20180903_tf_2_2018_BeilegerImHeft_enGB_RZ_Einzelseiten_epaper

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ENERGY MANAGEMENT<br />

PERFECTION<br />

The new Coating Centre saves a lot of energy in the coating process of a trailer chassis, as innovative technologies are being used to<br />

avoid waste heat and to utilise what has been created. It has already received an award from the German Energy Agency prior to<br />

commissioning for this, as well as further efficiency measures in all processes.<br />

The German Energy Agency (Dena) has<br />

awarded the new Coating Centre from Krone<br />

as a pioneering project for the reduction<br />

of waste heat. Krone uses state-of-the-art<br />

production technologies to significantly reduce CO 2<br />

emissions: by around 40 percent. “We’ve achieved<br />

this outstanding result primarily through the intelligent<br />

combination of various efficiency measures in<br />

this design,” explained Mathias Schrigten, the industrial<br />

engineer at Krone responsible for the waste heat<br />

concept of the Coating Centre.<br />

Where possible, heat loss within the Coating Centre<br />

is avoided or recycled for use elsewhere within the<br />

plant. The new building enables the responsible use<br />

of resources and sustainable operation of the entire<br />

industrial plant.<br />

HEAT USE FROM PASSIVE COOLING<br />

In order to achieve the desired results when blasting<br />

the surfaces, the workpieces must be supplied to<br />

the blasting system dry and heated to room temperature.<br />

For this purpose, the heat emitted to the ambient<br />

air by the chassis during cathodic dip painting<br />

(CDP) and powder cooling is fed to the raw chassis<br />

buffer. The blasting system is also designed so that<br />

the exhaust air, which is heated and filtered during the<br />

process, flows back through the building. Highly efficient<br />

drives and turbines, as well as high-performance<br />

filters, are used to reduce pressure loss.<br />

A heat exchanger installed at the thermal oxidiser<br />

(TO) ensures that the heat generated during the<br />

cleaning process of the CDP furnace exhaust air<br />

heats the process tanks in the bath station. The powder<br />

furnace also produces waste heat, for example,<br />

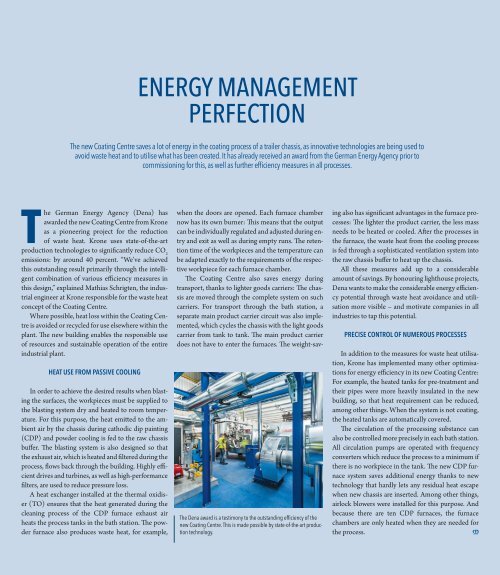

The Dena award is a testimony to the outstanding efficiency of the<br />

new Coating Centre. This is made possible by state-of-the-art production<br />

technology.<br />

when the doors are opened. Each furnace chamber<br />

now has its own burner: This means that the output<br />

can be individually regulated and adjusted during entry<br />

and exit as well as during empty runs. The retention<br />

time of the workpieces and the temperature can<br />

be adapted exactly to the requirements of the respective<br />

workpiece for each furnace chamber.<br />

The Coating Centre also saves energy during<br />

transport, thanks to lighter goods carriers: The chassis<br />

are moved through the complete system on such<br />

carriers. For transport through the bath station, a<br />

separate main product carrier circuit was also implemented,<br />

which cycles the chassis with the light goods<br />

carrier from tank to tank. The main product carrier<br />

does not have to enter the furnaces. The weight-saving<br />

also has significant advantages in the furnace processes:<br />

The lighter the product carrier, the less mass<br />

needs to be heated or cooled. After the processes in<br />

the furnace, the waste heat from the cooling process<br />

is fed through a sophisticated ventilation system into<br />

the raw chassis buffer to heat up the chassis.<br />

All these measures add up to a considerable<br />

amount of savings. By honouring lighthouse projects,<br />

Dena wants to make the considerable energy efficiency<br />

