Modern Plastics Worldwide - March 2010 - dae uptlax

Modern Plastics Worldwide - March 2010 - dae uptlax

Modern Plastics Worldwide - March 2010 - dae uptlax

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

MODERN EXECUTIVE<br />

was also supported by Focus<br />

on Energy with an incentive<br />

grant of $50/hp replaced, with<br />

an extra $10/hp bonus when<br />

Xten provides savings data.<br />

Right to the bottom line<br />

Xten is also working with<br />

CleanTech Partners, a funding<br />

partner of Focus on Energy,<br />

which has a financing system<br />

for new emerging technologies.<br />

Both the heater bands<br />

and variable drives fell into<br />

the scope of this program,<br />

and Xten received 5% interest<br />

financing, paid no money<br />

down, and pays back the loan<br />

through a 50/50 shared savings<br />

program on the heater bands and a<br />

30/70 split on the VFDs.<br />

“For every dollar we save on the<br />

heater bands, we keep $0.50 and pay<br />

them back $0.50,” explains Davidson.<br />

“That’s money directly to our bottom<br />

Don’t compromise<br />

on quality.<br />

For further information please contact:<br />

info@gabriel-chemie.com<br />

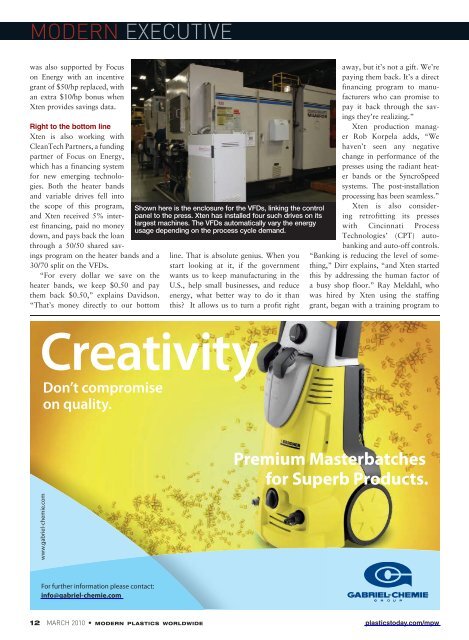

Shown here is the enclosure for the VFDs, linking the control<br />

panel to the press. Xten has installed four such drives on its<br />

largest machines. The VFDs automatically vary the energy<br />

usage depending on the process cycle demand.<br />

line. That is absolute genius. When you<br />

start looking at it, if the government<br />

wants us to keep manufacturing in the<br />

U.S., help small businesses, and reduce<br />

energy, what better way to do it than<br />

this? It allows us to turn a profit right<br />

www.gabriel-chemie.com Creativity<br />

away, but it’s not a gift. We’re<br />

paying them back. It’s a direct<br />

financing program to manufacturers<br />

who can promise to<br />

pay it back through the savings<br />

they’re realizing.”<br />

Xten production manager<br />

Rob Korpela adds, “We<br />

haven’t seen any negative<br />

change in performance of the<br />

presses using the radiant heater<br />

bands or the SyncroSpeed<br />

systems. The post-installation<br />

processing has been seamless.”<br />

Xten is also considering<br />

retrofitting its presses<br />

with Cincinnati Process<br />

Technologies’ (CPT) autobanking<br />

and auto-off controls.<br />

“Banking is reducing the level of something,”<br />

Dirr explains, “and Xten started<br />

this by addressing the human factor of<br />

a busy shop floor.” Ray Meldahl, who<br />

was hired by Xten using the staffing<br />

grant, began with a training program to<br />

Premium Masterbatches<br />

for Superb Products.<br />

12 MARCH <strong>2010</strong> • MODERN PLASTICS WORLDWIDE plasticstoday.com/mpw