tidu271

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

www.ti.com<br />

5.2 RTD Input Channel<br />

Theory of Operation<br />

5.2.1 Resistance Temperature Detector (RTD) – “Back to Basics"<br />

A Resistance Temperature Detector (RTD) is a sensing element used to measure the temperature as the<br />

element's resistance changes with changes in temperature. RTDs have been constantly in use for many<br />

years to measure the temperature in laboratories and industries. The relationship between an RTD’s<br />

resistance and temperature is highly predictable and allows accurate and repeatable temperature<br />

measurement over wide ranges.<br />

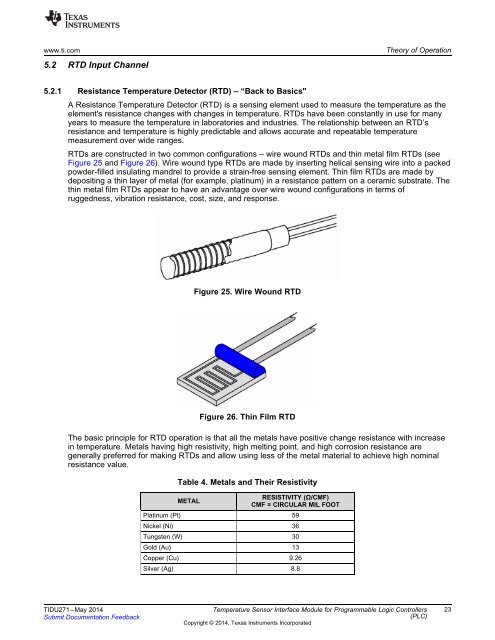

RTDs are constructed in two common configurations – wire wound RTDs and thin metal film RTDs (see<br />

Figure 25 and Figure 26). Wire wound type RTDs are made by inserting helical sensing wire into a packed<br />

powder-filled insulating mandrel to provide a strain-free sensing element. Thin film RTDs are made by<br />

depositing a thin layer of metal (for example, platinum) in a resistance pattern on a ceramic substrate. The<br />

thin metal film RTDs appear to have an advantage over wire wound configurations in terms of<br />

ruggedness, vibration resistance, cost, size, and response.<br />

Figure 25. Wire Wound RTD<br />

Figure 26. Thin Film RTD<br />

The basic principle for RTD operation is that all the metals have positive change resistance with increase<br />

in temperature. Metals having high resistivity, high melting point, and high corrosion resistance are<br />

generally preferred for making RTDs and allow using less of the metal material to achieve high nominal<br />

resistance value.<br />

Table 4. Metals and Their Resistivity<br />

METAL<br />

RESISTIVITY (Ω/CMF)<br />

CMF = CIRCULAR MIL FOOT<br />

Platinum (Pt) 59<br />

Nickel (Ni) 36<br />

Tungsten (W) 30<br />

Gold (Au) 13<br />

Copper (Cu) 9.26<br />

Silver (Ag) 8.8<br />

TIDU271–May 2014<br />

Submit Documentation Feedback<br />

Temperature Sensor Interface Module for Programmable Logic Controllers<br />

(PLC)<br />

Copyright © 2014, Texas Instruments Incorporated<br />

23