potential through waste heat avoidance and utilisation<br />

more visible – and motivate companies in all<br />

industries to tap this potential.<br />

PRECISE CONTROL OF NUMEROUS PROCESSES<br />

In addition to the measures for waste heat utilisation,<br />

Krone has implemented many other optimisations<br />

for energy efficiency in its new Coating Centre:<br />

For example, the heated tanks for pre-treatment and<br />

their pipes were more heavily insulated in the new<br />

building, so that heat requirement can be reduced,<br />

among other things. When the system is not coating,<br />

the heated tanks are automatically covered.<br />

The circulation of the processing substance can<br />

also be controlled more precisely in each bath station.<br />

All circulation pumps are operated with frequency<br />

converters which reduce the process to a minimum if<br />

there is no workpiece in the tank. The new CDP furnace<br />

system saves additional energy thanks to new<br />

technology that hardly lets any residual heat escape<br />

when new chassis are inserted. Among other things,<br />

airlock blowers were installed for this purpose. And<br />

because there are ten CDP furnaces, the furnace<br />

chambers are only heated when they are needed for<br />

the process.

ANDREAS SCHEUER AND<br />

BERNARD KRONE PULL<br />

THE LEVER<br />

The new coating centre in Werlte was officially opened in August.<br />

As part of the "Krone Future Lab", Bernard Krone, Managing Partner<br />

of the Krone Commercial Vehicle Group, and Federal Minister of<br />

Transport Andreas Scheuer, symbolically pull the lever for the start<br />

of the system. Among the guests were more than 400 customers of<br />

Krone, who have trusted the quality of the company for a long time.<br />

This video shows<br />

some aspects<br />

of the opening<br />

event.

SPECIAL EDITION<br />

SURFACE COATING<br />

IN A NEW DIMENSION<br />

State-of-the-art, tried-and tested coating technology coupled with a fully automatic chassis warehouse.<br />

Perfect surface coating for maximum protection<br />

against corrosion: The Krone<br />

Commercial Vehicle Group offers its customers<br />

state-of-the-art, tried-and-tested<br />

coating in combination with innovative automation<br />

technology at the new Coating Centre in Werlte.<br />

The goal: Highest quality in order for customers<br />

to have the best vehicles to meet the challenges of<br />

their business.<br />

The new coating plant, which took 13 months<br />

to construct, is located in a facility measuring 120<br />

by 130 metres and up to 20.5 meters high. An area<br />

of 16,500 square metres provides ample space for<br />

the Coating Centre to include an integrated, fullyautomated<br />

chassis warehouse. The chassis are coated<br />

in the plant using a tried-and-tested coating concept:<br />

The cathodic dip painting (CDP) with final<br />

»We are bringing the<br />

Werlte site up to the<br />

highest technical level<br />

of industrialisation<br />

currently possible.«<br />

Bernard Krone<br />

powder coating makes the vehicle highly wear-resistant.<br />

The plant is designed for a maximum<br />

weight capacity of four tons and accepts raw parts<br />

of all types.<br />

“The new coating plant brings the Werlte site<br />

up to the highest technical level of industrialisation<br />

currently possible,” explained Bernard Krone,<br />

Managing Partner of the Krone Commercial Vehicle<br />

Group.<br />

At 40 million euros, this is the greatest<br />

single investment in the company’s history. This is a<br />

clear commitment to the site, to sustainable quality<br />

– and to protection of the environment: The Coating<br />

Centre meets the latest requirements, and CO 2<br />

emissions<br />

per coated chassis are reduced. The exhaust gas<br />

from the baking furnaces is also thermally treated,<br />

which greatly reduces odour emissions.

