EN | Bale Transport Devices | Goeweil

Bale Transport Devices for round and square bales

Bale Transport Devices for round and square bales

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

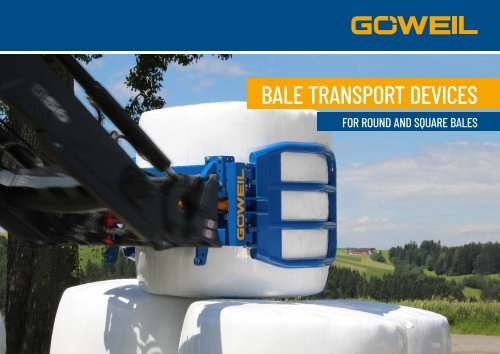

BALE TRANSPORT DEVICES<br />

FOR ROUND AND SQUARE BALES

GÖWEIL<br />

MASCHIN<strong>EN</strong>BAU GMBH<br />

The name Göweil has been synonymous with the highest quality product range in the bale wrapping and baling technology sector since<br />

1988.<br />

Other core areas include the manufacture of bale opening and transport devices, high lift buckets as well as blade sharpeners.<br />

MECHANICAL <strong>EN</strong>GINEERING AT THE<br />

HIGHEST LEVEL<br />

Professional solutions for the agro-industrial sector<br />

As an exceptionally high portion of its products are exported, GÖWEIL machines<br />

have become renowned and are widely used throughout the world.<br />

The company originally specialized in the production of agricultural machines, but<br />

its machines are now also available for industrial use.<br />

GÖWEIL is characterized by the following four values:<br />

QUALITY.<br />

All products are designed, developed<br />

and produced at the company's sites<br />

in Kirchschlag and Rainbach (Upper<br />

Austria).<br />

EFFICI<strong>EN</strong>CY.<br />

By continuously developing our<br />

product range, we offer high-quality<br />

and efficient solutions in keeping with<br />

the times.<br />

KNOW-HOW.<br />

Years of experience, as well as close<br />

cooperation between design and<br />

manufacturing, are the key to our wellthought-out<br />

solutions.<br />

SERVICE.<br />

Even the best machine needs maintenance.<br />

Our service team is available 24<br />

hours a day and will take care of your<br />

request.<br />

Company locations in Kirchschlag (above) and Rainbach (below)<br />

2

OUR SOLUTIONS:<br />

BALE TRANSPORT DEVICES<br />

TDE | <strong>Bale</strong> transport spike single 4<br />

For transporting unwrapped bales<br />

TDD | <strong>Bale</strong> transport spike double 5<br />

For transporting two unwrapped bales<br />

BTGME | Round bale transport fork, mechanical 6 - 7<br />

For transporting wrapped and unwrapped<br />

bales<br />

BTGHA | Round bale transport fork with tipper 8 - 9<br />

For transporting and tipping wrapped and unwrapped bales<br />

DTR | Double transport frame 10 - 11<br />

For attaching two BTGME / BTGHA transport forks<br />

BTGHY | Round bale transport fork, hydraulic 12 - 13<br />

For transporting, loading, and stacking wrapped and unwrapped bales<br />

RBG | Round bale grabber 14 - 15<br />

For transporting, loading, and stacking round bales<br />

BTGQU | Square bale grabber 16 - 17<br />

For transporting and stacking square & round bales<br />

TRANSPORT DEVICE<br />

GFM | Film storage 18 - 19<br />

For transporting up to 16 rolls of film<br />

3

TDE<br />

BALE TRANSPORT SPIKE SINGLE<br />

The transport spike has been specially designed for transporting unwrapped round bales.<br />

The tine protection means that the TDE is also suitable for road transport.<br />

950<br />

690<br />

460<br />

Dimensions in mm<br />

BASIC MODEL<br />

Base frame with Cat. I and II three-point linkage<br />

Euro-attachment<br />

Reinforced tines | Ø: 42 mm, length: 1100 mm<br />

Tine protection for road transport<br />

TECHNICAL DATA<br />

Weight<br />

L x W x H<br />

<strong>Bale</strong> weight<br />

75 kg<br />

1210 x 1080 x 690 mm<br />

max. 1500 kg<br />

ADDITIONAL EQUIPM<strong>EN</strong>T<br />

Support foot<br />

Support foot<br />

POSSIBLE ATTACHM<strong>EN</strong>TS (without installation)<br />

Cat. II Weiste-Triangle adapter<br />

Other attachments - on request<br />

4

TDD<br />

BALE TRANSPORT SPIKE DOUBLE<br />

950<br />

The double transport spike has been developed for transporting two unwrapped round or square bales with a maximum bale diameter of<br />

