Tropicana Magazine Nov-Dec 2018 #121: Festive Frivolities

Tropicana Magazine Nov_Dec issue#121 is all about the festive season's cheer and joy. Tis' also the time to travel and make time for your family, as everyday is an adventure if we choose to see it that way. Be jolly, to one & all!

Tropicana Magazine Nov_Dec issue#121 is all about the festive season's cheer and joy. Tis' also the time to travel and make time for your family, as everyday is an adventure if we choose to see it that way. Be jolly, to one & all!

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

CULTURE ADVERTORIAL | BOOKS<br />

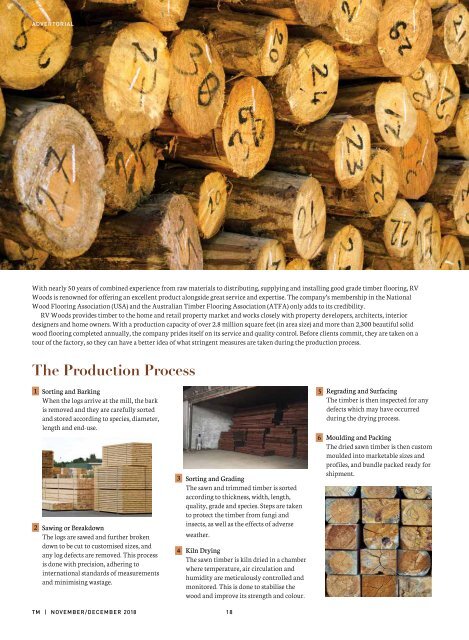

With nearly 50 years of combined experience from raw materials to distributing, supplying and installing good grade timber flooring, RV<br />

Woods is renowned for offering an excellent product alongside great service and expertise. The company’s membership in the National<br />

Wood Flooring Association (USA) and the Australian Timber Flooring Association (ATFA) only adds to its credibility.<br />

RV Woods provides timber to the home and retail property market and works closely with property developers, architects, interior<br />

designers and home owners. With a production capacity of over 2.8 million square feet (in area size) and more than 2,300 beautiful solid<br />

wood flooring completed annually, the company prides itself on its service and quality control. Before clients commit, they are taken on a<br />

tour of the factory, so they can have a better idea of what stringent measures are taken during the production process.<br />

The Production Process<br />

1 Sorting and Barking<br />

When the logs arrive at the mill, the bark<br />

is removed and they are carefully sorted<br />

and stored according to species, diameter,<br />

5 Regrading and Surfacing<br />

The timber is then inspected for any<br />

defects which may have occurred<br />

during the drying process.<br />

length and end-use.<br />

6 Moulding and Packing<br />

The dried sawn timber is then custom<br />

moulded into marketable sizes and<br />

profiles, and bundle packed ready for<br />

shipment.<br />

2<br />

Sawing or Breakdown<br />

The logs are sawed and further broken<br />

down to be cut to customised sizes, and<br />

any log defects are removed. This process<br />

is done with precision, adhering to<br />

international standards of measurements<br />

and minimising wastage.<br />

3 Sorting and Grading<br />

The sawn and trimmed timber is sorted<br />

according to thickness, width, length,<br />

quality, grade and species. Steps are taken<br />

to protect the timber from fungi and<br />

insects, as well as the effects of adverse<br />

weather.<br />

4<br />

Kiln Drying<br />

The sawn timber is kiln dried in a chamber<br />

where temperature, air circulation and<br />

humidity are meticulously controlled and<br />

monitored. This is done to stabilise the<br />

wood and improve its strength and colour.<br />

TM | NOVEMBER/DECEMBER <strong>2018</strong><br />

18