Maintworld 1/2018

The Use and Misuse of Vibration Analysis // The Industrial Iot Maturity Model // Condition Monitoring in Maritime Applications // Effective Backlog Management

The Use and Misuse of Vibration Analysis // The Industrial Iot Maturity Model // Condition Monitoring in Maritime Applications // Effective Backlog Management

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

TRAINING ADVERTORIAL & PERSONNEL<br />

• Ageing asset base – Companies<br />

increasingly focus on solutions to<br />

cope with problems and challenges<br />

faced by ageing assets. 30 percent<br />

of the asset base is considered either<br />

at end of life or the lifetime of<br />

the assets is already extended. To<br />

deal with this situation companies<br />

could roughly consider two options.<br />

On the one hand, companies<br />

have the option to simply replace<br />

their ageing assets, which has become<br />

easier due to the recent economic<br />

growth. On the other hand,<br />

maintenance organizations could<br />

invest in innovative/technological<br />

solutions to optimize the ageing<br />

asset base. This year, the NVDO<br />

Section Suto have done further research<br />

on this topic in the benchmark<br />

PrestatieManagement with<br />

the Technical University Twente.<br />

• The increasing role of technology<br />

and data within maintenance<br />

– Several of the most<br />

important are linked to technological<br />

developments. In particular,<br />

the combination of the need<br />

for ICT-systems and processing<br />

large amounts of data lead to<br />

higher demand for technological<br />

knowledge. As stated in the Facts<br />

& Figures, companies are looking<br />

for innovative and technological<br />

knowledge<br />

Generally, we see that the maintenance<br />

market is facing some problems<br />

due to the lack of technically-educated<br />

personnel and the ageing asset base.<br />

But, due to the improving economic<br />

climate in combination with technological<br />

innovations, the prospects are<br />

promising. Still, to reach sustainable<br />

growth, maintenance companies<br />

should dare to invest in innovation,<br />

data and technology in order to develop<br />

and attract the right knowledge<br />

and skills.<br />

Shortage of technically-trained personnel<br />

The trend of a shortage of technically-trained personnel is the development with the<br />

most impact for the Dutch maintenance sector in 2017/<strong>2018</strong>. This problem has been<br />

recognised for several years, and has been paid a great deal of attention by the business<br />

community, the government and the media. The current tightness of the labour<br />

market is due to a quantitative and qualitative shortage of personnel.<br />

The quantitative personnel shortage is increasing because of the ageing of the population<br />

on the one hand and the resurgent economy on the other. The qualitative shortage<br />

is caused by an insufficient supply of technical personnel with the necessary competencies.<br />

The qualitative shortage in particular has brought about tight labour market<br />

conditions.<br />

All-rounders needed<br />

Besides problems with the growing demand for technically-trained employees, maintenance<br />

companies have an increasing need for all-rounders, that is to say employees<br />

with an understanding of both technology, ICT and data: we can see a lack of experience<br />

in dealing with data in maintenance organisations. Now and in the future, a maintenance<br />

professional does not only have to be able to carry out maintenance work, but<br />

must also be familiar with the analysis and storage of data so that this can be effectively<br />

converted into useful information.<br />

It is vital that the educational sector and the business community come together<br />

more closely to alleviate the tightness in the labour market. This can be achieved by<br />

closer liaison on the curriculum and the competencies and knowledge that are expected<br />

to be needed in the future, and by partly replacing teaching in the classroom with<br />

learning in practice. After all, the need for technical knowledge is declining. Technicians<br />

want to gain practical knowledge and skills that they can put into immediate use in the<br />

workplace. A number of in-company training centres have already made a start on this.<br />

Governmental responsibility<br />

We can also see that a large number of companies are prepared to enter into partnerships<br />

with each other and with the educational sector to ease the tightness in the<br />

labour market. A key aspect of this is to improve the image of maintenance among<br />

young people. For this to truly succeed, the government also has a role to play. Encouraging<br />

young people to go into technology and innovation, instead of introducing fixed<br />

quotas for these types of courses, would help.<br />

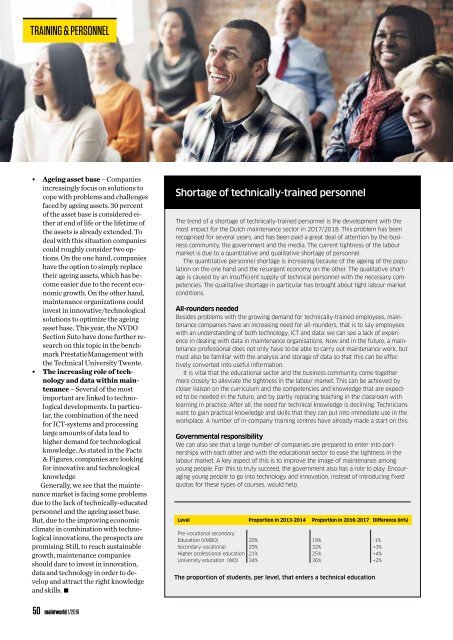

Level Proportion in 2013-2014 Proportion in 2016-2017 Difference (in%)<br />

Pre-vocational secondary<br />

Education (VMBO) 20% 19% -1%<br />

Secondary vocational 29% 32% +3%<br />

Higher professional education 21% 25% +4%<br />

University education (WO) 34% 36% +2%<br />

The proportion of students, per level, that enters a technical education<br />

50 maintworld 1/<strong>2018</strong>