EN | Blade sharpener | MS 100 | Goeweil

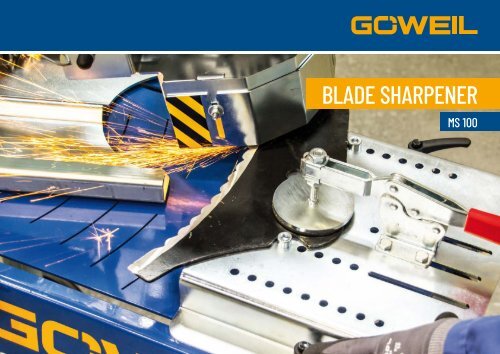

The GÖWEIL blade sharpener MS 100 can be used to sharpen both curved and straight blades with perfect ease. The pitch and length of the sharpener can be adjusted individually and are infinitely variable, making it possible to sharpen blades whose radius is rather tight.

The GÖWEIL blade sharpener MS 100 can be used to sharpen both curved and straight blades with perfect ease. The pitch and length of the sharpener can be adjusted individually and are infinitely variable, making it possible to sharpen blades whose radius is rather tight.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

BLADE SHARP<strong>EN</strong>ER<br />

<strong>MS</strong> <strong>100</strong>

<strong>MS</strong> <strong>100</strong><br />

EQUIPM<strong>EN</strong>T<br />

The GÖWEIL blade <strong>sharpener</strong> can be used to sharpen both curved and straight blades with no effort and in a quick and easy manner. The<br />

pitch and length of the <strong>sharpener</strong> can be adjusted individually and are infinitely variable. This level of flexibility makes it possible to<br />

effortlessly sharpen blades whose radius is rather tight. The lateral rotation limiters prevent sharpening beyond the edge of the blade.<br />

1<br />

BASIC MODEL<br />

Basic model with mobile base frame<br />

1.1 kW (1.5 hp) electric motor<br />

available with 230 V, 400 V (50 Hz) or 120 V (60 Hz)<br />

(delivery excluding plug)<br />

Special cup with coarse grain size<br />

TECHNICAL DATA<br />

L x W x H 930 x 675 x 1,455 mm (36.5” x 26.5” x 57”)<br />

Weight<br />

Rating<br />

69 kg (152 lbs)<br />

1.1 kW (1.5 hp)<br />

Frequency 50 Hz 60 Hz<br />

Speed 2,800 rpm 3,360 rpm<br />

Protection class IP 55<br />

2<br />

Setting for blades with a small radius<br />

Setting for blades with a large radius<br />

3<br />

ADDITIONAL EQUIPM<strong>EN</strong>T<br />

1) Replacement cup wheel<br />

Cup wheel: coarse grain size (included with the scope of delivery)<br />

Cup wheel: fine grain size for increased service life<br />

2) Linear grinding unit<br />

Sharpening straight blades merely requires that you remove the grinding table and<br />

mount it on the angle table. The area you want to sharpen and the cup wheel need<br />

to be aligned horizontally.<br />

3) Cooling unit<br />

Prevents the blade from heating up while being sharpened<br />

2

1 2<br />

HIGHLIGHTS<br />

The <strong>MS</strong> <strong>100</strong> is a compact grinding unit that offers well-conceived solutions and<br />

advantages:<br />

• For all common straight or curved blades on round balers, loading wagons, etc ...<br />

• Grinding angle and radius can be variably adjusted<br />

• Quick and easy blade change without tools<br />

• Lateral rotation limiters<br />

• Short sharpening time<br />

3 4<br />

WORK FLOW<br />

1<br />

2<br />

Positioning of the blade: The stop bolts allow the operator to find the best possible<br />

position on the adjusting plate.<br />

The radii of the most common blades are already preset on the table.<br />

5 6<br />

3<br />

4<br />

5<br />

6<br />

The rotary unit needs to be adjusted. The infinitely variable positioning of the<br />

rotary unit allows for the effortless sharpening of curved blades, sporting both<br />

small and large radii.<br />

The pitch of the grinding unit needs to be adjusted. Since its pitch is infinitely<br />

variable, the grinding unit guarantees the perfect grinding angle every time.<br />

The rotation limiters are set in such a way that the cup wheel remains inside the<br />

cutting surface and does not grind over the edge of the blade while completing<br />

its left-right movement.<br />

You can start sharpening the blade after adjusting all essential settings.<br />

<strong>EN</strong>ERGY SAVINGS<br />

save up to<br />

10% in<br />

fuel<br />

Sharp blades ground to perfect sharpness lower the power requirement of the machine,<br />

allow it to operate with more efficiency and improve the quality of the cut.<br />

A sharp blade is a prerequisite for feed cut to perfection.<br />

3

GÖWEIL Maschinenbau GmbH<br />

Davidschlag 11, 4202 Kirchschlag // AUSTRIA<br />

Tel.: +43 (0) 7215 2131-0 // Fax.: +43 (0) 7215 2131-9<br />

office@goeweil.com // www.goeweil.com<br />

86,00471B // <strong>EN</strong>