World AirNews June 2018

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

INDUSTRY<br />

NEWS<br />

Since Morf3D was established in late 2015, the company has produced<br />

3D-printed titanium and aluminium components for Boeing<br />

satellites and helicopters. With this investment, Morf3D will collaborate<br />

with Boeing to further develop manufacturing processes and<br />

engineering capabilities.<br />

Morf3D’s metallurgy experts leverage a new set of additive manufacturing<br />

design rules to advance the technology and accelerate<br />

3D-printing capabilities for commercial use.<br />

The company utilizes state-of-the-art software combined with<br />

engineering expertise to significantly reduce mass, and increase<br />

the performance and functionality of manufactured parts.<br />

“We are excited to be a distinguished and trusted partner of<br />

Boeing’s additive manufacturing supplier base, as we continue<br />

to industrialize our processes for the high-rate production of<br />

flight-worthy additively manufactured components,” said Ivan<br />

Madera, CEO of Morf3D.<br />

“This investment will enable us to increase our engineering<br />

staff and expand our technology footprint of EOS M400-4 DMLS<br />

systems to better serve the growing demands of our aerospace<br />

customers.”<br />

Boeing HorizonX Ventures co-led this Series A funding round.<br />

The Boeing HorizonX Ventures investment portfolio is made up of<br />

companies specializing in technologies for aerospace and manufacturing<br />

innovations, including autonomous systems, energy storage,<br />

advanced materials, augmented reality systems and software,<br />

machine learning, hybrid-electric and hypersonic propulsion, and<br />

Internet of Things connectivity.<br />

Boeing’s investment in Morf3D is the latest example of the<br />

company’s achievements with additive manufacturing partners<br />

worldwide.<br />

In March, Boeing and Norsk Titanium received the Aviation<br />

Week Laureate Award for Commercial Supplier Innovation for qualifying<br />

the first additively manufactured structural titanium parts<br />

on a commercial airplane.<br />

In February <strong>2018</strong>, Boeing announced a five-year research<br />

agreement with Swiss-based supplier Oerlikon to develop standard<br />

materials and processes for titanium powder bed additive manufacturing.<br />

Q<br />

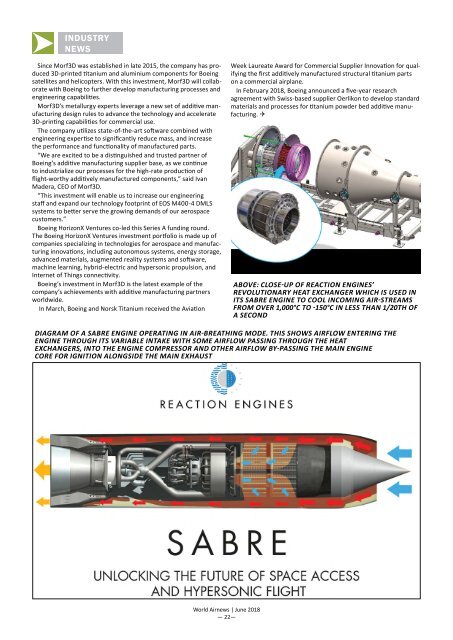

above: Close-up of ReaCtion engines’<br />

RevolutionaRy heat exChangeR whiCh is used in<br />

its sabRe engine to Cool inComing aiR-stReams<br />

fRom oveR 1,000°C to -150°C in less than 1/20th of<br />

a seCond<br />

diagRam of a sabRe engine opeRating in aiR-bReathing mode. this shows aiRflow enteRing the<br />

engine thRough its vaRiable intake with some aiRflow passing thRough the heat<br />

exChangeRs, into the engine CompRessoR and otheR aiRflow by-passing the main engine<br />

CoRe foR ignition alongside the main exhaust<br />

PHENOM 300: PRESENCE AND POWER<br />

UNLIKE ANY OTHER JET<br />

“I was wowed by the difference between Phenom 300 and any other jet you could fly single pilot. It’s just an<br />

awesome aircraft. It’s a magic carpet. You pull up on the ramp, and you’re looking down on other jets, literally.<br />

The door, the stairs, the entrance to the aircraft − it’s the ultimate ramp presence. And then the raw power of<br />

the aircraft is phenomenal. Especially when flying in mountainous areas, which we do a lot, it’s great to have<br />

that confidence of power.<br />

So there was no question when we started looking for our next jet: the Phenom 300. It’s elegant. It’s a sexy<br />

plane. It can hold a lot of people, but the sheer, unadulterated power that it has to climb, and the power it has<br />

to fly fast, is unlike any other jet we’ve flown. It is the best jet you can fly single pilot.”<br />

- Mary Compton, Owner, Vivo Volare LLC<br />

Watch Mary’s story and request more information at<br />

EmbraerExecutiveJets.com/Mary<br />

The best-selling light jet in the world for six years running, Embraer’s Phenom 300 platform has achieved breakthrough status and dominates as the<br />

fastest, longest range single-pilot aircraft on the market. And now, with the introduction of the brand-new Phenom 300E, a whole new standard in value<br />

and customer experience has been set. Designated “E” for “enhanced,” this modern, clean-sheet light jet delivers top-tier performance and next-generation<br />

avionics, along with a revolutionary new interior design for improved ergonomics, ease of maintainability, advanced connectivity and unmatched comfort and<br />

space. Add to that the industry-exclusive upper technology panel, plus a generous baggage compartment and low operating costs, and it’s easy to see why<br />

the Phenom 300E is truly in a class by itself.<br />

<strong>World</strong> Airnews | <strong>June</strong> <strong>2018</strong><br />

— 22—<br />

<strong>World</strong> Airnews | May <strong>2018</strong><br />

— 75 —