»WE HAVE SET OURSELVES HIGH GOALS<br />

AND HAVE ACHIEVED THEM TOGETHER«<br />

Volker Perk, Head of Industrial Engineering of the Krone Commercial Vehicle Group, described the philosophy and<br />

technical masterpiece that is anchored in the heart of the new Coating Centre at the Werlte site.<br />

Since the beginning of July, the first chassis have<br />

already been manufactured in trial operation at<br />

the new Coating Centre. What does this mean to<br />

you personally?<br />

I'm really glad that we were able to do so much together<br />

as a team. Together, we have set ourselves high goals and<br />

achieved them consistently ahead of schedule! All those<br />

involved have invested a great deal of energy over the<br />

past year and a half and have ensured that all our ideas<br />

have been implemented and all requirements met. The<br />

construction was also completed without impairing<br />

further production processes. This was a really special<br />

achievement. We were also able to smoothly inte grate<br />

the new processes with the corresponding interfaces.<br />

And the topics, 'quality' and 'sustainability' were always<br />

of utmost importance in all of this. For me, the new<br />

Coating Centre perfectly embodies the quality concept<br />

for which the Krone company stands.<br />

Why did Krone invest in such a modern Coating<br />

Centre?<br />

We wanted to set new standards for coating our chassis<br />

in terms of quality, corrosion protection and sustainability<br />

in regard to environmental protection and energy<br />

efficiency. The centre allows state-of-the-art automatic<br />

control of the entire coating process. Colouring and<br />

assembly are decoupled: This ensures the optimum sequence<br />

of coating and assembly.<br />

What distinguishes the systems, especially in the<br />

light of future challenges?<br />

The high level of automation! It enables maximum reliability<br />

and also takes the pressure out of the shortage of<br />

skilled workers – high quality production is assured. A<br />

dynamic, fully automatic warehouse is integrated into<br />

the coating system with the sequencer, via which the<br />

products can be appropriately introduced into each processing<br />

stage up to delivery to the assembly department.<br />

»The topics Quality<br />

and Sustainability<br />

are always at the top of<br />

the planning and<br />

implementation agenda.«<br />

Volker Perk<br />

Modern conveyor technology in combination with central<br />

process automation ensures that all processes are<br />

optimally controlled and implements all movements of<br />

the chassis within the Coating Centre. All programs are<br />

generated and processed automatically using object dependencies.<br />

Each processing step is digitally monitored<br />

accordingly and logged.<br />

In what way is perfect corrosion protection guaranteed?<br />

We prepare the workpieces optimally so that the paint<br />

adheres seamlessly and firmly. The complete chassis is<br />

first cleaned and descaled by 3D blasting. The combination<br />

of splash, spray and immersion degreasing also<br />

contributes to this, as well as zinc phosphating with subsequent<br />

passivation. The CDP dip coating belongs to a<br />

series that has been optimally designed for corrosion<br />

protection. It has a special edge protection additive that<br />

provides better protection for every edge of the chassis<br />

through thicker layers. After thermal crosslinking<br />

at around 190 degrees Celsius, a homogeneous, diffusion-tight<br />

film coating is produced that reliably keeps<br />

environmental influences away from the substrate. The<br />

system is immersed in water and contains less than two<br />

percent residual solvent. In addition, the powder coating<br />

process is highly automated, thus we can meet all<br />

the customers' colour requirements. Last but not least,<br />

state-of-the-art furnace technology plays its part in ensuring<br />

that we can provide the best protection against<br />

corrosion.<br />

How do you deal with the areas of the chassis are<br />

particularly difficult to reach?<br />

In complex simulation runs, we have designed the blasting<br />

machine so that the steel blasting material reaches<br />

the workpiece right to the last corner. It is optimally<br />

prepared for the coating: The combination of splash,<br />

spray and immersion degreasing ensures a completely<br />

clean and dust-free chassis – the optimum basis for the<br />

further coating process. Zinc phosphate reacts directly<br />

with the chassis material, and the CDP ensures that the<br />

chassis is coated uniformly, even in cavities and on intricate<br />

parts of the structure.<br />

What role has environmental protection played in<br />

the design of the centre?<br />

It was very important to us to protect the environment<br />

as much as possible and to use all resources responsibly.<br />

We were able to achieve this through intensive planning,<br />

and we have reached a new level of efficiency with<br />

these systems.<br />

Are there already next steps or goals?<br />

First of all, we are pleased to be able to offer our customers<br />

future-proof surface protection for their vehicles. Of<br />

course, we are constantly improving, and there will certainly<br />

be more exciting projects in the coming months<br />

and years – both small and large.

