Manufacturing Machinery World July 2018

Machinery World was launched in 1982 to serve the machinery & production engineering market.

Machinery World was launched in 1982 to serve the machinery & production engineering market.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

JULY <strong>2018</strong><br />

www.<strong>Machinery</strong>.world<br />

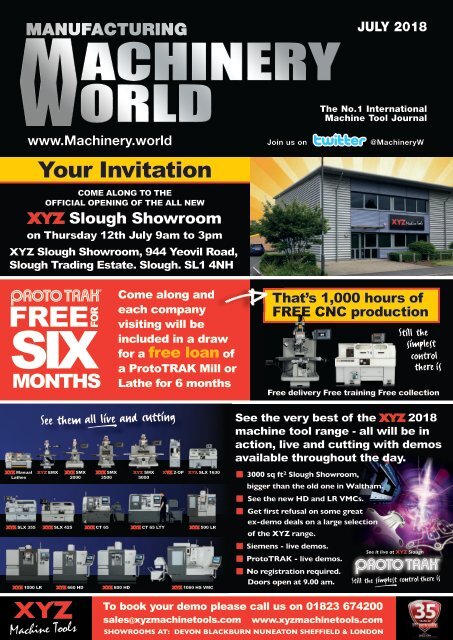

Your Invitation<br />

COME ALONG TO THE<br />

OFFICIAL OPENING OF THE ALL NEW<br />

XYZ Slough Showroom<br />

on Thursday 12th <strong>July</strong> 9am to 3pm<br />

XYZ Slough Showroom, 944 Yeovil Road,<br />

Slough Trading Estate. Slough. SL1 4NH<br />

Join us on<br />

The No.1 International<br />

Machine Tool Journal<br />

@<strong>Machinery</strong>W<br />

FREE FOR<br />

SIX<br />

MONTHS<br />

XYZ Manual<br />

Lathes<br />

XYZ SLX 355<br />

XYZ<br />

EMX<br />

XYZ SMX<br />

2000<br />

XYZ SMX<br />

3500<br />

Come along and<br />

<br />

XYZ SLX 425<br />

XYZ CT 65<br />

each company<br />

visiting will be<br />

included in a draw<br />

for a free loan of<br />

a ProtoTRAK Mill or<br />

Lathe for 6 months<br />

XYZ SMX<br />

5000<br />

XYZ CT 65 LTY<br />

XYZ 2-OP<br />

XYZ SLX 1630<br />

XYZ 500 LR<br />

XYZ 1000 LR XYZ 660 HD XYZ 800 HD XYZ 1060 HS VMC<br />

That’s 1,000 hours of<br />

FREE CNC production<br />

To book your demo please call us on 01823 674200<br />

sales@xyzmachinetools.com www.xyzmachinetools.com<br />

<br />

<br />

<br />

<br />

Free delivery Free training Free collection<br />

See the very best of the XYZ <strong>2018</strong><br />

machine tool range - all will be in<br />

action, live and cutting with demos<br />

available throughout the day.<br />

n 3000 sq ft 2 Slough Showroom,<br />

bigger than the old one in Waltham.<br />

n See the new HD and LR VMCs.<br />

n Get rst refusal on some great<br />

ex-demo deals on a large selection<br />

of the XYZ range.<br />

n Siemens - live demos.<br />

n ProtoTRAK - live demos.<br />

n No registration required.<br />

Doors open at 9.00 am.<br />

See it live at XYZ Slough<br />

<br />

SHOWROOMS AT: DEVON BLACKBURN NUNEATON SHEFFIELD & LONDON<br />

SINCE 1984

0121 54 11 444<br />

Mantechmachinery.com<br />

mantechmachinery@gmail.com<br />

sales@mantechmachinery.com<br />

Mantech has introduced affordable Laser and Plasma Cung to the UK market. We offer a wide<br />

range of machines to suit your company’s needs. The Fibre Laser is capable of cung at high<br />

speeds and can cut a wide range of material types, including round and square tubes.<br />

Fibre Laser T<br />

achine<br />

Available in lengths up to 6 Metres, Diameters up<br />

to 215mm for round or square tube<br />

We have just installed a<br />

6 meter tube laser<br />

here in Birmingham<br />

Tables<br />

Offering bespoke tables to meet your<br />

Our Plasma tables comes with a wide range of power sources from<br />

Min 40A to maximum 200A<br />

vailable) our<br />

standard table includes: stainless steel water bed,<br />

sensors, Plasma cut so e, Digital torch height control,<br />

Also delivery & training are included.<br />

Prices from £9,435 + VAT<br />

Models Available:<br />

Model P14 (1400 x 1400mm) Model P26 (2600 x 1400mm)<br />

Model P31 (3100 x 1600mm) Model JD45 (4500 x 2200mm)<br />

M<br />

We Stock a large range of<br />

sheet metal machinery including:<br />

Press Brakes . Hydraulic Folders .<br />

ydr<br />

Corner Notchers.<br />

Please do not hesitate to contact us for a quote. We can give immediate quotes for any machine.<br />

Our product range offers great value for money and prices are inclusive of<br />

All of our machines are fully w<br />

years.

CONTENTS JULY <strong>2018</strong><br />

Front Cover:<br />

XYZ Machine Tools<br />

MANAGING DIRECTOR:<br />

Carole Titmuss<br />

NEWS EDITOR:<br />

Pat Fairfax<br />

FEATURES EDITOR:<br />

Danielle Titmuss MSc<br />

SALES:<br />

Lorraine Compton<br />

PRODUCTION:<br />

Ian Purves,<br />

James Kennett,<br />

Jonathan Milburn<br />

SUBSCRIPTIONS:<br />

Kay Knight<br />

PUBLISHER<br />

Carole Titmuss<br />

This journal includes editorial<br />

photographs provided and paid for<br />

by suppliers.<br />

<strong>Manufacturing</strong> <strong>Machinery</strong> <strong>World</strong> is<br />

available on subscription annual rate<br />

UK £44, Europe £66, Overseas £90<br />

Single Copies £4 UK, £8 Overseas.<br />

AUCTIONS 40-42<br />

FEATURES:<br />

Finishing, Cleaning & Degreasing 29-33<br />

SERVICES DIRECTORY 36-39<br />

Our comprehensive guide to Product & Service Providers to the<br />

manufacturing industry.<br />

NEXT MONTHS FEATURES<br />

Sawing Machines & Cutting Tools.<br />

Lubricants & Coolants.<br />

Published by:-<br />

SHEEN PUBLISHING LTD<br />

50 QUEENS ROAD<br />

BUCKHURST HILL, ESSEX IG9 5DD<br />

TELEPHONE: 020 8504 5912<br />

020 8504 1661<br />

International: +44 20 8504 1661<br />

FACSIMILE: 020 8505<br />

4336<br />

International: +44 20 8505 4336<br />

www.machinery.world<br />

Email: info@machinery.world<br />

Twitter: @<strong>Machinery</strong>W<br />

MANUFACTURING MACHINERY<br />

WORLD is published monthly and is<br />

circulated to senior personnel who<br />

influence the buying and selling of<br />

new and used metal working<br />

machinery worldwide.<br />

©Sheen Publishing Ltd. All rights<br />

reserved. No part of this publication<br />

june be reproduced or transmitted in<br />

any form or by any means, including<br />

photocopying and recording, without<br />

the written permission of the<br />

publishers. Such written permission<br />

must also be obtained before any<br />

part of this publication is stored in a<br />

retrieval system of any nature.<br />

Customer service has always been a priority<br />

at XYZ Machine Tools from initial sale<br />

through to ongoing support for machine<br />

installations.<br />

Page 12.<br />

As one of the UK’s leading providers of<br />

deburring and surface finishing equipment<br />

and systems, Ellesco has developed a<br />

reputation for high levels of customer<br />

support and service.<br />

Page 35.<br />

w w w . m a c h i n e r y . w o r l d<br />

<strong>Machinery</strong> <strong>World</strong>, <strong>July</strong> <strong>2018</strong> 3

