November 2018

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Tapered Insulation<br />

“Often we come across<br />

buildings that are not<br />

always full of right<br />

angles, and for these<br />

instances the installer<br />

may need to cut a<br />

bespoke angle on site”<br />

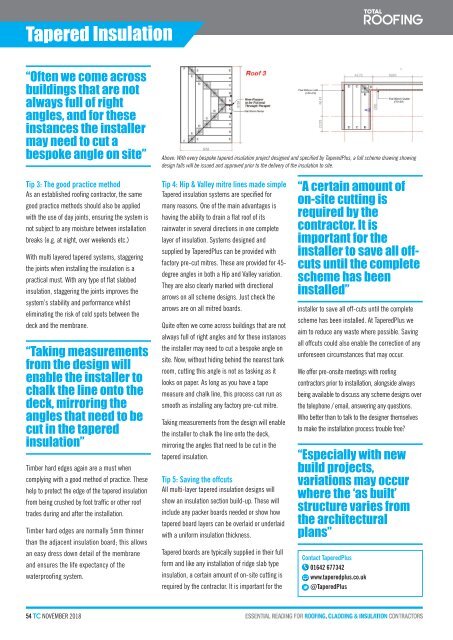

Above: With every bespoke tapered insulation project designed and specified by TaperedPlus, a full scheme drawing showing<br />

design falls will be issued and approved prior to the delivery of the insulation to site.<br />

Tip 3: The good practice method<br />

As an established roofing contractor, the same<br />

good practice methods should also be applied<br />

with the use of day joints, ensuring the system is<br />

not subject to any moisture between installation<br />

breaks (e.g. at night, over weekends etc.)<br />

With multi layered tapered systems, staggering<br />

the joints when installing the insulation is a<br />

practical must. With any type of flat slabbed<br />

insulation, staggering the joints improves the<br />

system’s stability and performance whilst<br />

eliminating the risk of cold spots between the<br />

deck and the membrane.<br />

“Taking measurements<br />

from the design will<br />

enable the installer to<br />

chalk the line onto the<br />

deck, mirroring the<br />

angles that need to be<br />

cut in the tapered<br />

insulation”<br />

Timber hard edges again are a must when<br />

complying with a good method of practice. These<br />

help to protect the edge of the tapered insulation<br />

from being crushed by foot traffic or other roof<br />

trades during and after the installation.<br />

Timber hard edges are normally 5mm thinner<br />

than the adjacent insulation board; this allows<br />

an easy dress down detail of the membrane<br />

and ensures the life expectancy of the<br />

waterproofing system.<br />

Tip 4: Hip & Valley mitre lines made simple<br />

Tapered insulation systems are specified for<br />

many reasons. One of the main advantages is<br />

having the ability to drain a flat roof of its<br />

rainwater in several directions in one complete<br />

layer of insulation. Systems designed and<br />

supplied by TaperedPlus can be provided with<br />

factory pre-cut mitres. These are provided for 45-<br />

degree angles in both a Hip and Valley variation.<br />

They are also clearly marked with directional<br />

arrows on all scheme designs. Just check the<br />

arrows are on all mitred boards.<br />

Quite often we come across buildings that are not<br />

always full of right angles and for these instances<br />

the installer may need to cut a bespoke angle on<br />

site. Now, without hiding behind the nearest tank<br />

room, cutting this angle is not as tasking as it<br />

looks on paper. As long as you have a tape<br />

measure and chalk line, this process can run as<br />

smooth as installing any factory pre-cut mitre.<br />

Taking measurements from the design will enable<br />

the installer to chalk the line onto the deck,<br />

mirroring the angles that need to be cut in the<br />

tapered insulation.<br />

Tip 5: Saving the offcuts<br />

All multi-layer tapered insulation designs will<br />

show an insulation section build-up. These will<br />

include any packer boards needed or show how<br />

tapered board layers can be overlaid or underlaid<br />

with a uniform insulation thickness.<br />

Tapered boards are typically supplied in their full<br />

form and like any installation of ridge slab type<br />

insulation, a certain amount of on-site cutting is<br />

required by the contractor. It is important for the<br />

“A certain amount of<br />

on-site cutting is<br />

required by the<br />

contractor. It is<br />

important for the<br />

installer to save all offcuts<br />

until the complete<br />

scheme has been<br />

installed”<br />

installer to save all off-cuts until the complete<br />

scheme has been installed. At TaperedPlus we<br />

aim to reduce any waste where possible. Saving<br />

all offcuts could also enable the correction of any<br />

unforeseen circumstances that may occur.<br />

We offer pre-onsite meetings with roofing<br />

contractors prior to installation, alongside always<br />

being available to discuss any scheme designs over<br />

the telephone / email, answering any questions.<br />

Who better than to talk to the designer themselves<br />

to make the installation process trouble free?<br />

“Especially with new<br />

build projects,<br />

variations may occur<br />

where the ‘as built’<br />

structure varies from<br />

the architectural<br />

plans”<br />

Contact TaperedPlus<br />

01642 677342<br />

www.taperedplus.co.uk<br />

@TaperedPlus<br />

54 TC NOVEMBER <strong>2018</strong>