1<br />

reach almost all surfaces of the chassis construction. During<br />

the blasting process, about 25 tons of the steel blasting<br />

material is fired at the chassis at a speed of up to 300 kilometres<br />

per hour. Falling blasting material is fed back to the<br />

process via screw conveyors.<br />

3<br />

RAW CHASSIS BUFFER<br />

The raw chassis are delivered in packages of four to the<br />

Coating Centre. The vehicles can pass through the delivery<br />

hatch with no need for difficult manoeuvres.<br />

The buffer zone offers storage space – here, the individual<br />

chassis wait to be guided through the system. One step<br />

follows another like a string of pearls: A precisely planned,<br />

timed and automated process. The conveyor system takes<br />

over the raw chassis at a binding station with two overhead<br />

cranes.<br />

The plant uses the warm air from the cooling areas in the<br />

coating process to ensure that the supplied chassis are heated<br />

to room temperature and transferred dry into the further<br />

process steps. A ventilation system directs this air directly to<br />

the raw chassis buffer.<br />

2<br />

BLASTING SYSTEM WITH<br />

DE-SANDING STATION<br />

The first station that each chassis must pass through involves<br />

blasting and de-sanding: Because the chassis are delivered<br />

raw, the metal is precision shot-blasted using steel<br />

balls. This removes mill scale, cinder and impurities, resulting<br />

in a clean, bright, metallic surface with the pre-treatment<br />

and the CPD coating can optimally adhere to later.<br />

The blast system is equipped with 22 turbines – more than<br />

twice as many as in the previous system. This enables an<br />

optimal blasting result to be achieved. The intelligent arrangement<br />

supports this goal: The turbines are arranged<br />

three-dimensionally in the blasting chamber so that they<br />

After the treatment, many steel balls remain on the chassis<br />

and in cavities. The chassis is cleared of these at the desanding<br />

station: To do this, it is fixed to a device that moves<br />

it around its own axis several times with turning and tilting<br />

movements. What remains is a cleaned chassis with a clean,<br />

bare metallic surface.<br />

4<br />

DIPPING LINE<br />

The chassis is pre-treated in the tank stations and then<br />

CDP-coated. After a testing period, during which more than<br />

1,000 metal sheets and test pieces were used, KRONE has<br />

opted for tri-cationic zinc phosphating – the best-proven<br />

technology currently available.<br />

The system can be operated in three shifts: In the pre-treatment,<br />

the chassis is immersed in different tanks one after<br />

the other. The baths are circulated around the clock to keep<br />

bath parameters such as pH constant. The parameters are<br />

continuously checked. Each chassis passes through the following<br />

stations within approximately 90 minutes:<br />

A) Splash and spray degreasing: The chassis is mechanically<br />

cleaned. As it enters the spray degreasing tank, it<br />

is rinsed off and then sprayed with a large number of<br />

nozzles while moving continuously.<br />

<br />

B) Immersion degreasing baths and rinsing: In this<br />

station, the chassis is carefully cleaned and degreased<br />

again. Baths with special liquids are used for this purpose.<br />

The metal is dipped twice in the immersion<br />

degreasing baths and the rinsing tanks.<br />

C) Preparation of the surface for a flawless CDP coating:<br />

Zinc phosphating is carried out before the actual<br />

coating by cathodic dip painting. This is a chemical process<br />

that prepares the material optimally for absorption<br />

of the paint. It is immersed in an acidic solution<br />

which triggers the desired reaction with the metal.<br />

Zinc phosphating increases the adhesion of the coating<br />

and protects against corrosion. The chassis is then<br />

rinsed twice more before a passivation bath completes<br />

the zinc phosphating process to perfection: As a result,<br />

the surface is completely and evenly sealed again. This<br />

is followed by a further rinse in demineralised water.<br />

D) CDP coating: The final seal of the chassis takes place<br />

in a tank containing the CDP-coating. When immersed,<br />

the CDP coating preparation reaches even the smallest<br />

cavities to ensure an even and effective coating of the<br />

metal. The CDP coating is applied to the surface of the<br />

chassis at over 300 volts DC and around 2,300 amps.<br />

The components are then rinsed twice more, removing<br />

any excess paint.