NEWS NEWS NEWS<br />

MEDICAL IMPLANT COMPANY INSTALLS<br />

TWO NEW TORNOS MACHINES<br />

For more than 20 years, Königsee Implantate<br />

based in Königsee, deep in the Thuringian<br />

Forest in Germany, has been developing and<br />

producing implants and instruments for<br />

traumatology, orthopedics and spinal<br />

surgery with enormous success. In the course<br />

of continuous process improvements, two<br />

new Tornos EVODeco 16 machines have<br />

been purchased.<br />

In the medical industry, Königsee is a<br />

significant manufacturer with a history that<br />

dates back to the end of <strong>World</strong> War I. In 1919,<br />

orthopedic technician Otto Bock founded the<br />

company in Berlin to provide disabled war<br />

veterans with prostheses and other<br />

orthopedic products. Shortly afterwards, the<br />

company moved to Königsee, in Thuringia.<br />

This was the origin for Königsee Implantate<br />

GmbH, which was founded by Erich<br />

Orschler in 1993.<br />

The success story started with a small<br />

machine inventory and the strong<br />

determination of its employees. Initially, the<br />

company focused exclusively on the<br />

development and manufacturing of osteosynthesis<br />

systems for traumatology and<br />

orthopedics. For more than 10 years now, it<br />

OELHELD EXPANDS UK<br />

PRESENCE<br />

Renowned as an industry leading manufacturer and supplier of<br />

metalworking fluids, water-soluble lubricants and filtration and<br />

extraction systems, Oelheld UK has now expanded its UK operation.<br />

The Denbigh headquarters in North Wales has now doubled in size<br />

with the acquisition of a new warehousing unit.<br />

Purchasing the adjacent unit, the additional warehouse unit has<br />

doubled the company’s storage space from 6000sq/ft to 12,000sq/ft.<br />

This acquisition has been driven by years of continual growth with<br />

sales of metalworking fluids, filtration systems and EDM<br />

consumables all rising consistently for a number of years.<br />

Discussing the new acquisition, Oelheld UK Managing Director,<br />

Mr Peter Mangan says: “This move is essential for our business to<br />

continue on its trajectory of continued growth. For Oelheld to meet<br />

the demands of our customers with next day availability of our<br />

products, the additional storage facility is a must. The new area will<br />

also provide space for the manufacture of bespoke filtration systems<br />

for all types of metal working applications. Our goal has always been<br />

to deliver first class solutions and service to our customer base, this<br />

expansion is the next step in supporting our growth journey whilst<br />

ensuring we maintain our customer service and support levels.”<br />

Tel.: 01745 814777<br />

sales@oelheld.co.uk<br />

www.oelheld.co.uk<br />

has also been offering solutions for spinal<br />

surgery.<br />

The products for almost all bone sections,<br />

from the collarbone to the toes, drastically<br />

speed up the healing process of fractures<br />

compared to conventional methods of<br />

treatment. New solutions constantly arise<br />

from the close collaboration with physicians<br />

and surgical teams. The development<br />

projects comprise the complete path of the<br />

value chain, from the idea and development<br />

of a prototype to the manufacture of the<br />

product. During this process, painstaking<br />

attention is paid to quality, since it is the<br />

basic requirement for the long service life<br />

and safe use of implants. This is why they<br />

purchased two new EVODeco 16 machines<br />

from Tornos.<br />

In layman's terms, an osteo-synthesis<br />

system consists of a plate that is matched<br />

with the anatomy and screwed onto the<br />

bones with a variable number of screws of<br />

different lengths and diameters. Königsee<br />

comprises the entire manufacturing process<br />

from purchase and planning to the milling,<br />

turning, grinding and galvanizing to the final<br />

inspection and warehousing. Design<br />

concepts are translated into series<br />

production. The pricing pressure has<br />

reached the medical industry and this means<br />

that top quality produce from Germany can<br />

only be competitive by applying a<br />

sophisticated manufacturing strategy. For<br />

this reason, Königsee has invested in Tornos.<br />

Tel: 01530 513100<br />

sales@tornos.co.uk<br />

www.tornos.com<br />

ELESA CHROME RIVALS<br />

STAINLESS STEEL<br />

Elesa’s chrome on plastic technology is particularly suitable for<br />

applications on machines and equipment whose parts, for hygienic<br />

reasons, must be frequently cleaned by using water jets or steam. It is<br />

therefore often a suitable replacement for stainless steel in many<br />

arduous or specialist situations at a very considerable cost saving.<br />

Example items are the VC.692-CR lobe knob series for machine<br />

control, coupled with ERX-CR adjustable clamping handles and the<br />

CQT.FM-CR quarter turn lever latches for enclosure locking to IP65.<br />

This chrome finished polyamide technopolymer range is an<br />

expanding feature within the extensive Elesa portfolio of standard<br />

industrial components as the chrome-plating finish makes the<br />

surface finish semi-glossy and homogeneous to facilitate cleaning<br />

operations and is tested at -30°C up to +80°C.<br />

The chrome-plated surface is resistant to wear, scrapes and<br />

shocks. In laboratory tests carried out at ambient temperature (23°C),<br />

the chrome-plated surface proved to be resistant to: sea water,<br />

detergents, acetone, ethyl alcohol, formic acid and chlorine solutions.<br />

www.elesa.com www.twitter.com/ElesaUK<br />

4 <strong>Machinery</strong> <strong>World</strong>, <strong>July</strong> <strong>2018</strong>

<strong>Machinery</strong> <strong>World</strong>, <strong>July</strong> <strong>2018</strong> 5

NEWS NEWS NEWS<br />

GERMAN CHANCELLOR MERKEL, HAND IN HAND<br />

WITH THE ROBOTS OF TOMORROW<br />

Collaborating with robots and controlling them with gestures? German<br />

chancellor Angela Merkel experienced first-hand how this can be<br />

achieved in her opening day tour at the Hannover Messe <strong>2018</strong> during an<br />

impressive live demonstration.<br />

At the IBG Automation booth, Angela Merkel and the Mexican<br />

President Enrique Peña Nieto and his wife Angélica Rivera, got up close<br />

and in person with the robotic hands from SCHUNK. Both 5-finger hands<br />

of the competence leader for gripping systems and clamping technology<br />

are the world's first robotic grippers that have been certified and<br />

approved for collaborative use by the German Social Accident Insurance<br />

(DGUV).<br />

Behind the playful exterior lies real technology: In industrial and<br />

service robotics applications of the future, it will be possible to control,<br />

configure and interact with robots only by using gestures, and without any<br />

knowledge of programming. The automation specialist IBG Automation<br />

has developed an application that does just that. The robot is controlled by<br />

