / DE<br />

Constr. period: 07.2008 – 03.2009<br />

07<br />

* Total for <strong>construction</strong> and planning services<br />

<strong>Cooling</strong> innovations<br />

With the development of special <strong>construction</strong> methods, ALPINE has a<br />

clear technological advantage in all types of cooling <strong>tower</strong>. ALPINE can<br />

produce references ranging from hybrid cooling <strong>tower</strong>s, fan assisted<br />

natural draught cooling <strong>tower</strong> and natural draught cooling <strong>tower</strong>s to the<br />

latest generation of cell coolers.<br />

A 20 - 40% reduction in the <strong>construction</strong> period thanks to ALPINE’s<br />

expertise and professionalism in areas extending from planning and work<br />

preparation to <strong>construction</strong>, in conjunction with increased occupational<br />

safety, distinguishes our innovative special solutions.<br />

InnovatIve clImbIng scaffold<br />

Climbing operations take place in cycles corresponding to the concreting<br />

operations in rings approx. 120 cm high. Tower climbing is automated by<br />

means of hydraulic cylinders, whereby the telescopic working platforms<br />

adapt to the hyperbolic shape of the cooling <strong>tower</strong>.<br />

For its work in developing the climbing scaffold, ALPINE has been distinguished<br />

with such prizes as the FCC Innovation Award.<br />

acId-resIstant hIgh-performance concrete<br />

Depending on requirements, a special high-performance concrete - developed<br />

and optimised by ALPINE and featuring a new mixing technique<br />

- is used, rendering costly internal coating of the cooling <strong>tower</strong> shells<br />

superfluous. This provides a time saving of six months in <strong>construction</strong>.<br />

Because of this concrete, there is no need for recoating the inside of the<br />

cooling <strong>tower</strong> every 15 years, a process that would otherwise require a<br />

six month operational shutdown.<br />

Naturally, the special solutions developed by ALPINE also allow coating<br />

systems to be employed on request.<br />

everythIng from a sIngle source<br />

ALPINE handles the entire project management of challenging cooling<br />

<strong>tower</strong> projects. Our specialists in the technical departments of<br />

the Engineering Office, Work Preparation, the Competence Centre for<br />

Construction Material and Concrete Technology, Surveying, the Mechanical<br />

Engineering Department and, not least, <strong>construction</strong> itself ensure<br />

successful completion of building works in accordance with the highest<br />

quality standards and to the total satisfaction of our customers.<br />

Additional information and further<br />

reference projects can be found on<br />

our website.<br />

www.alpine-bau.de

04<br />

Power Station Construction<br />

Hybrid cooling <strong>tower</strong><br />

Hamburg-Moorburg<br />

A coal-fired power plant is being built<br />

in Moorburg with a hybrid cooling<br />

<strong>tower</strong>. Special requirements for the<br />

overall height and block operation of<br />

the cooling <strong>tower</strong> represented the<br />

major challenges in the planning phase.<br />

Together with our consortium partner<br />

Hamon Thermal Germany GmbH, we<br />

implemented the customer’s requirements<br />

during the planning phase.<br />

During <strong>construction</strong>, the building<br />

technique developed by ALPINE featuring<br />

the ALPINE scaffolding proved to be<br />

the ideal solution, particularly due to<br />

the very cramped working conditions.<br />

For the formation of the openings<br />

in the wet and dry part, ALPINE has<br />

developed technical solutions for<br />

operational optimisation and observing<br />

general safety conditions, for which<br />

a patent is pending to protect the<br />

company’s intellectual property rights.<br />

ALPINE develops cost-effective <strong>construction</strong><br />

methods that ensure completion deadlines.<br />

FEATURES<br />

Optimisation of pile foundations<br />

36 round fan openings approx. 8.70 m in diameter<br />

36 rectangular openings (approx. 9.50 x 8.75 m) in the dry part of the<br />

cooling <strong>tower</strong> shell<br />

HYBRID COOLING TOWER<br />

HAMBURG / GERMANY<br />

Planning and <strong>construction</strong> output:<br />

earthworks, special foundations, steel<br />

<strong>construction</strong> and reinforced concrete<br />

work<br />

Height: 60 m<br />

Constr. period: 11.2010 – 08.2012<br />

Order value: approx. € 36 million<br />

(<strong>construction</strong>)