1.6 m. The tine protection means that the TDD is also suitable for road transport.<br />

610<br />

640<br />

690<br />

Dimensions in mm<br />

610<br />

BASIC MODEL<br />

Base frame with Cat. I and II three-point linkage<br />

Euro-attachment<br />

Reinforced tines | Ø: 42 mm, length: 1100 mm<br />

Tine protection for road transport<br />

TECHNICAL DATA<br />

Weight<br />

L x W x H<br />

<strong>Bale</strong> weight<br />

134 kg<br />

1210 x 2000 x 690 mm<br />

max. 2500 kg<br />

ADDITIONAL EQUIPM<strong>EN</strong>T<br />

Support foot<br />

Square bale attachment<br />

Support foot<br />

Square bale attachment<br />

POSSIBLE ATTACHM<strong>EN</strong>TS (without installation)<br />

Cat. II Weiste-Triangle adapter<br />

Other attachments - on request<br />

5

BTGME<br />

ROUND BALE TRANSPORT FORK, MECHANICAL<br />

1.200<br />

The round bale transport fork is suitable for gently transporting wrapped and unwrapped round bales with a diameter of 1 - 1.8 m. The<br />

opening area can be adjusted mechanically in 50 mm increments using a quick-release fastener. The fork pipes can be turned upward for<br />

road transport.<br />

1.250<br />

850<br />

970<br />

Dimensions in mm<br />

BASIC MODEL<br />

Base frame with Cat. I and II three-point linkage<br />

Large fork pipes / Ø: 110 mm<br />

Quick-release fastener for width adjustment<br />

Quick-release fastener for width adjustment<br />

TECHNICAL DATA<br />

Weight<br />

L x W x H<br />

<strong>Bale</strong> weight<br />

90 kg<br />

1380 x 1140 x 970 mm<br />

max. 1800 kg<br />

6

1 2<br />

IMAGE DESCRIPTION<br />

1) The fork pipes can be turned upward for road transport<br />

2) The BTGME is especially gentle when transporting wrapped bales<br />

3) The transport fork in use with the Cat. II Weiste-Triangle adapter<br />

4) <strong>Bale</strong> pickup with the hydraulic width adjustment<br />

5) The BTGME when loading a wrapping machine<br />

3 4<br />

ADDITIONAL EQUIPM<strong>EN</strong>T<br />

Hydraulic width adjustment<br />

The opening area can be adjusted continuously using two hydraulic cylinders<br />

Double-acting hydraulic connection required<br />

<strong>Bale</strong> transport spike double conversion kit<br />

For transporting two unwrapped round or square bales simultaneously<br />

(max. bale diameter 1.6 m)<br />

Reinforced tines (Ø: 42 mm, length 1100 mm)<br />

Payload: max. 1800 kg<br />

Hydraulic width adjustment<br />

5<br />

<strong>Bale</strong> transport spike double conversion kit<br />

POSSIBLE ATTACHM<strong>EN</strong>TS (without installation)<br />

Cat. II Weiste-Triangle adapter<br />

Other attachments - on request<br />

7

BTGHA<br />

ROUND BALE TRANSPORT FORK WITH TIPPER<br />

1.150<br />

The round bale transport fork has been developed for transporting, and in particular for tipping, wrapped or unwrapped round bales with a<br />

diameter of 1 - 1.8 m. The bales can therefore be transported, deposited, and stored on their ends in an extremely gentle manner. The fork<br />

pipes are unlocked using two hydraulic cylinders.<br />

970<br />

1.250<br />

850<br />

Dimensions in mm<br />

BASIC MODEL<br />

Base frame with Cat. I and II three-point linkage<br />

Large fork pipes / Ø: 110 mm<br />

Mechanically adjustable fork pipes with quick-release fastener<br />

Two hydraulic cylinders for unlocking the fork pipes<br />

Quick-release fastener for width adjustment<br />

TECHNICAL DATA<br />

Weight<br />

L x W x H<br />

<strong>Bale</strong> weight<br />

Max. operating pressure<br />

REQUIRED CONNECTIONS<br />

• Single-acting hydraulic connection<br />

136 kg<br />

1350 x 1140 x 970 mm<br />

max. 1800 kg<br />

200 bar<br />

8

1 2<br />

IMAGE DESCRIPTION<br />

1) Hydraulic cylinders for unlocking<br />

2) Wrapped round bales are picked up gently and transported with ease<br />

3) The fork pipes are unlocked using the hydraulic cylinders<br />

4) The round bales are carefully deposited on their end<br />

5) BTGHA in use in the field with the DTR<br />

3 4<br />

ADDITIONAL EQUIPM<strong>EN</strong>T<br />

Hydraulic width adjustment<br />

The opening area can be adjusted continuously using two hydraulic cylinders<br />