gestures or speech and calculates its movement in real time. Using a 3D<br />

camera, the system is able to follow the hand and<br />

arm movements of the user and imitate them 1:1.<br />

The movements of the robot are mainly<br />

dictated by the hands of the user. This<br />

technology will make working next to robots<br />

possible, hand in hand in the future. For<br />

assembly tasks, for example, parts will be able<br />

to be directly transferred into or out of the<br />

robot's hands. "NXT LEVEL human/robot<br />

collaboration" can be used anywhere that there<br />

is a great deal of manual work necessary and<br />

where there are high requirements on quality.<br />

For the first time ever, it is making complete<br />

cooperation between humans and robots<br />

possible without any separation in time or<br />

space. The user is not bound to a terminal, but<br />

can move around freely and control the robot,<br />

The installation of a new Hartford Infinity twincolumn<br />

vertical machining centre has not only<br />

provided Steel Dynamics UK with the enlarged<br />

capability and capacity that it needed, but the<br />

machine is also producing cycle time reductions<br />

of at least 30 per cent compared with previous<br />

routines.<br />

“And with improved fixturing methods plus<br />

enhancements to the tooling being used, we<br />

fully expect to further improve on those<br />

machining time savings in the near future,”<br />

according to the Blackburn-based company’s<br />

the entire automated system or individual<br />

functions via a smartphone or smartwatch,<br />

adjusting parameters and retrieving<br />

information during maintenance or conversion<br />

processes. The system integrates the human<br />

workplace and innovative robot technology<br />

into a shared and future-oriented collaborative<br />

environment.<br />

The mechatronic SCHUNK SVH gripping<br />

hand designed for applications in assistance<br />

and service robotics is staggeringly similar to its<br />

human counterpart in terms of size, shape and<br />

mobility. Its five fingers can carry out all kinds<br />

of gripping operations with the help of a total of<br />

nine drives. Elastic surfaces on the front<br />

phalanxes ensure a reliable hold on the objects<br />

NEW HARTFORD DOUBLE-COLUMN VMC MAKES A<br />

DYNAMIC IMPRESSION IN BLACKBURN<br />

operations director Andy Berry.<br />

Supplied by T W Ward CNC <strong>Machinery</strong><br />

(Ward CNC), Hartford’s exclusive agent in the<br />

UK and Ireland, the Infinity HSA420 has X, Y<br />

and Z axes travels of 4,000 mm by 2,000 mm by<br />

1,000 mm and, capable of accommodating<br />

workpieces weighing 12, 000 kgs, the machine is<br />

out-performing Steel Dynamic UK’s two<br />

existing, older vertical machining centres for<br />

both speed and capability, says Mr Berry.<br />

“It’s the largest machine we’ve ever<br />

installed,” he continues, “and while so far it has<br />

largely been used on a relatively<br />

new nuclear-based contract –<br />

involving predominantly milling<br />

operations on prismatic stainless<br />

steel workpieces – it has perfectly<br />

complemented our existing<br />

manufacturing capabilities based<br />

around ISO 9001: 2008<br />

accreditation. These include water<br />

jet, plasma and laser cutting, as<br />

well as radial arm drilling and<br />

vertical boring to 1,350 mm<br />

diameter.”<br />

Steel Dynamics UK is an<br />

established supplier of a wide<br />

range of components to customers<br />

being gripped. Because the hand can perform<br />

and imitate numerous gestures, the visual<br />

communication between humans and the<br />

service robot has become significantly easier.<br />

This simplifies programming and promotes a<br />

sense of acceptance for robots in the human<br />

environment. The hand is designed in such a<br />

way that a person is not injured during their<br />

daily interactions. The open and closed-loop<br />

control electronics as well as the power<br />

electronics are fully integrated in the wrist,<br />

meaning that particularly compact solutions<br />

can be achieved.<br />

Tel: (+44) 01908 611127<br />

info@gb.SCHUNK.com<br />

www.gb.SCHUNK.com<br />

in varied industry sectors ranging from<br />

architectural, oil and gas, through to food and<br />

beverage processing as well as petrochemical,<br />

and in materials that also include duplex, nickel<br />

and carbon alloys, aluminium, copper and<br />

brass.<br />

Its new Hartford machining centre is ideally<br />

suited to handling all these materials, with a<br />

solid construction based on a one-piece heavy<br />

duty cast iron bed that provides high accuracy<br />

and stability.<br />

Linear guideways permit impressive feed<br />

and traverse rates – up to 12,000 mm/min and<br />

20 m/min in X (18 m/min in Y and 16m/min in<br />

Z), respectively – while, as standard, the 22 kW<br />

spindle motor is complemented by a 20-station<br />

automatic toolchanger.<br />

For Steel Dynamics, however, Ward CNC<br />

was able to not only provide the machine on a<br />

very short delivery – to satisfy the customer’s<br />

urgent need to update its capability – but it also<br />

provided a machine with a higher specification<br />

main motor (26 kW) and larger capacity<br />

toolchanger (40 tools) again to meet Steel<br />

Dynamics’ specific demands.<br />

Tel: 0114 276 5411<br />

lwilson@wardcnc.com<br />

www.wardcnc.com<br />

6 <strong>Machinery</strong> <strong>World</strong>, <strong>July</strong> <strong>2018</strong>

PRECISION<br />

GRINDING<br />

MACHINES<br />

‘Always Excel’<br />

Colliery Lane, Exhall, Coventry, United Kingdom . CV7 9NW<br />

www.excelmachinetools.co.uk<br />

sales@excelmachinetools.co.uk<br />

GRB GRINDERS<br />

‘First Class Service’.<br />

W B Alloys<br />

Tel: +44 (0)24 7636 5255<br />

/excelmachinetools<br />

/AlwaysExcel<br />

UK PARTNERS FOR GERMAN STURMER GROUP

NEWS NEWS NEWS<br />

GETTING A<br />

KNIGHT OF THE<br />

RAILS BACK UP<br />

TO STEAM<br />

The workshops of the Llangollen Railway<br />

provide maintenance for its own rolling stock as<br />

well as supporting other heritage railways<br />

around the UK and building brand new steam<br />

locomotives to order. Like many such<br />

organisations it relies on donations, not only of<br />

cash and time, but also machine tools. However,<br />

when one particular project came up the<br />

decision was taken to invest in new machinery<br />

in the form of an XYZ SLX 425 ProTURN lathe.<br />

The project in question was the restoration<br />

of the iconic streamlined A4 Class locomotive<br />

Sir Nigel Gresley. Built in 1937, the Sir Nigel<br />

Gresley holds the post-war steam speed record<br />

of 112 mph (180 km/h) which it achieved on 23<br />

May 1959 while hauling a full train of<br />

passengers. In its life it has had many<br />

overhauls, and the latest is taking place in full<br />

public view at the National Railway Museum in<br />

York by the Sir Nigel Gresley Locomotive<br />

Company Volunteers, except for its boiler,<br />

which has been stripped of its streamlining and<br />

transferred to Llangollen for refurbishment and<br />

re-certification. As part of this boiler restoration<br />

the boiler stays must be replaced, these<br />

threaded shafts support and brace the metal<br />

walls of the firebox against the pressure (up to<br />

250 psi) and are an important safety feature. As<br />

the boiler on the Sir Nigel Gresley requires 296<br />

of these stays of various lengths with<br />

Whitworth threads on either end an upgrade<br />

In an effort to help members of the welding<br />

community master their craft, ESAB Welding &<br />

Cutting Products has created the ESAB Elite, a<br />

team of respected welders from across the<br />

globe, to share wisdom and provide practical<br />

welding advice through social media. To kick<br />

off the program, each partner has created<br />

welding tips videos for esab.com/elite and the<br />

playlist on ESAB’s YouTube channel.<br />

“The welding industry has embraced<br />

Instagram and YouTube as ways to share work,<br />

solve problems and challenge each other to see<br />

who can lay the best beads. The ESAB Elite<br />

program adds fuel to their fire and channels the<br />

energy of these social media leaders so that the<br />

industry collectively benefits,” says Steven<br />

from manual turning was deemed wise.<br />

Llangollen Railway therefore took the<br />

decision to invest in an XYZ SLX 425 Proturn<br />

lathe with a 1.25 m between centre distanced<br />

length. A decision that is paying dividends as<br />

each boiler stay can now be machined complete<br />

in half the time that they previously took on a<br />

manual lathe. “The ProtoTRAK control makes<br />

life very easy as it guides you through<br />

everything, the TRAKing feature is very handy<br />

and the Do-One canned cycle feature in the<br />

control is extremely useful for machining<br />

features such as radii and chamfers. In addition<br />

to the easy conversational programming, we<br />

always use the Verify graphical system for<br />

Molenda, Director of Global MarCom and<br />

Marketing Strategies, ESAB.<br />

The inaugural Elite class represents a global<br />

team of fabricators from diverse backgrounds<br />

and skill sets. From creating custom metal roses<br />

to designing the craziest food trucks in Texas,<br />

each partner has undeniable talent and a desire<br />

to see the industry grow. They weld for a living,<br />

but many also have side gigs that allow them to<br />

show off their creativity in metalworking to<br />

thousands of followers through social media.<br />

To stay up-to-date with this Elite team of<br />

talented welders, sign up to receive updates at ,<br />

check out the Hot Welding Tips playlist and<br />

follow the team directly on their Instagram<br />

accounts.<br />

Meet the Elite<br />

The ESAB Elite team members represent a<br />

highly diverse group of backgrounds and skill<br />

sets. Here are the ESAB Elite team members:<br />

• James Flatman (@narcissisticwrench) – A<br />

former bike mechanic from Australia, this TIG<br />

welder now uses his skills to construct the<br />

craziest food trucks in Texas with Cruising<br />

Kitchens.<br />

• Charis Williams (@chariswilliams) – A<br />

professional designer from the UK, this TIG<br />

added reassurance,” says machinist Michael<br />

O’Toole.<br />

The ‘Do-One feature in the ProtoTRAK SLX<br />

control used on ProTURN lathes allows the<br />

operator to combine manual and CNC<br />

operation to create radii, tapers, fillets and<br />

repair threads. The operator simply inputs the<br />

angle or radii into the control and then by using<br />

the electronic handwheels can manually create<br />

the shape or form required. For one-off and<br />

low-volume batches this can generate<br />

significant time savings.<br />

Tel: 01823 674200<br />

nigel.atherton@xyzmachinetools.com<br />

www.xyzmachinetools.com<br />

ESAB GATHERS ELITE TEAM OF WELDERS TO<br />

SHARE WELDING HOW-TO ADVICE AND INSIDER TIPS<br />

welder specialises in creating upcycled and<br />

reinvented furniture for homes and businesses.<br />

• Joe Giamanco (@joe_welderup) – This<br />

fabricator specializes in TIG welding and works<br />

on custom car and truck builds at Welderup.<br />

• Matti Christensen (@mattichristensen) –<br />

This new production fabricator from West<br />

Coast Sweden uses his MIG skill for many<br />

different jobs for work and play.<br />

• Andrea Havlin (@hotwork247) – With more<br />

than a decade in the industry, this skilled stick<br />

welder and veteran steelworker shows off her<br />

projects to more than 12,000 followers on<br />

Instagram.<br />

• Scott Raabe (@scott_raabe) – A pipe welder<br />

by trade who uses his spare time to create<br />

custom metal designs and art for his business,<br />

CleanCutMetalWorks.<br />

• Sanna Camilla (@saannacamilla) – This<br />

certified TIG welder shows off her technical<br />

welding skills for more than 33,000 Instagram<br />

followers.<br />

• Brian Lambert (@rollingbombfab) – From<br />

day-to-day work on propane delivery trucks to<br />

creating art from his welds, this TIG welder<br />

shows off his skills to nearly 40,000 followers on<br />

Instagram.<br />

www.esab.com/elite<br />

8 <strong>Machinery</strong> <strong>World</strong>, <strong>July</strong> <strong>2018</strong>