Fan assisted natural draught<br />

cooling <strong>tower</strong> Karlsruhe<br />

A circular fan assisted natural draught<br />

cooling <strong>tower</strong> was erected at the RDK8<br />

coal-fired power station in Karlsruhe.<br />

The unique <strong>construction</strong> was planned<br />

and built with the ALPINE climbing<br />

scaffold and the associated shell<br />

system. Development of the building<br />

enabled the fulfilment of the strict<br />

tolerance requirements in conjunction<br />

with the very tight <strong>construction</strong> period.<br />

The so-called “combi-structure” was<br />

erected in the centre of the cooling<br />

<strong>tower</strong>. This facilitates switching between<br />

different operating modes from<br />

through-flow to outflow operation.<br />

ALPINE finds cost-effective solutions for<br />

its clients.<br />

FEATURES<br />

Foundations with vibro-compaction columns<br />

28 round openings in the cooling <strong>tower</strong> shell with a diameter of approx. 7.20 m<br />

Combi-structure for switching between different operating modes<br />

Planning in collaboration with Hamon Thermal Germany GmbH<br />

Power Station Construction<br />

FAN ASSISTED NATURAL<br />

DRAUGHT COOLING TOWER<br />

KARLSRUHE / GERMANY<br />

Planning and <strong>construction</strong> output:<br />

earthworks, special foundations, steel<br />

<strong>construction</strong> and reinforced concrete<br />

work<br />

Height: 80 m<br />

Constr. period: 05.2009 – 05.2011<br />

Order value: approx. € 19 million<br />

(<strong>construction</strong>)<br />

05

06<br />

Power Station Construction<br />

Natural draught cooling<br />

<strong>tower</strong>s Neurath<br />

Two cooling <strong>tower</strong>s were erected for<br />

the new lignite-optimised power plants<br />

F and G in Grevenbroich, in the immediate<br />

vicinity of Neurath power station.<br />

Their state-of-the-art design represented<br />

a completely new technical<br />

challenge. The climbing scaffold<br />

developed especially for this purpose<br />

adapts automatically to the <strong>construction</strong><br />

progress and shape of the cooling<br />

<strong>tower</strong>. With the development and<br />

optimisation of a special acid-resistant,<br />

high-performance concrete, ALPINE<br />

demonstrated its technological<br />

expertise in modern power station<br />

<strong>construction</strong>.<br />

ALPINE innovations shorten the <strong>construction</strong><br />

period and increase the level of safety for<br />

workers.<br />

FEATURES<br />

Acid-resistant concrete of cooling <strong>tower</strong> shells and trickle grates<br />

Use of the ALPINE scaffolding for creating cooling <strong>tower</strong> shells<br />

NAT. DRAUGHT COOLING TOWERS<br />

NEURATH / GERMANY<br />

Planning and <strong>construction</strong> output:<br />

erthworks, special foundations, steel<br />

<strong>construction</strong> and reinforced concrete<br />

work<br />

Natural-draught cooling <strong>tower</strong>s:<br />

each 172 m high<br />

Shell surface area: 80,000 m² each<br />

Constr. period: 01.2006 – 12.2008<br />

Order value: approx. € 38 million<br />

(<strong>construction</strong>)

Mechanical draught cooling<br />

<strong>tower</strong> Isar nuclear power<br />

station<br />

In order to increase the cooling capacity,<br />

a new cell and blowdown cooler<br />

was built at the Isar nuclear power<br />

station in the immediate vicinity of the<br />

existing cell cooler. The design selected<br />

by ALPINE, featuring prefabricated<br />

reinforced concrete units and semi-<br />

finished parts, allowed fulfilment of<br />

the exacting requirements made of<br />

the concrete surfaces in the cooling<br />

cells. Building work was completed<br />

successfully not least due to the good,<br />

close collaboration between planning,<br />

<strong>construction</strong> and the client.<br />

ALPINE complete solutions for all<br />

requirements from approval planning to<br />

commissioning from a single source.<br />

FEATURES<br />

Construction of a cell and blowdown cooler under extremely strict<br />

time constraints<br />

Very short planning phase prior to start of <strong>construction</strong><br />

General nuclear legal conditions<br />

Power Station Construction<br />

MECHANICAL DRAUGHT COOLING<br />

TOWER<br />

ESSENBACH-LANDSHUT / DE<br />

Planning and <strong>construction</strong> output:<br />

earthworks, special foundations, steel<br />

<strong>construction</strong> and reinforced concrete<br />

work<br />

Constr. period: 07.2008 – 03.2009<br />

07

ALPINE Bau Deutschland AG · Industrial & Power Station Construction<br />

Kronenburgallee 1 · 44141 Dortmund · Germany · Telephone +49 231 5413-0 · Fax -632<br />

powerstation@alpine-bau.de · www.alpine-bau.de<br />

Subject to changes, printing errors and/or typographical errors. Last updated: 01.2012 / I