Double-acting hydraulic connection required<br />

5<br />

Hydraulic width adjustment<br />

POSSIBLE ATTACHM<strong>EN</strong>TS (without installation)<br />

Cat. II Weiste-Triangle adapter<br />

Other attachments - on request<br />

9

DTR<br />

DOUBLE TRANSPORT FRAME<br />

1.130<br />

The double transport frame has been designed so that two BTGME or BTGHA round bale transport forks can be attached to the transport<br />

frame in just a few simple steps. This means that two round bales with a diameter of up to 1.6 m can be transported simultaneously.<br />

2.440<br />

Dimensions in mm<br />

450<br />

BASIC MODEL<br />

Base frame with Cat. II three-point linkage<br />

Hydraulically movable transport carriage<br />

WITHOUT BTGME/BTGHA bale transport forks<br />

TECHNICAL DATA<br />

Weight (without bale forks)<br />

L x W x H<br />

<strong>Bale</strong> weight<br />

Max. operating pressure<br />

218 kg<br />

450 x 2440 x 1130 mm<br />

max. 3500 kg<br />

200 bar<br />

REQUIRED CONNECTIONS<br />

• Double-acting hydraulic connection<br />

10

1 2<br />

IMAGE DESCRIPTION<br />

1) Pickup of the first round bale<br />

2) The additional hydraulic units lift the bales by up to 380 mm<br />

3) The second round bale is picked up<br />

4) Two bales are fully loaded<br />

5) Both round bales can be deposited at the storage location simultaneously<br />

6) The double transport frame in use with 2 x BTGHA<br />

3 4<br />

FUNCTIONAL DESCRIPTION<br />

Using the bale fork on which the hydraulically movable transport carriage is mounted, the<br />

first bale is picked up and lifted with the additional hydraulic unit.<br />

(Lifting height: max. 380 mm)<br />

5 6<br />

The second bale can be loaded without having to set down the first bale again. This<br />

prevents damage to the bale.<br />

The additional hydraulic units are lowered again to set down both round bales.<br />

POSSIBLE ATTACHM<strong>EN</strong>TS (without installation)<br />

Cat. II Weiste-Triangle adapter<br />

Other attachments - on request<br />

11

BTGHY<br />

ROUND BALE TRANSPORT FORK, HYDRAULIC<br />

920<br />

The BTGHY has been designed for transporting and stacking wrapped and unwrapped round bales with a diameter of 0.9 - 1.8 m. The hydraulically<br />

actuated rotatable fork pipes guarantee extremely gentle operation without any damage to the bales.<br />

1.670<br />

600 1.220<br />

Dimensions in mm<br />

BASIC MODEL<br />

Base frame with Cat. I and II three-point linkage<br />

Ball bearing mounted, rotatable fork pipes<br />

Hydraulic cylinder for width adjustment<br />

Support foot<br />

TECHNICAL DATA<br />

Weight<br />

L x W x H<br />

<strong>Bale</strong> weight<br />

Max. operating pressure<br />

245 kg<br />

1580 x 1310 x 920 mm<br />

max. 1800 kg<br />

200 bar<br />

REQUIRED CONNECTIONS<br />

• Double-acting hydraulic connection<br />

12

1 2<br />

IMAGE DESCRIPTION<br />

1) Unloading, feeding, and depositing using the front loader<br />

2) Easy loading and unloading of trailers<br />

3) Use in stationary operation with a vehicle<br />

4) The BTGHY is perfectly suited to the stacking of round bales<br />

5) <strong>Transport</strong> fork with the POSSIBLE ATTACHM<strong>EN</strong>TS (without installation) Cat. II Weiste-Triangle<br />

adapter and Euro-attachment<br />

6) Additional equipment: bale transport spike conversion kit<br />

3 4<br />

ADDITIONAL EQUIPM<strong>EN</strong>T<br />

Pressure relief valve incl. check valve<br />

(Required for wheel loaders and telescopic wheel loaders with an operating pressure<br />

above 200 bar)<br />

<strong>Bale</strong> transport spike conversion kit<br />

This conversion kit allows the BTGHY to be converted into a bale transport spike quickly<br />

and easily and is therefore suitable for transporting round and square bales.<br />