GAUGES LTD<br />

PENICO ROTARY<br />

GRINDING TABLE<br />

• Converts surface grinders<br />

to rotary work<br />

• Robust construction<br />

For further details contact<br />

Penico Gauges Ltd<br />

Tel: 01274 511044<br />

Fax: 01274 510770<br />

Email:<br />

penicogauges@yahoo.co.uk<br />

Web: www.penico.com<br />

<strong>Machinery</strong> <strong>World</strong>, <strong>July</strong> <strong>2018</strong> 9

NEWS NEWS NEWS<br />

ESAB PARTNERS WITH PROACTIVE GAS SAFETY FOR CP7<br />

GAS EQUIPMENT INSPECTOR TRAINING COURSES<br />

ESAB, one of the world leader in welding<br />

and cutting technologies, is excited to be<br />

entering into a partnering with Proactive Gas<br />

Safety Ltd (PGS) for the provision of Oxy-<br />

Fuel CP7 Inspector courses, with successful<br />

candidates being awarded a nationally<br />

accredited EAL (Excellence in Achievement<br />

LTD) Level 3 QCF Qualification<br />

(Qualifications and Credit Framework) This<br />

is the highest level of achievement available<br />

for compressed gas safety training in the UK<br />

and qualifies individuals to undertake<br />

annual inspections of oxyacetylene/propane<br />

equipment as required by<br />

BCGA CP7 (British Compressed Gases<br />

Association Code of Practice 7).<br />

Under this scheme, successful completion<br />

of the two-day course and QCF Qualification<br />

provides a three-year Gas Safety Passport for<br />

inspecting gas equipment. The credit cardsized<br />

Gas Safety Passport shows the<br />

Accredited Inspector’s photograph, the date<br />

on which the course was taken and the date<br />

on which re-certification is required. This is<br />

particularly useful when registered<br />

inspectors are working on customers’ sites<br />

and need to present evidence of their<br />

qualification.<br />

The two-day Inspector course includes<br />

classroom training, practical demonstrations<br />

and hands-on sessions. Multiple-choice tests<br />

are conducted throughout the course and<br />

there is a formal exam at the end that<br />

candidates must pass to be awarded their<br />

certificate.<br />

There will no longer be a requirement for<br />

annual refresher training as re-certification<br />

will take place on 3-yearly cycle. e.g. <strong>2018</strong> 2<br />

day training; 2021 -1 day refresher; 2024 -2<br />

day refresher; 2027 - 1 day refresher.<br />

PGS Gas Safety Passport holders are<br />

given comprehensive technical support and<br />

unlimited access to downloadable<br />

documentation from PGS website.<br />

Helen Brewin, Commercial Director of<br />

Proactive Gas Safety Ltd, comments: “PGS<br />

are delighted to be in a position to help<br />

ESAB’s customers with Gas Equipment<br />

Inspector Qualification; we view this as a<br />

long-term partnership through which we<br />

will support ESAB and its customers.”<br />

The two-day inspector course costs £472.50 +<br />

VAT<br />

Dates currently booked at PGS in<br />

Cheshire are: 18-19 <strong>July</strong>, 17-18 October.<br />

Further venues and dates will be released<br />

shortly.<br />

ESAB is a recognised leader in the<br />

welding and cutting industry. From timehonoured<br />

processes in welding and cutting<br />

to revolutionary technologies in mechanised<br />

cutting and automation, ESAB’s filler metals,<br />

equipment, and accessories bring solutions to<br />

customers around the globe.<br />

Tel: 0800 389 3152<br />

www.esab.com<br />

ORGANISATION, EFFICIENCY AND CONFORMITY AT JOTA<br />

ADVANCED ENGINEERING<br />

Built around its successful motorsport team<br />

the Jota Group has used the skills and<br />

experience that winning at Le Mans brings to<br />

develop a business that spans Jota Sport<br />

which designs, builds and supports racewinning<br />

GT, LMP2 and LMP1 class cars; Jota<br />

Aviation, a successful aviation charter<br />

business, and Jota Advanced Engineering, a<br />

relatively new, but dynamic sub-contract<br />

machining facility. The driving force behind<br />

the Group’s success is its passion for<br />

everything it does, whether preparing a racewinning<br />

Le Mans car, flying people and<br />

cargo around the globe or precision<br />

machining exotic materials. The group’s aim<br />

is simply to be the best, by focusing on<br />

attention to detail and delivering on its<br />

promises.<br />

While Jota Advanced Engineering is the<br />

latest name to join the Group, machining has<br />

been a part of the business for many years.<br />

Initially the race team technicians used<br />

manual machines to create one-off bespoke<br />

parts on, this developed into a small machine<br />

shop contained in the race teams workshop.<br />

The growth in demand for more complex<br />

parts for its own cars, along with<br />

opportunities in the sub-contract machining<br />

sector, saw a need for expansion and Jota<br />

Advanced Engineering was created. Already<br />

accredited with ISO9001 Jota Advanced<br />

Engineering is working towards further<br />

accreditations in the automotive sector that<br />

will assist it to further expand its already<br />

nationwide customer base from the<br />

Automotive, motorsport aerospace and<br />

power generation sectors.<br />

“We have built the business around the<br />

Group’s common goal of delivering results,<br />

in our case drawing on our precision<br />

engineering skills to create tight tolerance<br />

work, often in difficult to machine materials,<br />

and in many cases taking on work that others<br />

didn’t want to do,” says Ryan Goodger,<br />

Director, Jota Advanced Engineering. In<br />

order to achieve this the company has<br />

invested in a range of high-tech machine<br />

tools, including multi-axis turning centres<br />

with live tooling and a five-axis machining<br />

centre. These are supported by the latest in<br />

CADCAM and production control software,<br />

along with a team of highly skilled engineers.<br />

With the growth in the machining business<br />

and number of machines, came a<br />

requirement for more tools and<br />

workholding, which in turn needed to be<br />

stored in a planned and efficient manner.<br />

With the race team, Jota Sport, already<br />

using Fami storage in its race bays it was a<br />

logical step to call System Store Solutions<br />

back in to design the workshop storage<br />

layout for Jota Advanced Engineering.<br />

“Organisation and image is key in the sectors<br />

that we operate in so to have a consistent<br />

look running through the race team and<br />

engineering division made perfect sense,”<br />

says Ryan Goodger. “Not only that, but to be<br />

able to respond quickly to customer<br />

demands we need to be confident that we can<br />

locate tools and fixtures quickly, with the<br />

Fami solution we know everything has a<br />

place and everything is in its place. In<br />

addition to the increased efficiency that the<br />

Fami storage from System Store Solutions<br />

gives us, the workshop environment is also<br />

more manageable as it has become second<br />

nature to keep things neat and tidy.”<br />

Tel: 01622 859 522<br />

sales@systemstoresolutions.com<br />

www.systemstoresolutions.com<br />

10 <strong>Machinery</strong> <strong>World</strong>, <strong>July</strong> <strong>2018</strong>

