Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

when startin{~ the engine. The choke valve is of a =semi=automatic<br />

s type, having a poppet valve incorporated in its design, which<br />

is controlled by a spring. The poppet valve opens automatically<br />

when the engine starts and admits air to avoid over-choking or<br />

flooding of the engine. The mixture required for starting is considerably<br />

richer than that needed to develop power at normal<br />

temperatures. As the engine fires and speed and suction are increased,<br />

the mixture ratio must be rapidly reduced. This change<br />

is accomplished through adjustment of the choke valve and the<br />

automatic opening of the poppet valve to admit more air when the<br />

engine fires.<br />

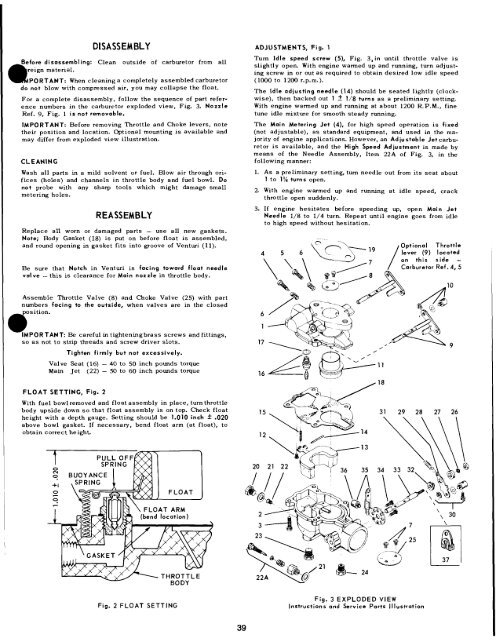

FLOAT SETTING, Fig. 5<br />

If float position is not to the dimension shown, use a long nose<br />

pliers and bend lever close to float body, to obtain correct float<br />

setting.<br />

1-5/32" + 1/32"<br />

L_<br />

~<br />

MOVE GASKET AWAY FROM<br />

CONTACTS HEAD OF PiN<br />

WITHOUT .PRESSURE.<br />

GASKET<br />

FUEL LEVEL<br />

The liquid level in float chamber is 17/32 to 19/32 inch below<br />

top of float bowl. This level was established with a #35 fuel<br />

valve seat at 1½ p.s.i, and a sight tube approximately 1/4 to<br />

9/32 inch i.d.<br />

37