The Journal of Australian Ceramics Vol 50 No 2 July 2011

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Focus : <strong>Ceramics</strong> + Util ity<br />

-------<br />

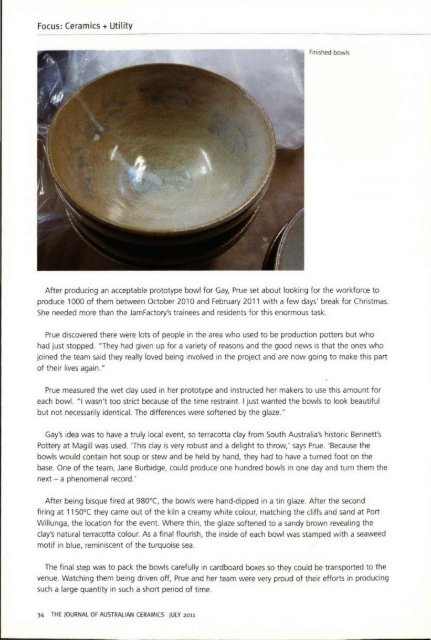

finished bowls<br />

After producing an acceptable prototype bowl for Gay, Prue set about looking for the workforce to<br />

produce 1000 <strong>of</strong> them between October 2010 and February <strong>2011</strong> with a few days' break for (hristmas.<br />

She needed more than the Jam Factory's trainees and residents for this enormous task .<br />

Prue discovered there were lots <strong>of</strong> people in the area who used to be production potters but who<br />

had just stopped. "<strong>The</strong>y had given up for a variety <strong>of</strong> reasons and the good news is that the ones who<br />

joined the team said they really loved being involved in the project and are now going to make this part<br />

<strong>of</strong> their lives again."<br />

Prue measured the wet clay used in her prototype and instructed her makers to use this amount for<br />

each bowl. "I wasn 't too strict because <strong>of</strong> the time restraint. I just wanted the bowls to look beautiful<br />

but not necessarily identical. <strong>The</strong> differences were s<strong>of</strong>tened by the glaze."<br />

Gay's idea was to have a truly local event, so terracotta clay from South Australia 's historic Bennett's<br />

Pottery at Magill was used. 'This clay is very robust and a delight to throw,' says Prue. 'Because the<br />

bowls would contain hot soup or stew and be held by hand, they had to have a turned foot on the<br />

base. One <strong>of</strong> the team, Jane Burbidge, could produce one hundred bowls in one day and turn them the<br />

next - a phenomenal record.'<br />

After being bisque fired at 980 0 (, the bowls were hand-dipped in a tin glaze. After the second<br />

firing at 11<strong>50</strong> 0 ( they came out <strong>of</strong> the kiln a creamy white colour, matching the cliffs and sand at Port<br />

Willunga, the location for the event. Where thin, the glaze s<strong>of</strong>tened to a sandy brown revealing the<br />

clay's natural terracotta colour. As a final flourish, the inside <strong>of</strong> each bowl was stamped with a seaweed<br />

motif in blue, reminiscent <strong>of</strong> the turquoise sea .<br />

<strong>The</strong> final step was to pack the bowls carefully in cardboard boxes so they could be transported to the<br />

venue . Watching them being driven <strong>of</strong>f, Prue and her team were very proud <strong>of</strong> their efforts in producing<br />

such a large quantity in such a short period <strong>of</strong> time.<br />

34 THE JOURNAL Of AUSTRALIAN CERAMICS JULY <strong>2011</strong>