Suppliers of Quality<br />

Used Machine Tools<br />

CINCINNATI V 750 VMC C/W<br />

FANUC<br />

XYZ DPM CNC BED MILL<br />

C/W GUARDING<br />

XYZ VM 3500 CNC MILL<br />

RICHMOND ENVOY<br />

RADIAL ARM DRILL<br />

BUTLER<br />

HYDRABORE<br />

XYZ MINIMILL 560<br />

C/W FANUC CONTROL<br />

HARDINGE TALENT 8/ 52<br />

CNC LATHE<br />

JONES & SHIPMAN 540 GRINDERS<br />

( 5 )<br />

COLCHESTER TORNADO 220M<br />

CNC LATHE<br />

MAZAK VTC 20B VMC<br />

WITH MAZATROL CONTROL<br />

HARRISON ALPHA 330<br />

PLUS 1 MTR B/C<br />

COLCHESTER TRIUMPH 2000<br />

REFURBISHED LATHE<br />

WANTED SURPLUS MACHINES<br />

STARTRITE HB 280<br />

COLCHESTER MASTIFF 80”<br />

FULLY REFURBISHED<br />

HARDINGE TALENT 6/45 CNC<br />

LATHE C/W FANUC CONTROL<br />

1302 JONES & SHIPMAN<br />

GRINDER

NEWS NEWS NEWS<br />

INSPIRATIONAL -<br />

IN SO MANY<br />

WAYS.<br />

Significant leads and enquiry levels gained<br />

from attending Seco’s Inspiration through<br />

Innovation 2017 event motivates Technical<br />

Partner - Matsuura <strong>Machinery</strong> Limited - to<br />

donate £1k to Cancer Research UK - Seco’s<br />

charity of choice.<br />

Seco Tools UK's most recent 'Inspiration<br />

through Innovation' <strong>Manufacturing</strong> Best-<br />

Practice Event, held at the company’s<br />

Technology Centre in Alcester in October<br />

2017, pulled in the crowds (over 700 visitors<br />

over the two days), and cemented its position<br />

and reputation as the ‘go to’ annual event for<br />

UK and Irish component manufacturers.<br />

Inspiration through Innovation 2017 had<br />

something for everyone. The main highlights<br />

included:<br />

• 11 challenging and demanding machining<br />

demonstrations delivered by Seco and a<br />

number of its Technical Partners, that<br />

showcased innovative and advanced<br />

machine tools, tooling technologies,<br />

CAD/CAM software systems, workholding,<br />

metalworking fluids and metrology<br />

solutions;<br />

• Nine best-practice seminars, each led by<br />

an industry expert and each covering, in<br />

some depth, a relevant and topical<br />

manufacturing issue;<br />

• Over 50 Technical Partners each<br />

exhibiting their very latest products, services<br />

and technology solutions to visitors.<br />

In addition, the event was also used by<br />

Seco to promote a number of its own<br />

recently-introduced business solutions and<br />

product innovations from a purpose-built<br />

Seco pavilion - an area specially-designed for<br />

the Open House.<br />

Amongst the Technical Partners attending<br />

the event was leading machine tool supplier<br />

Matsuura <strong>Machinery</strong> Ltd, who used<br />

Inspiration through Innovation 2017 to run a<br />

‘live’ machining demonstration that<br />

showcased the company’s new MX-330 PC10<br />

automated simultaneous 5-axis machining<br />

centre.<br />

Tel: 01789 764220<br />

mike.fleming@secotools.com<br />

www.secotools.com<br />

LONG SERVERS REWARDED<br />

AT WAKEFIELD COMPANY<br />

Group Rhodes, the Wakefield-based<br />

manufacturer, is celebrating the dedication of<br />

a number of its staff, after introducing a 10<br />

year long service award.<br />

Twenty four employees were presented<br />

with a certificate and gift for achieving 10<br />

years+ long service, with one employee,<br />

Gwyn Jones receiving a reward for achieving<br />

a staggering 50 years of service.<br />

Group Rhodes CEO Mark Ridgway said:<br />

“We have rewarded 25 years’ service for<br />

some time and are really pleased to be<br />

introducing our ten year reward to our staff.<br />

Our business relies on retaining talented our<br />

people, so this award is something we feel is<br />

very well deserved. I would particularly like<br />

to thank Gwyn for his significant<br />

contributions over the last five decades. It is<br />

an amazing achievement and we value both<br />

his ongoing knowledge and his role in<br />

passing on his skills to our new recruits.”<br />

Gwyn began as an Apprentice Machinist<br />

working at the company’s Belle Vue base in<br />

Wakefield. He is now a team leader and<br />

helps to mentor new apprentices.<br />

Gwyn Jones said: “I joined the company<br />

as it was one of the best around for training<br />

apprentices. I still enjoy my job and enjoy the<br />

challenge of seeing a project through to its<br />

Customer service has always been a priority<br />

at XYZ Machine Tools from initial sale<br />

through to ongoing support for machine<br />

installations. Recent additions to its service<br />

team bring the numbers of engineers up to 18<br />

and, XYZ has also recognised the expertise of<br />

Julia Aggett who after eight years in the sales<br />

office has been promoted to Customer<br />

Services Manager.<br />

Julia’s promotion is in recognition of her<br />

excellent administration skills that have been<br />

end. It’s also great to be able to help young<br />

apprentices to learn their trade and pass on<br />

my skills to the next generation.”<br />

Group Rhodes is a global manufacturer of<br />

capital equipment, with a product range that<br />

includes hot and cold forming equipment for<br />

metals and composites and machinery used<br />

in the production of heavy ceramics. The<br />

company is also internationally recognised as<br />

a specialist in Superplastic Forming and<br />

Diffusion Bonding for both the aerospace<br />

and automotive industries and offers a full<br />

range of aftermarket services across a wide<br />

range of industrial sectors.<br />

Group Rhodes is made up of a number of<br />

businesses including Rhodes Interform,<br />

Hallamshire Engineering Services and<br />

Craven Fawcett.<br />

www.grouprhodes.co.uk<br />

NEW APPOINTMENTS ENHANCE<br />

CUSTOMER SERVICE FROM XYZ<br />

MACHINE TOOLS<br />

brought to the fore in her sales role over the<br />

past eight years at XYZ Machine Tools. Her<br />

ability to plan and organise a team will be<br />

used to further develop the high levels of<br />

service that XYZ customers already benefit<br />

from. “I am relishing the opportunity to<br />

develop our existing customer support. We<br />

are expanding the service team and making<br />

changes to our way of working to ensure that<br />

we can respond to customer needs in the<br />

shortest possible time” says Julia.<br />

Evidence of this positive effect is the<br />

addition of three new service engineers to the<br />

team with Mark Thorby providing additional<br />

service cover in East Anglia and Cambridge;<br />

Allan Walker working alongside customers<br />

in the South West of England and Wales; and<br />

Jack Roderick extending service coverage in<br />

the North of England. In addition, the team<br />

has also been enhanced with the<br />

appointments of Victoria Hiller and Rebecca<br />

Kemp as Customer Service Representatives<br />

who join the Help Desk team at XYZ’s<br />

headquarters in Devon.<br />

Tel: 01823 674200<br />

nigel.atherton@xyzmachinetools.com<br />

www.xyzmachinetools.com<br />

12 <strong>Machinery</strong> <strong>World</strong>, <strong>July</strong> <strong>2018</strong>

SubconDrillingLtd<br />

Gundrilling - Honing - CNC Machining - Superfinishing<br />

Subcon Drilling Limited is a highly professional<br />

company whose entire experience and energy is<br />

focused solely on Gun Drilling, Deep Hole Drilling,<br />

Honing, CNC Machining and Superfinishing.<br />

With the knowledge and extensive experience<br />

of over 30 years, Subcon Drilling continually<br />

provides a professional and personal approach<br />

with total dedication to quality to a list of long<br />

serving clients.<br />

Our BS EN ISO9001:2008 Quality Management<br />

System is an integral part of our business. Focused<br />

on quality, Subcon Drilling is recognised<br />

as the leading Gun drilling and specialist machining<br />

is recognised as the leading Gun drilling<br />

and specialist machining provider in the U.K.,<br />

continually meeting and exceeding our<br />

customer’s demands.<br />

Subcon Drilling Ltd<br />

Unit 6, The Heron Business Park, Eastman Way, Hemel Hempstead, Hertfordshire HP2 7FW<br />

Tel: 01442 205960 Fax: 01442 205961<br />

www.subcondrilling.co.uk Email: dean@subcondrilling.co.uk<br />

<strong>Machinery</strong> <strong>World</strong>, <strong>July</strong> <strong>2018</strong> 13