9<br />

Buffer zones<br />

1st Floor<br />

9<br />

8<br />

8<br />

Powder furnaces<br />

Delivery<br />

A BRILLIANT<br />

PERFORMANCE<br />

ALL ALONG THE LINE<br />

1<br />

Raw chassis buffer<br />

1<br />

The raw chassis undergo a highly automated coating process for<br />

optimum sealing in the Krone Coating Centre, where energy efficiency,<br />

durability and the highest quality are combined.<br />

2<br />

Blasting system

7<br />

Powder chambers<br />

6<br />

Buffer zones<br />

5<br />

CDP furnaces<br />

Ground Floor<br />

6<br />

Transfer<br />

to assembly<br />

Pre-assembly<br />

7<br />

5<br />

10<br />

4<br />

3<br />

2<br />

4<br />

Dipping Line<br />

3<br />

Desanding

5<br />

CDP FURNACES<br />

The coating must be dried. For this purpose, the plant has<br />

ten large CDP furnaces, which are heated to a defined<br />

temperature of around 190 degrees Celsius. In this process,<br />

the CDP coating is firmly bonded to the surface of<br />

the chassis. Depending on the type of chassis, this takes<br />

about 40 to 60 minutes. The coating crosslinks to form a<br />

homogeneous, closed film that will effectively protect the<br />

component in future applications. Outdoor air is used to<br />

cool it down. A thermal oxidiser is used to clean the exhaust<br />

air from the furnaces.<br />

6<br />

9<br />

BUFFER ZONES<br />

Here, the chassis cool down passively and are then stored<br />

until they continue into the powder coating. In this step,<br />

the customer can choose their own colour scheme: All RAL<br />

colours are available. The desired colour is applied in one<br />

of the two powder chambers in the system – the powder<br />

system is changed accordingly for each new colour. Since<br />

process automation determines the coating sequence, the<br />

system automatically detects when a colour change is due<br />

and initiates the changeover in the powder chambers. The<br />

chassis can be stored dynamically via transfer bridges. This<br />

makes it possible to optimise colour changes – for maximum<br />

efficiency and to create as little waste as possible.<br />

The sequencer installed by Krone allows for a dynamic and<br />

100 percent automatic storage system: The components<br />

can be temporarily stored between all process steps using a<br />

push & pull conveyor system. Tractors push or pull the goods<br />

carriers in the direction of travel, and transverse movements<br />

are carried out via transfer bridges. This requires relatively<br />

little effort and enables the use of a light and energy-saving<br />

goods carrier. The sequencer holds around 200 chassis.<br />

The task of this dynamic storage is to decouple the coating<br />

system from the assembly. As a sequence controller, it also<br />

takes on the task of creating an optimum sequence with the<br />

aid of process automation prior to powder coating before<br />

the chassis enter the corresponding sequence for assembly<br />

and are passed on to the next finishing stage.<br />

7<br />

POWDER CHAMBERS<br />

Powder is applied to the chassis in this station: The system<br />

sprays the smallest particles in powder form as a cloud onto<br />

the statically charged workpiece. The vehicle is completely<br />

measured via a 3D scanning grid as it enters the powder<br />

chamber, and the 47 automatic spray heads arrange themselves<br />

at the optimum coating distance around the chassis<br />

in order to apply a uniform powder layer. After this step, the<br />

chassis is moved to the second level of the Coating Centre.<br />

8<br />

POWDER FURNACES<br />

The powder coating must also be treated in the furnace. The<br />

powder furnaces ensure that the particles slightly liquefy<br />

and then harden – in this way, they bond optimally to the<br />

CDP coating and firmly adhere to create a tough, impact-resistant<br />

surface.<br />

BUFFER ZONES AND<br />

TRANSFER TO ASSEMBLY<br />

The complete coating is finished, and the chassis is ready<br />

for installation. Thanks to process automation, it remains in<br />

the sequencer until it is requested. The assembly sequence<br />

for the chassis is already determined upon entry into the<br />

raw chassis buffer. When the assembly is requested, the<br />

finished coated chassis is placed in the specified sequence<br />

and sent for assembly.<br />

AT A GLANCE<br />

16,500<br />

13 months<br />

construction period<br />

40 mil. euros<br />

invested<br />

200 chassis<br />

storage capacity<br />

4<br />

tons<br />

square metres<br />

of facility space<br />

maximum<br />

weight capacity<br />

6.8 minute<br />

throughput frequency<br />

40 percent<br />

energy conservation