istd booklet cover

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

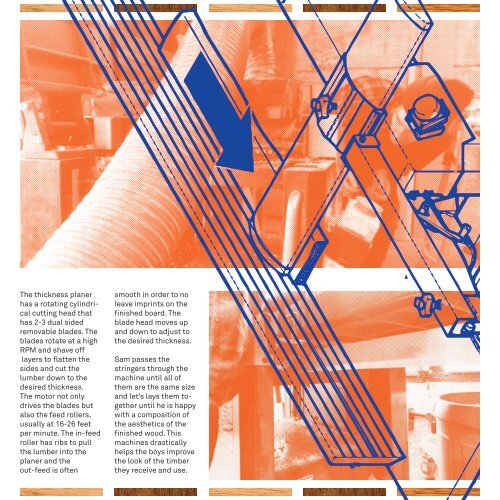

The thickness planer<br />

has a rotating cylindrical<br />

cutting head that<br />

has 2-3 dual sided<br />

removable blades. The<br />

blades rotate at a high<br />

RPM and shave off<br />

layers to flatten the<br />

sides and cut the<br />

lumber down to the<br />

desired thickness.<br />

The motor not only<br />

drives the blades but<br />

also the feed rollers,<br />

usually at 16-26 feet<br />

per minute. The in-feed<br />

roller has ribs to pull<br />

the lumber into the<br />

planer and the<br />

out-feed is often<br />

smooth in order to no<br />

leave imprints on the<br />

finished board. The<br />

blade head moves up<br />

and down to adjust to<br />

the desired thickness.<br />

Sam passes the<br />

stringers through the<br />

machine until all of<br />

them are the same size<br />

and let’s lays them together<br />

until he is happy<br />

with a composition of<br />

the aesthetics of the<br />

finished wood. This<br />

machines drastically<br />

helps the boys improve<br />

the look of the timber<br />

they receive and use.