NEWS NEWS NEWS<br />

LANTEK MES MANAGER PROVIDES COMPANIES<br />

WITH AN EASY WAY TO TRACE PRODUCTION AND<br />

GET ON THE ROAD TO INDUSTRY 4.0<br />

Implementing Industry 4.0 can seem daunting<br />

for sheet metal companies. However, one of<br />

the industry leader Lantek has some software<br />

tools which provide the first steps, delivering<br />

practical and relevant solutions at an<br />

affordable cost, aimed at producing an<br />

immediate impact on efficiency and customer<br />

satisfaction.<br />

With Lantek MES Manager<br />

manufacturing execution system, engineers<br />

can upload a bill of materials for the products<br />

being manufactured including parts and<br />

subassemblies. Parts are then filtered<br />

according to material type and thickness<br />

ready for nesting in Lantek Expert<br />

CAD/CAM software. At this stage<br />

additional parts from other jobs or<br />

remanufactured parts can be added to the<br />

nest, optimising material utilisation.<br />

Within Lantek MES Manager, the full<br />

sequence of operations required for the<br />

manufacture of each part or subassembly is<br />

stored. This can include for example, laser<br />

cutting, punching, bending, assembly and<br />

painting.<br />

On the shop floor Lantek MES Wos<br />

resides on standard touch screen computers<br />

In June last year, Guhring officially opened<br />

its new 60,000sq/ft £12m manufacturing<br />

facility on Birmingham's Advanced<br />

<strong>Manufacturing</strong> Hub. The new UK<br />

headquarters of the German owned cutting<br />

tool manufacturer was a necessity for the<br />

company to fulfil its future UK growth<br />

ambitions.<br />

For the previous three years, growth had<br />

been constrained by the company being<br />

located on two separate sites that were<br />

crammed to capacity with manufacturing<br />

equipment. Despite the space constraints, it<br />

was two Vollmer PCD erosion machines that<br />

had proven integral to the success of the PCD<br />

tooling department; running efficiently and<br />

productively to keep Guhring ahead of its<br />

increasing order book.<br />

In the 12 months since moving to the new<br />

facility, Guhring has increased staff numbers<br />

by 15% - taking on apprentices in the process.<br />

What is more pertinent is that Guhring UK<br />

previously manufactured 35% of its solid<br />

carbide and PCD product lines in the UK<br />

with the remaining 65% imported from<br />

Germany. Since the factory move, this ratio<br />

has increased to 50% UK manufactured.<br />

Standard product lines and a small quantity<br />

of application specific tooling are imported<br />

or tablets for data capture and to provide<br />

operators with details of the sequence of<br />

manufacturing operations. Links to the<br />

machines record start and finish times for<br />

cutting, while for other tasks employees can<br />

log on to jobs and operations recording the<br />

progress of each part around the workshop<br />

in a paperless environment.<br />

Links back to Lantek MES Manager make<br />

this information available in report form so<br />

that managers can see exactly where parts<br />

are in the production process in real time.<br />

With this live information, companies can<br />

assess and improve the efficiency of<br />

machinery and processes, ensure parts are<br />

delivered on time, quickly detect delays and<br />

from Germany; however January <strong>2018</strong><br />

proved a landmark month with UK<br />

manufactured special tooling sales<br />

outstripping standard product sales for the<br />

first time in Guhring UK’s 40 year history.<br />

The UK manufacturing and re-grinding<br />

divisions of the business have seen sales soar<br />

since the move to the new factory.<br />

Additionally, the installation of a second<br />

coating plant has further underpinned the<br />

company’s strong sales performance.<br />

Integral to the success of the PCD tooling<br />

division at Guhring is its Vollmer QWD750<br />

and QWD750H wire erosion machines.<br />

As Guhring UK’s National Sales Manager,<br />

Mr Dave Hudson says: “The Guhring<br />

cost overruns and provide customers with<br />

accurate information about the progress of<br />

their orders.<br />

For manufacturers with an existing ERP or<br />

sales order processing system, data can be<br />

transferred into and out of Lantek MES<br />

Manager, making use of the investment in<br />

existing technology. However, companies also<br />

have the option of expanding the system with<br />

Lantek’s Integra software. This system<br />

provides wide ranging functionality including<br />

quotation and CRM capabilities, highly<br />

accurate costings, using the intelligence of<br />

Lantek Expert CADCAM, as well as stock<br />

management, documentation and invoicing<br />

and control of multi-site operations.<br />

Taking the first steps towards Industry 4.0<br />

with Lantek MES Manager and Lantek MES<br />

Wos is easy and will deliver traceability and<br />

transparency in manufacturing. Areas for<br />

efficiency improvement will be easier find<br />

and test for effectiveness, customers will be<br />

kept better informed and hence more loyal<br />

and the headache of controlling production<br />

will be a thing of the past.<br />

Tel: +44 (0)1684 342345<br />

rob.powell@lanteksms.com<br />

GUHRING’S PCD TOOLING DIVISION RELIES ON<br />

VOLLMER TECHNOLOGY<br />

manufacturing plant runs 3-shifts for 5 ½<br />

days a week whilst the automation level of<br />

the Vollmer machines in the PCD<br />

department only requires 2-shifts per day.<br />

This labour saving is credit to the Vollmer<br />

machines and our lean manufacturing<br />

processes and workflow scheduling.”<br />

As Mr Hudson says: “Manufacturers<br />

increasingly require multi-function and often<br />

multi-stepped cutting tools to reduce<br />

processes, cycle times and also improve<br />

quality and process stability. This is<br />

particularly true of OEMs and companies in<br />

high-volume environments. To serve these<br />

customers, some special tools will have more<br />

than 18 to 30 PCD segments that are stepped<br />

along the tool shank. The Vollmer QWD<br />

machines are extremely precise and will hold<br />

a 5 micron tolerance in our temperature<br />

controlled building with no problems. This<br />

tight-tolerance capability eliminates tool<br />

grinding processes in many instances. By<br />

eliminating secondary tool grinding, we can<br />

reduce production times; secondary set-up<br />

times and improve the workflow and<br />

throughput of the PCD department.”<br />

Tel: +44 (0)115 9491040<br />

admin-uk@vollmer-group.com<br />

www.vollmer-group.com<br />

14 <strong>Machinery</strong> <strong>World</strong>, <strong>July</strong> <strong>2018</strong>

tuRN suRpLus aNd IdLE assEts<br />

fROM a BuRdEN INtO a BENEfIt!<br />

Wanted used Modern Welding and Cutting <strong>Machinery</strong><br />

Make money on surplus and idle assets quickly and painlessly. Westermans buys and sells single machines and<br />

entire facilities. Take advantage of our worldwide network, unmatched marketing ability, and 50+ years of industrial<br />

welding asset sales experience. As one of the largest and most respected Welding & Cutting sales companies we<br />

