Maintworld 1/2018

The Use and Misuse of Vibration Analysis // The Industrial Iot Maturity Model // Condition Monitoring in Maritime Applications // Effective Backlog Management

The Use and Misuse of Vibration Analysis // The Industrial Iot Maturity Model // Condition Monitoring in Maritime Applications // Effective Backlog Management

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

INDUSTRIAL INTERNET<br />

The Industrial IoT<br />

Maturity Model<br />

A new model<br />

is helping to<br />

guide decision<br />

makers along a<br />

successful path<br />

in the manufacturing<br />

space.<br />

Text: STEFAN HOPPE,<br />

Global Vice President of OPC Foundation<br />

MANY MANUFACTURING and industrial<br />

companies have realised that digital<br />

transformation will require changes in<br />

the way they do business. Experts will<br />

tell you that digital transformation is not<br />

about making energy discrete, and process<br />

manufacturing more efficient, but is<br />

about establishing new business models<br />

while continuing to make money from<br />

their old business models.<br />

These changes are so substantial that<br />

many talk about a revolution, namely the<br />

4th industrial revolution. The Industrial<br />

Internet of Things – abbreviated to IIoT<br />

and known in Germany as Industrie 4.0<br />

– is a technology trend that is the enabler<br />

of this revolution, and is bringing about<br />

a transformation in the way we do business.<br />

12 maintworld 1/<strong>2018</strong><br />

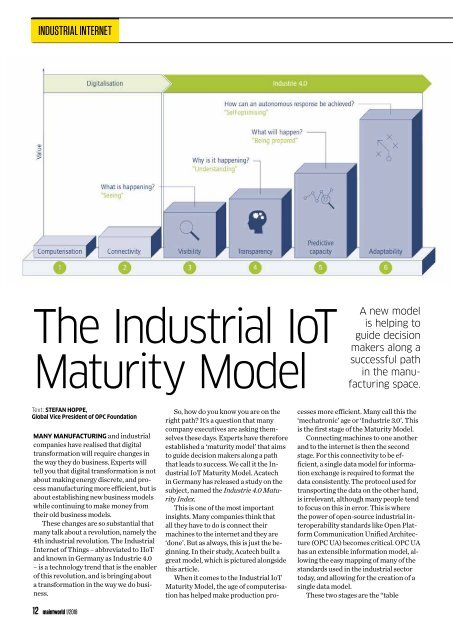

So, how do you know you are on the<br />

right path? It’s a question that many<br />

company executives are asking themselves<br />

these days. Experts have therefore<br />

established a ‘maturity model’ that aims<br />

to guide decision makers along a path<br />

that leads to success. We call it the Industrial<br />

IoT Maturity Model. Acatech<br />

in Germany has released a study on the<br />

subject, named the Industrie 4.0 Maturity<br />

Index.<br />

This is one of the most important<br />

insights. Many companies think that<br />

all they have to do is connect their<br />

machines to the internet and they are<br />

‘done’. But as always, this is just the beginning.<br />

In their study, Acatech built a<br />

great model, which is pictured alongside<br />

this article.<br />

When it comes to the Industrial IoT<br />

Maturity Model, the age of computerisation<br />

has helped make production processes<br />

more efficient. Many call this the<br />

‘mechatronic’ age or ‘Industrie 3.0’. This<br />

is the first stage of the Maturity Model.<br />

Connecting machines to one another<br />

and to the internet is then the second<br />

stage. For this connectivity to be efficient,<br />

a single data model for information<br />

exchange is required to format the<br />

data consistently. The protocol used for<br />

transporting the data on the other hand,<br />

is irrelevant, although many people tend<br />

to focus on this in error. This is where<br />

the power of open-source industrial interoperability<br />

standards like Open Platform<br />

Communication Unified Architecture<br />

(OPC UA) becomes critical. OPC UA<br />

has an extensible information model, allowing<br />

the easy mapping of many of the<br />

standards used in the industrial sector<br />

today, and allowing for the creation of a<br />

single data model.<br />

These two stages are the “table