150H Fork Positioner - Cascade Corporation

150H Fork Positioner - Cascade Corporation

150H Fork Positioner - Cascade Corporation

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

I<br />

NSTALLATION<br />

2.1 Truck System<br />

Requirements<br />

The <strong>150H</strong> <strong>Fork</strong> <strong>Positioner</strong> will provide maximum operating<br />

capability when the following requirements are met.<br />

A<br />

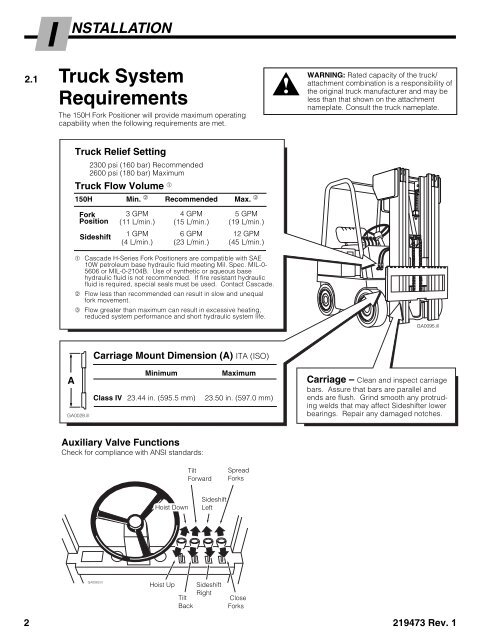

Truck Relief Setting<br />

GA0028.ill<br />

2300 psi (160 bar) Recommended<br />

2600 psi (180 bar) Maximum<br />

Truck Flow Volume ➀<br />

<strong>150H</strong> Min. ➁ Recommended Max. ➂<br />

<strong>Fork</strong><br />

3 GPM 4 GPM 5 GPM<br />

Position<br />

(11 L/min.) (15 L/min.) (19 L/min.)<br />

Sideshift<br />

1 GPM<br />

(4 L/min.)<br />

6 GPM<br />

(23 L/min.)<br />

12 GPM<br />

(45 L/min.)<br />

➀ <strong>Cascade</strong> H-Series <strong>Fork</strong> <strong>Positioner</strong>s are compatible with SAE<br />

10W petroleum base hydraulic fluid meeting Mil. Spec. MIL-0-<br />

5606 or MIL-0-2104B. Use of synthetic or aqueous base<br />

hydraulic fluid is not recommended. If fire resistant hydraulic<br />

fluid is required, special seals must be used. Contact <strong>Cascade</strong>.<br />

➁ Flow less than recommended can result in slow and unequal<br />

fork movement.<br />

➂ Flow greater than maximum can result in excessive heating,<br />

reduced system performance and short hydraulic system life.<br />

Carriage Mount Dimension (A) ITA (ISO)<br />

Auxiliary Valve Functions<br />

Check for compliance with ANSI standards:<br />

GA0082.ill<br />

Minimum Maximum<br />

Class IV 23.44 in. (595.5 mm) 23.50 in. (597.0 mm)<br />

Hoist Down<br />

Hoist Up<br />

Tilt<br />

Back<br />

Tilt<br />

Forward<br />

Sideshift<br />

Left<br />

Sideshift<br />

Right<br />

Spread<br />

<strong>Fork</strong>s<br />

Close<br />

<strong>Fork</strong>s<br />

WARNING: Rated capacity of the truck/<br />

attachment combination is a responsibility of<br />

the original truck manufacturer and may be<br />

less than that shown on the attachment<br />

nameplate. Consult the truck nameplate.<br />

GA0095.ill<br />

Carriage – Clean and inspect carriage<br />

bars. Assure that bars are parallel and<br />

ends are flush. Grind smooth any protruding<br />

welds that may affect Sideshifter lower<br />

bearings. Repair any damaged notches.<br />

2 219473 Rev. 1