offer a variety of solutions to monetise your assets.<br />

Wanted<br />

* aMI, polysoude or Orbimatic tube to tube Orbital welders<br />

* Gullco automated tractors for pipework<br />

* CNC mechanised plasma cutters & modern Oxy-fuel profile<br />

cutters<br />

* Nederman and Lincoln fume extractors<br />

* Welding positioners & pipe Rotators<br />

* submerged arc & Boom welders.<br />

Reward paid<br />

Introduce us to Sellers of modern surplus Welding and CNC<br />

Plasma Cutting Plant and you will be rewarded plus 10%<br />

Commission paid on successful leads.<br />

Why sell to us?<br />

fair price - We know the market and will<br />

always give the best valuation<br />

fast Response - We respond quickly and<br />

our Team will help throughout<br />

Quick payments - Once the deal is agreed<br />

we will pay you promptly<br />

hassle free - We handle inspections,<br />

dismantling and the collection. Easier than<br />

Ebay!<br />

Established Reputation - A family owned<br />

business established for over 50 years<br />

5* Rating - 95% top reviews. Read<br />

comments from our Network and<br />

Customers on Trustpilot.<br />

Investing in a new<br />

Laser Cutter?<br />

Great News…….<br />

We will buy your plasma, waterjet or laser machine<br />

We will pay you MORE than the part exchange deal.<br />

You can then negotiate a good price on your shiny,<br />

new equipment.<br />

fOR a REvIEW Of YOuR<br />

suRpLus MaChINERY aNd a<br />

dIsCussION ON hOW tO tuRN<br />

It IN tO Cash IMMEdIatELY<br />

CONtaCt:<br />

pEtER WEstERMaN<br />

tEL: 0116 298 8636<br />

EMaIL: peter@westermans.com

NEWS NEWS NEWS<br />

hyperMILL ® CAM<br />

STRATEGIES<br />

OPEN MIND will be exhibiting at the<br />

Farnborough International Airshow from 16 to 22<br />

<strong>July</strong> <strong>2018</strong>. On Stand 41660 in Hall 4, the<br />

CAD/CAM developer will present the<br />

hyperMILL® CAM solution for companies in the<br />

aviation and aerospace industry. The leading<br />

software for 5axis machining pushes the limits of<br />

machining centers to meet the special industry<br />

requirements for complex parts and sophisticated<br />

materials. OPEN MIND will provide information<br />

about milling, turning, and HSC, HPC, 2.5D, 3D,<br />

and 5axis machining, as well as process chains<br />

involving PLM and simulations.<br />

OPEN MIND will present proven solutions<br />

for the aviation industry with modules for easy,<br />

secure programming of impeller, blisk, and blade<br />

machining. hyperMILL® also includes many<br />

interesting features for the challenges posed by<br />

other complex parts. These include a range of<br />

innovative 5axis simultaneous strategies that<br />

enable efficient machining of challenging<br />

geometries such as free-form surfaces or deep<br />

cavities. For example, 5axis helical drilling, a<br />

helical tilt milling method in which the milling<br />

tool is tilted in cutting mode, allows holes to be<br />

formed easily and efficiently. A second tilt<br />

prevents collision with the hole wall. This is<br />

advantageous because only one tool is needed for<br />

different drill diameters, or open pockets of<br />

varying sizes. Pre-drilling is not necessary, and<br />

the strategy is very well suited for materials that<br />

are hard to cut.<br />

The hyperMILL® MAXX Machining<br />

performance package is comprised of a set of<br />

machining strategies that are highly popular in<br />

the aerospace industry. Machining strategies in<br />

this package that will be presented at the trade<br />

fair include the extremely efficient finishing of<br />

difficult-to-access surfaces for which OPEN<br />

MIND has developed 5axis tangent plane<br />

machining with conical barrel cutters. This offers<br />

enormous potential for optimization: it takes 90<br />

percent less time than conventional methods.<br />

“Aircraft manufacturers and their suppliers<br />

represent an industry that sets high standards in<br />

terms of innovative materials, machining quality,<br />

and secure processes. At the Farnborough<br />

International Airshow, we will show attendees<br />

how they can use innovative hyperMILL®<br />

strategies to further increase their productivity<br />

and competitiveness,” says Illias Mustafa,<br />

Director Global Accounts, at OPEN MIND<br />

Technologies.<br />

Tel: 01869 290003<br />

Mob: +44 (0) 7867 971 519<br />

adrian.smith@openmind-tech.com<br />

www.openmind-tech.com<br />

ITC INTRODUCES EFFICIENT<br />

MODULAR END MILLING SOLUTION<br />

The Widia VariMill Series has been the end mill of<br />

choice for many Industrial Tooling Corporation<br />

(ITC) customers for a generation; a testament to<br />

the continual evolution of the product line. Now,<br />

Widia has made a radical metamorphosis to the<br />

range that is the mainstay of many machine<br />

shops, integrating the VariMill with the Duo-<br />

Lock modular system.<br />

Convincing customers with its astounding<br />

run-out accuracy, maximum coupling stability<br />

and length repeatability, the tantalising<br />

combination of the VariMill milling technology<br />

and the flexibility of the Duo-Lock system offers<br />

end users a revolutionary new solution. Whilst<br />

the proprietary VariMill geometries allowing<br />

roughing and finishing with a single tool, the<br />

corresponding adaptors include an extensive line<br />

of straight and conical shanks with CV, PSC, BT<br />

and HSK configurations available in Duo-Lock<br />

sizes of DL16, DL20, DL25 and DL32.<br />

The extensive line of modular tools includes<br />

the VariMill, VariMill II, 4547, 4548, 4XN0 and<br />

4X48 high performance series, the 4U40 45 degree<br />

roughing series, the 4969 ball nose roughing<br />

series, 5748 VariMill II ER, 774E VariMill III ER<br />

Series, the 5142 and 5143 AluSurf line, the 8045<br />

Corner Rounding line and the 8046 Corner<br />

Chamfering series. Each of these industry leading<br />

solutions include a tapered core that<br />

demonstrates astounding stability and an<br />

eccentric relief design that increases tool life<br />

through higher edge stability.<br />

Many of the modular heads are available with<br />

diameters that include 10, 12, 16, 20, 25 and 32mm<br />

with a length of cut from 15 to 48mm depending<br />

upon the chosen end mill designation. The<br />

extremely diverse range of heads and the<br />

comprehensive dimensional and geometrical<br />

offerings now provide manufacturers with a cost<br />

effective, highly productive solution that<br />

significantly reduces set-ups and tool<br />

changeovers with the high repeatability modular<br />

design.<br />

Furthermore, the high-quality solid carbide<br />

Widia VariMill modular heads are offered as<br />

AlTiN coated and uncoated grades. This<br />

proposes the most productive machining solution<br />

on a complete spectrum of materials. With the<br />

new Duo-Lock and VariMill combination, Widia<br />

and ITC are introducing the most cost-effective<br />

milling range for machining everything from<br />

aluminium and steel through to difficult to<br />

machine high temperature alloys. For further<br />

details on how the Widia Duo-Lock system can<br />

revolutionise your performance and inventory<br />

management, please contact ITC.<br />

Tel: 01827 304500<br />

sales@itc-ltd.co.uk<br />

www.itc-ltd.co.uk<br />

BE A WINNER AT THE<br />

XYZ SLOUGH OPEN HOUSE<br />

Visitors to the opening event at XYZ Machine<br />

Tools new showroom in Slough on the 12th <strong>July</strong><br />

will be able to join in the celebrations with the<br />

opportunity to win the use, on loan, of either a<br />

ProtoTRAK SMX 2000 Turret Mill, an SMX 2500<br />

Bed Mill or a ProTURN SLX 1630 lathe for six<br />

months.<br />

Every company represented at the open house<br />

will be entered in the draw with the winner<br />

receiving either one of the ProtoTRAK turret and<br />

bed mills or the ProTURN lathe on offer (alternate<br />

machines may be available). The machine will be<br />

delivered and commissioned, and the successful<br />

company will also receive the usual allocation of<br />

training from XYZ Machine Tools to maximise<br />

the benefit of the prize. They will then have full<br />

use of the machine for six months, the equivalent<br />

of 1000 hours of free CNC production. At the end<br />

of the loan period the machine can be collected or,<br />

an order can be placed to keep it. Of course, any<br />

visitor that places an order for a ProtoTRAK or<br />

ProTURN machine on the day, only to be<br />

declared the winner, arrangements will be made<br />

so that they too can benefit from the draw.<br />

While there can only be one winner of the<br />

prize draw, there will still be other winners with<br />

machine offers on the day. “As this is a brandnew<br />

showroom we won’t be offering clearance<br />

deals on the machines in Slough, but there will be<br />

a list available of all the clearance machines at our<br />

other showrooms at Burlescombe, Nuneaton,<br />

Blackburn and Sheffield, with visitors to the<br />

Slough event having first refusal on these with<br />

preferential prices to our guests on the day,” says<br />

Nigel Atherton, Managing Director, XYZ<br />

Machine Tools.<br />

Anyone wishing to attend the showroom<br />

open day at 944 Yeovil Road, Slough, SL1 4NH is<br />

asked to e-mail XYZ Machine Tools at<br />

sales@xyzmachinetools.com in order that<br />

numbers can be managed for catering purposes.<br />

Tel: 01823 674200<br />

nigel.atherton@xyzmachinetools.com<br />

www.xyzmachinetools.com<br />

16 <strong>Machinery</strong> <strong>World</strong>, <strong>July</strong> <strong>2018</strong>

