Boker Knifestyle | BUSA Edition 2020 / 2021

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

08<br />

BOKER PATINA DAMASCUS<br />

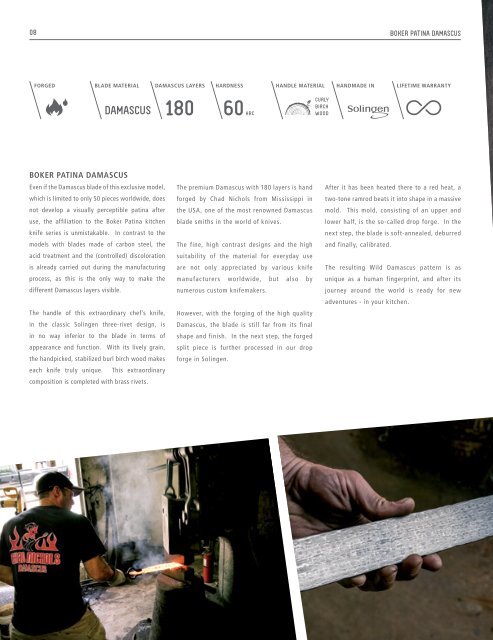

FORGED BLADE MATERIAL DAMASCUS LAYERS HARDNESS HANDLE MATERIAL HANDMADE IN LIFETIME WARRANTY<br />

DAMASCUS 180 60 HRC<br />

CURLY<br />

BIRCH<br />

WOOD<br />

BOKER PATINA DAMASCUS<br />

Even if the Damascus blade of this exclusive model,<br />

which is limited to only 50 pieces worldwide, does<br />

not develop a visually perceptible patina after<br />

use, the affiliation to the <strong>Boker</strong> Patina kitchen<br />

knife series is unmistakable. In contrast to the<br />

models with blades made of carbon steel, the<br />

acid treatment and the (controlled) discoloration<br />

is already carried out during the manufacturing<br />

process, as this is the only way to make the<br />

different Damascus layers visible.<br />

The handle of this extraordinary chef's knife,<br />

in the classic Solingen three-rivet design, is<br />

in no way inferior to the blade in terms of<br />

appearance and function. With its lively grain,<br />

the handpicked, stabilized burl birch wood makes<br />

each knife truly unique. This extraordinary<br />

composition is completed with brass rivets.<br />

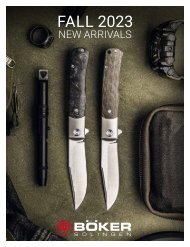

The premium Damascus with 180 layers is hand<br />

forged by Chad Nichols from Mississippi in<br />

the USA, one of the most renowned Damascus<br />

blade smiths in the world of knives.<br />

The fine, high contrast designs and the high<br />

suitability of the material for everyday use<br />

are not only appreciated by various knife<br />

manufacturers worldwide, but also by<br />

numerous custom knifemakers.<br />

However, with the forging of the high quality<br />

Damascus, the blade is still far from its final<br />

shape and finish. In the next step, the forged<br />

split piece is further processed in our drop<br />

forge in Solingen.<br />

After it has been heated there to a red heat, a<br />

two-tone ramrod beats it into shape in a massive<br />

mold. This mold, consisting of an upper and<br />

lower half, is the so-called drop forge. In the<br />

next step, the blade is soft-annealed, deburred<br />

and finally, calibrated.<br />

The resulting Wild Damascus pattern is as<br />

unique as a human fingerprint, and after its<br />

journey around the world is ready for new<br />

adventures - in your kitchen.