low

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Background<br />

As it was introduced on opening part of this<br />

section, monitoring of IOR/EOR projects<br />

is being considered necessary to guide and<br />

guarantee the success of these projects. In lack of<br />

a proper monitoring program, the fate of injected<br />

material would be unknown with high risk of<br />

injected material (e.g., CO 2<br />

, Methane, Polymer,<br />

Modified water) to be migrated to another layer.<br />

There have recently been introduced variety of<br />

monitoring programs, however, 4D seismic, due<br />

to its full and 3 dimensional coverage of reservoir,<br />

is being considered as the main monitoring<br />

program. Utilising 3D and 4D seismic data,<br />

international oil and gas companies have improved<br />

the reservoir recovery factor in North Sea above<br />

30% and reaching at around 60% [1] . By measuring<br />

the water and gas fronts and pressure variation<br />

in the reservoir as well as by identifying bypassed<br />

oil and gas, it has been successfully used on most<br />

of IOR/EOR projects on the North Sea reservoirs<br />

to optimise IOR/EOR projects, well placement<br />

and production/injection plans. On the other<br />

hand, most of failed injection projects have been<br />

typically suffering from lack of comprehensive<br />

monitoring programs.<br />

What Does Seismic Data Offer to<br />

Us?<br />

Seismic data contains quantitative and valuable<br />

information that has widely been used<br />

during reservoir exploration, development,<br />

production and monitoring steps. Quantitative<br />

seismic interpretation such as rock physics,<br />

AVO modelling, inversion and geomechanics is<br />

normally ended up with extracting reservoir static<br />

parameters such as porosity, shale content and<br />

oil and gas saturation from the seismic data. 4D<br />

seismic, which is a series of repeated 3D seismic<br />

surveys over time, has been extensively used<br />

by oil and gas companies to monitor reservoir<br />

production and injection in time and space. The<br />

elastic and acoustic parameters of fluid and rock<br />

changes by production activities, and this affects<br />

the reflection coefficients at the top as well as at<br />

the base of reservoir. These changes are detected<br />

by amplitude changes in different angles,<br />

timeshift or even frequency-derived attributes<br />

(Figure 1). 4D seismic has the potential to provide<br />

information regarding fluid movements, pressure<br />

changes, reservoir compaction, barriers and<br />

compartments, fault transmissibility and general<br />

connectivity.<br />

These information assist to optimise IOR/<br />

EOR projects in the filed scale, improve well<br />

performance and possibly increase a field’s<br />

economic life. Time lapse seismic applicability has<br />

been proven for monitoring of gas injection for the<br />

storage purposes, water injection and managing<br />

the gas coming out of solution. It has also been<br />

used in monitoring of heavy oil reservoirs, gas<br />

injection and gas reservoir production [3] . Figure<br />

1 shows repeated saturation logs on 1989, 1992,<br />

1993, 1994, 1995 and 1997 on Gullfaks field<br />

(North Sea). It also shows seismic data on 1985<br />

(before production) and 1999 after production<br />

and injection. Utilising Rock Physics analysis, top<br />

of oil bearing sandstone is represented by yel<strong>low</strong><br />

colour on the seismic sections. As it can be seen<br />

from Figure 1, yel<strong>low</strong> colour signal disappears<br />

once it reaches at oil-water contact. OWC<br />

movement can be observed on both well logs<br />

and seismic data that matches with the animated<br />

figures on the right hand side.<br />

The Selected Case Studies<br />

In this brief article, there are presented a few<br />

successful examples from the literature. The<br />

first example (Figure 2) is from North Sea. Halfdan<br />

reservoir is a Carbonate (Chalk) oil reservoir that is<br />

under FAST (Fracture Aligned Sweep Technology)<br />

production method [1] . Horizontal wells produces<br />

for 6 months until it is converted to the water<br />

injection well. Water front is monitored by 4D<br />

seismic data. Water replaced by oil presents<br />

hardening signal (increase in acoustic impedance)<br />

on the 4D seismic maps that is shown by blue<br />

colour on Figure 2-a and b. A highlighted area<br />

is shown on d and e for better visualisations. As<br />

an example, the water front around the injector<br />

well (dashed blue line) is presented on 2005-1992<br />

maps (a and d). Water front movement towards<br />

production wells (green lines) can be detected on<br />

2012 on b and e maps. White colour represents unswept<br />

oil in these figures. Figure 2-c and f shows<br />

2012-2005 to understand the water movement<br />

over time in one map. Red colour signals on these<br />

maps represent the softening signal (decrease in<br />

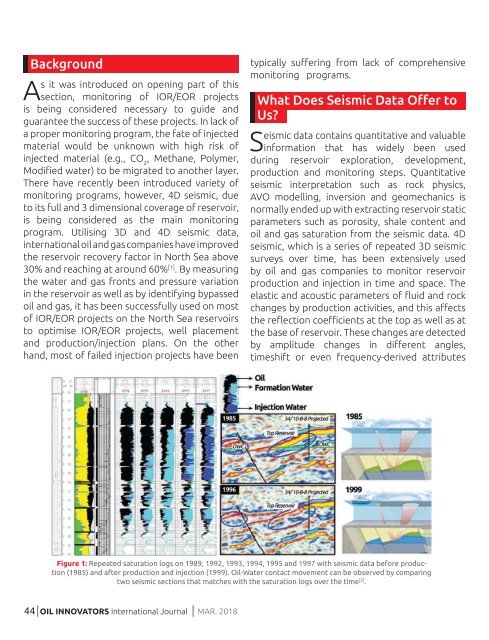

Figure 1: Repeated saturation logs on 1989, 1992, 1993, 1994, 1995 and 1997 with seismic data before production<br />

(1985) and after production and injection (1999). Oil-Water contact movement can be observed by comparing<br />

two seismic sections that matches with the saturation logs over the time [2] .<br />

Figure 2: 4D seismic maps on 2005-1992, 2012-1992 and 2012-2005 on Halfdan oil field. The bottom figure shows<br />

the selected area in detail. Blue colour represents the hardening 4D seismic signal that is due to oil replacing by<br />

water. On the other hand, red colour signal represents the oil replacing by gas due to gas coming out of solution<br />

mainly on the northern parts in which pressure goes be<strong>low</strong> bubble point pressure. Production and injection wells<br />

re shown by green and dashed blue lines [1] .<br />

44 OIL INNOVATORS International Journal MAR. 2018 45