Supplying New & Used Machines since 1951<br />

Quality Machines | Quality Service | Quality Assured<br />

AVAILABLE FROM STOCK:<br />

LAGUN BS4 Bed Type Mill<br />

4000 x 1200 x 1500mm travels.<br />

Heidenahin TNC640 control<br />

AVAILABLE FROM STOCK:<br />

LAGUN BM4 & BM5 Bed Type Mill<br />

4000 / 5000 x 1200 x 1500mm travels.<br />

Heidenahin TNC640 control<br />

LAGUN BS Series Bed Type Milling Machines<br />

AVAILABLE FROM STOCK - LAGUN BS4<br />

Equipped with:<br />

• HEIDENHAIN TNC640 CNC control<br />

• Automatic head with 2.5deg indexing (144 x 144 positions)<br />

• Simple guarding<br />

• 4000rpm spindle<br />

• 20bar Thru Spindle Coolant<br />

• 24 station ATC<br />

LAGUN BM Series Bed Type Milling Machines<br />

with increased Y / Z travels<br />

AVAILABLE FROM STOCK - LAGUN BM4 & BM5<br />

Equipped with:<br />

• HEIDENHAIN TNC640 CNC control<br />

• Automatic head with 2.5deg indexing (144 x 144 positions)<br />

• Simple guarding<br />

• 4000rpm spindle<br />

• 20bar Thru Spindle Coolant<br />

• 24 station ATC<br />

LAGUN TM Series with unique XYZ and V Axis<br />

travels for large capacity machining<br />

Cross Moving Column T Type Milling Machines<br />

• 1500 x 1500mm table with 10,000Kg load<br />

• X axis of 2000 / 3000 / 4000mm<br />

• 1200mm Y axis<br />

• 1500mm Z axis with 2000mm option<br />

• V axis with 1000mm or 1500mm option allowing<br />

components upto 2500mm diameter to be machined<br />

within a compact oorspace<br />

LAGUN CM Series of Travelling Column type<br />

machines with upto 12,000mm travels<br />

Travelling column milling machines with a xed<br />

table.<br />

• From 4000mm to 12,000mm X axis travels<br />

• Y axis travels of 1200mm with 1300mm option<br />

• Z Axis travels of 1500mm with a 2000mm option<br />

• Table loads of upto 6000Kg/m 2<br />

• Wide range of Millng machine heads including<br />

2.5deg, 1.0deg, 0.003deg indexing & high speed<br />

Turning | Milling | Grinding | Drilling | EDM<br />

Thread Rolling | Sawing | Sheetmetal<br />

With more than 60 years experience,<br />

LAGUN manufacture a full series of milling<br />

machines from the traditional bed-type<br />

machine to the most innovative highperformance<br />

milling machines.<br />

Tel:<br />

Email:<br />

Web:<br />

Twitter:<br />

+44(0) 1322 447611<br />

sales@rk-int.com<br />

www.rk-int.com<br />

@rkimachinetools

NEW PRODUCTS – NEW PRODUCTS – NEW PRODUCTS<br />

SICK LAUNCHES PLUG-AND-PLAY<br />

‘SNAPSHOT’ SENSOR<br />

SICK has launched a configurable, plug-andplay<br />

3D detection sensor based on its<br />

Visionary-T range of industrial 3D imaging<br />

cameras, harnessing the imaging power of<br />

SICK’s single-snapshot Time-of–Flight (TOF)<br />

technology for a range of detection and<br />

collision warning duties.<br />

With on-board processing, the Visionary-<br />

T DT sensor can be easily configured for a<br />

variety of applications to detect the presence<br />

or absence of 3D objects. It therefore offers a<br />

versatile, entry-level option for collision<br />

warning on forklifts, Automated Guided<br />

Vehicles (AGVs) and Carts (AGCs).<br />

Tasks that were previously difficult to<br />

achieve with a fixed camera are now quickly<br />

and easily accomplished by the Visionary-T<br />

DT, for example to detect whether a bin, tote<br />

German tooling manufacturer, Horn, has<br />

introduced two grooving systems for internal<br />

machining of bores. System 209 is intended<br />

for bores of diameter 16 mm and above,<br />

while system 216 machines bores greater<br />

than or equal to 20 mm diameter.<br />

Both systems utilise toolholders with<br />

internal cooling. A robust shank with<br />

elliptical cross-section of the boring bar neck<br />

ensures excellent damping properties. The<br />

ground shanks, of g6 quality, are available in<br />

left-hand or right-hand design.<br />

Coolant flows from a nozzle in the<br />

clamping finger and from the side of the tool<br />

holder. The two jets cool the cutting zone<br />

effectively and remove chips from the inside<br />

of the workpiece in a controlled, efficient<br />

manner.<br />

Precision-sintered, indexable, two-edged<br />

inserts with cutting widths from 2 to 6 mm<br />

are available in geometries .5, .1A and .KF for<br />

cutting medium strength materials. All three<br />

geometries offer good chip control and<br />

targeted chip breaking, even on longchipping<br />

materials.<br />

or stillage is completely empty, part full, or<br />

overloaded.<br />

The sensor provides 3D image analysis<br />

with a simple yes/no, occupied or<br />

unoccupied, signal depending on the<br />

configuration. A discrete output signal<br />

enables easy integration with an automated<br />

system. Direct communication capability can<br />

be set up to a visual display, an acoustic<br />

alarm or a PC, and to enable activity<br />

recording for later appraisal of any incidents.<br />

The Visionary-T DT can assess the<br />

availability of a workstation or cell on a<br />

production line where a large object, such as<br />

a vehicle or other machinery assembly, is to<br />

be moved for the next phase and warn of any<br />

intrusions.<br />

SICK’s Visionary-T imaging sensors<br />

capture high-resolution real-time 3D images<br />

with one shot of light, dispensing with the<br />

need to profile a moving object through laser<br />

triangulation. The SICK single-snapshot<br />

technology does not need movement to<br />

create the depth of field and object resolution<br />

required for high-performance 3D detection.<br />

The Visionary-T DT can be configured<br />

using a PC, SICK’s SOPAS software tool and<br />

a purpose-designed Graphical User Interface.<br />

3D objects or detection zones can be taught<br />

from the camera without the need for<br />

complex programming.<br />

Tel: 01727 831121<br />

andrea.hornby@sick.co.uk<br />

NEW INTERNAL GROOVING SYSTEM<br />

The 209 system toolholders with a shank<br />

diameter of 16 mm allow retraction distances<br />

of up to 30 mm in conjunction with a<br />

grooving depth of 3.5 mm. For bores with a<br />

diameter of 18 mm or above, a more stable<br />

shank diameter of 20 mm, also with a<br />

retraction distance of 30 mm, can be used to<br />

achieve a grooving depth of 5 mm. The 216<br />

system toolholders, with a shank diameter of<br />

20 or 25 mm, enable grooving depths down<br />

to 7 mm at a projection length of 2 x D.<br />

mikegreen@phorn.co.uk<br />

www.phorn.co.uk<br />

SUMITOMO<br />

OVERCOMES<br />

PROBLEMS<br />

Sumitomo Electric Hardmetal has developed<br />

a new style GS chipbreaker that overcomes<br />

problems and improves control of the<br />

process when milling deep shoulders and<br />

slots involving up to 6 mm depth-of-cut on<br />

components using its SEC-Sumi Dual Mill<br />

(DFC) Type cutter body range.<br />

When successfully introduced two years ago,<br />

the DFC Type Dual Mill was a breakthrough<br />

in cutter body and insert design. The XNMU<br />

inserts bring new levels of economics in<br />

reduced costs as they are available as doublesided<br />

inserts with six corners.<br />

With the addition of GS to the existing<br />

XNMU series of three chipbreaker inserts<br />

this specifically accommodates deeper<br />

cutting situations up to 6 mm in steel and<br />

cast iron. The existing chipbreakers were<br />

targeted at L for light milling, G for general<br />

purpose and H for roughing as well as heavy<br />

interrupted cuts plus hard steel milling. The<br />

cutting edge of the GS chipbreaker is set at 25<br />

deg with a range of corner radii between 0.4<br />

mm and 1.6 mm. The cutting edge enhances<br />

the toughness of the insert which also<br />

incorporates a wiper edge that helps to<br />

optimise machining accuracy and surface<br />

finish.<br />

The new cutter body and insert<br />

development of DFC capitalised on the<br />

benefits of higher security and accuracy of<br />

index by separating the location area from<br />

the cutting edge so that it is able to match the<br />

machining accuracy of single-sided inserts.<br />

It also provided higher stability under cut<br />

and especially when high, optimised feed<br />

rates are involved.<br />

DFC Type Dual Mill spans shank bodies<br />

in standard and fine pitch between 25 mm<br />

and 80 mm diameter with between two and<br />

seven teeth. Shell mill cutters are in<br />

standard, fine and extra fine pitch between 50<br />

mm and 160 mm diameter and with between<br />

four and 16 teeth.<br />

Tel: 01844 342081<br />

www.sumitomotool.com<br />

18 <strong>Machinery</strong> <strong>World</strong>, <strong>July</strong> <strong>2018</strong>

Tel : +44 (0) 161 330 4242<br />

Fax + 44 (0) 161 343 1347<br />

Email : Sales@newcentury.co.uk<br />

www.newcentury.co.uk<br />

Unit 2 Riverside Industrial<br />

Estate,<br />

Margaret Street,<br />

Ashton-under-lyme.<br />

Lancashire. OL7 0QQ<br />

Amada LC-1212 III laser cutting machine,<br />

Refurbished by Amada UK 2016, Radan<br />

software, 2000w , laser output, 1270 x 1270<br />

x 300mm axis traverse, Fanuc CNC, 14300<br />

power on hours. £POA<br />

Geminis GE-1200-S Oil country lathe, Digital<br />

read out, coolant, steady, 412mm spindle<br />

bore, spindle speeds to 710rpm, 1260mm<br />

swing over bed, 2m b/c. £POA<br />

Colchester Multiturn 2000 CNC lathe, New<br />

2004, Fanuc OI-TB CNC, 3 jaw chuck,<br />

coolant, speeds to 2700rpm, Sauter<br />

indexing turret, 400 x 1250mm capacity.<br />

£POA<br />

Harrison Alpha 400T CNC lathe, Fanuc<br />

touch screen CNC, 400mm swing, 585mm<br />

in gap, 1250mm between centres, speeds to<br />

2500rpm, 54mm spindle bore. £POA<br />

Quaser MV204II vertical machining centre,<br />

Siemens 810D, BT 40, speeds to 7500rpm,<br />

32 station ATC, 1200 x 635mm table,<br />

X=1020 Y=600 Z=560mm capacity. £POA<br />

Safan VS 310-6 hydraulic guillotine, Rear<br />

sheet support, power backgauge, squaring<br />

arm, supports 40 strokes per minute, 3100 x<br />

6mm capacity. £POA<br />

Amada HFE 80 – 25 CNC press brake, New<br />

2006, OP 2000 CNC 7 axis, 200mm stroke,<br />

420mm throat, light guards, handwheel,<br />

75mm bed width, 80tons x 2570mm. £POA<br />

Charmilles 310 Robofil wire eroder, Hand<br />

control, auto wire feed, 850 x 500 x 400mm<br />

max work piece dimensions, X=400 Y=250<br />

Z= 400mm, 30 degree taper cut. £POA<br />

Tel: +44 (0) 161 330 4242 Fax: +44 (0) 161 343 1347<br />

Email: hq@newcentury .co.uk Website: www.newcentury.co.uk<br />

TOP QUALITY MACHINERY<br />

www.newcentury.co.uk<br />

MYFORD<br />

MG12 Series Grinders<br />

JONES & SHIPMAN<br />

Grinders<br />

PG Optidress<br />

Diaform<br />

Spares and Accessories<br />

WANTED: PG OPTIDRESS E Attachment<br />

JUBILEE MACHINE TOOLS<br />

T: 01332 348749 www.jubileemactools.com F: 01332 342416<br />

<strong>Machinery</strong> <strong>World</strong>, <strong>July</strong> <strong>2018</strong> 19

NEW PRODUCTS – NEW PRODUCTS – NEW PRODUCTS<br />

RAINFORD<br />

PRECISION<br />

INTRODUCE HIGH<br />

ACCURACY END<br />