With reinforced tines - Ø: 42 mm, length 1100 mm<br />

The tines are screwed on separately and are not attached within the rotary pipes. This<br />

ensures an extremely robust design both for the transport fork and the transport spike.<br />

5 6<br />

POSSIBLE ATTACHM<strong>EN</strong>TS (without installation)<br />

Euro-attachment<br />

Hauer B, Merlo, SMS, MX<br />

Dieci/New Holland, Dieci Dedalus, Amkodor, Manitou, JCB Q-Fit, JCB Compact Tool Carrier,<br />

Weidemann Hydraulik, Kramer, Schäffer up to 3550, Schäffer from 3550T, Atlas,<br />

Claas Scorpion, Zettelmeyer 402, Volvo BM, Hydrema, Faucheux, Bobcat, CAT 907H/Liebherr<br />

L507, CAT TH 407 C, Giant, Skid Steer, Fendt Cargo T955/Sennebogen<br />

Cat. II Weiste-Triangle adapter<br />

Other attachments - on request<br />

13

RBG<br />

ROUND BALE GRABBER<br />

800<br />

RBG 140: 1.360<br />

1.360<br />

The RBG allows for easy loading and stacking of round bales of any type (silage, hay, straw) with a diameter of 1.1 to 1.6 m. The rounded design<br />

ensures an extremely gentle and secure grip. Evenly distributed pressure on the bales means that the film is not overstretched or damaged.<br />

An important feature is also the short, slender design, whereby the center of gravity lies very close to the loader.<br />

1.820<br />

RBG 140: 1.560<br />

100<br />

RBG 140: 40<br />

Dimensions in mm<br />

BASIC MODEL<br />

Base frame with Euro-attachment<br />

Large, rounded gripper arms with swivel compensator<br />

Hydraulic cylinder for bale securing<br />

TECHNICAL DATA<br />

Weight<br />

L x W x H<br />

<strong>Bale</strong> weight<br />

Max. operating pressure<br />

202 kg<br />

1260 x 1360 x 800 mm<br />

max. 1800 kg<br />

200 bar<br />

RBG 140<br />

The RBG 140 bale grabber variant is available for transporting smaller bales<br />

(diameter 0.8 - 1.3 m):<br />

TECHNICAL DATA | RBG 140<br />

Weight<br />

L x W x H<br />

<strong>Bale</strong> weight<br />

Max. operating pressure<br />

199 kg<br />

1130 x 1360 x 800 mm<br />

max. 1800 kg<br />

200 bar<br />

REQUIRED CONNECTIONS<br />

• Double-acting hydraulic connection<br />

14

1 2<br />

IMAGE DESCRIPTION<br />

1) The RBG allows for easy loading and unloading of trailers<br />

2) The RBG is ideal for tipping a bale<br />

3) The RBG in use with a stationary wrapping machine<br />

4) The rounded design allows for extremely gentle stacking of the round bales<br />

5) The short, slender design means that the center of gravity lies very close to the loader<br />

6) The swivel compensator enables extremely gentle adjustment of the gripper arms.<br />

If the bales are not clamped fully in the center at any time, the<br />

gripper arms can align themselves optimally with the bales independently of one another.<br />

This prevents shifting of the<br />

round bale.<br />

3 4<br />

ADDITIONAL EQUIPM<strong>EN</strong>T<br />

Small bale adapter<br />

For transporting smaller bales: RBG (Ø from 0.9 – 1.4 m) or for<br />

RBG 140 (Ø from 0.7 – 1.1 m)<br />

Pressure relief valve incl. check valve<br />

(Required for wheel loaders and telescopic wheel loaders with an operating pressure<br />

above 200 bar)<br />

Small bale adapter<br />

5 6<br />

POSSIBLE ATTACHM<strong>EN</strong>TS (without installation)<br />

Cat. I and II three-point linkage<br />

Hauer B, Merlo, Merlo ZM3, SMS, MX<br />

Dieci/New Holland, Dieci Dedalus, Amkodor, Manitou, JCB Q-Fit, JCB Compact Tool Carrier,<br />

Weidemann Hydraulik, Kramer, Schäffer up to 3550, Schäffer from 3550T, Atlas,<br />

Claas Scorpion, Zettelmeyer 402, Zettelmeyer 602, Volvo BM, CAT 907H/Liebherr L507,<br />

Liebherr L514, Faresin, Avant, Faucheux, Bobcat, CAT TH 407 C, Giant, Skid Steer, Fendt<br />

Cargo T955/Sennebogen<br />

Cat. II Weiste-Triangle adapter (three-point linkage required)<br />

Other attachments - on request<br />

15

BTGQU<br />

SQUARE BALE GRABBER<br />

1.150<br />

The BTGQU is particularly suited to the transport and stacking of square bales up to 2.1 m. All round bales with a diameter of up to 2 m<br />

can also be transported with ease using the square bale grabber. The special design of the large, rounded gripper arms guarantees gentle<br />

clamping of all bales without any damage.<br />

830<br />

2.150<br />

680<br />

1.250<br />

Dimensions in mm<br />

BASIC MODEL<br />

Base frame with Cat. I and II three-point linkage<br />

Euro-attachment<br />

Large, rounded gripper arms<br />

Hydraulic cylinder for bale securing<br />

Low-maintenance gripper arm guides<br />

Pressure relief valve incl. check valve<br />

TECHNICAL DATA<br />

Weight<br />

L x W x H<br />

<strong>Bale</strong> weight<br />

381 kg<br />

1640 x 2440 x 830 mm<br />

max. 2000 kg<br />

REQUIRED CONNECTIONS<br />

• Double-acting hydraulic connection<br />

16

1 2<br />

IMAGE DESCRIPTION<br />

1) Allows for easy loading and unloading of trailers<br />

2) The BTGQU when feeding a square bale wrapping machine<br />

3) Double bales can also be transported with ease<br />

4) The square bale grabber is also suitable for transporting all round bales<br />

5) The rounded design allows for easy stacking of square bales<br />

FUNCTIONAL DESCRIPTION<br />

3 4<br />

The large opening area means that square bales up to 2.1 m and round bales up to 2 m<br />

can be transported and stacked. The smallest clamping diameter is 680 mm, so smaller<br />

bales can also be transported with ease.<br />

The gripper arms positioned at an angle to one another guarantee a secure grip and<br />

prevent overstretching or damage to the film.<br />

The clamping range can be manually adjusted by 240 mm.<br />

5<br />

Adjustable clamping range<br />

POSSIBLE ATTACHM<strong>EN</strong>TS (without installation)<br />

Merlo, MX<br />

Dieci/New Holland, Manitou, JCB Q-Fit, Weidemann Hydraulik, Kramer, Schäffer from<br />

3550T, Claas Scorpion, Volvo BM, Hydrema, Faucheux, Bobcat, Merlo ZM3<br />

Other attachments - on request<br />

17

GFM<br />

FILM STORAGE<br />

755<br />

The GFM film storage is suitable for transporting 16 rolls of film or 14 rolls of film and two rolls of net or wide film.<br />

1.080<br />

2.340<br />

Dimensions in mm<br />

170<br />

BASIC MODEL<br />

Base frame with Cat. I and II three-point linkage<br />

Hydraulic cylinder for lowering the film storage<br />

TECHNICAL DATA<br />

Weight<br />

L x W x H<br />

250 kg<br />

2340 x 755 x 1080 mm<br />

REQUIRED CONNECTIONS<br />

• Double-acting hydraulic connection<br />

18

1 2<br />

IMAGE DESCRIPTION<br />

1) The film storage in use with the G1015 wrapping machine<br />

2) The GFM is easy to load and unload<br />

3) The film storage can be lowered hydraulically<br />

4) The GFM film storage is especially useful for long periods of field work<br />

5) Up to 16 rolls can be transported on the GFM.<br />

6) There is an optional lighting set with 4 LED work lights and<br />

marker lights<br />

3 4<br />

ADDITIONAL EQUIPM<strong>EN</strong>T<br />

Lighting set<br />

4 LED work lights and 2 marker lights - can be controlled via radio control<br />

Handheld transmitter with radio for lighting set<br />

5 6<br />

POSSIBLE ATTACHM<strong>EN</strong>TS (without installation)<br />

Euro-attachment<br />

Merlo ZM3<br />

Dieci/New Holland, Dieci Dedalus, Kramer, Schäffer up to 3550, Schäffer from 3550T,<br />

Zettelmeyer 602, CAT 907H/Liebherr L507, Bobcat, Faucheux, JCB Q-Fit,<br />

Weidemann Hydraulik, Liebherr L514, Faresin, CAT TH 407 C, Giant, Skid Steer<br />

Cat. II Weiste-Triangle adapter<br />

Other attachments - on request<br />

19

GÖWEIL Maschinenbau GmbH<br />

Davidschlag 11, 4202 Kirchschlag // AUSTRIA<br />

Phone: +43 (0) 7215 2131-0 // Fax.: +43 (0) 7215 2131-9<br />

office@goeweil.com // www.goeweil.com<br />

86,00191C // <strong>EN</strong>