cpp – Process technology for the chemical industry 02.2020

The journal cpp - Process technology for the chemical industry reports about processes, plants, apparatus and components for the chemical and pharmaceutical industry. Further topics are IT technologies, industry 4.0, digital production, MSR and automation technology and process analysis technology. The content spectrum is rounded off by explosion protection, plant safety, occupational health and safety, maintenance, site management and energy management.

The journal cpp - Process technology for the chemical industry reports about processes, plants, apparatus and components for the chemical and pharmaceutical industry. Further topics are IT technologies, industry 4.0, digital production, MSR and automation technology and process analysis technology. The content spectrum is rounded off by explosion protection, plant safety, occupational health and safety, maintenance, site management and energy management.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>cpp</strong><br />

PLANTS, APPARATUS, COMPONENTS<br />

Diaphragm metering pumps in use in battery production<br />

Precise metering needed<br />

Ternary oxide systems containing lithium guarantee a high energy density, long<br />

service life and high number of charge cycles <strong>for</strong> lithium storage batteries. The<br />

quality of <strong>the</strong> precursors required <strong>for</strong> this depends on <strong>the</strong> precise and synchronous<br />

metering of various <strong>chemical</strong>s. The diaphragm metering pumps in <strong>the</strong> Gamma/ X and<br />

Sigma X ranges from Prominent play a key role in this.<br />

The demand <strong>for</strong> lithium batteries in <strong>the</strong><br />

communication, tools, automotive and<br />

energy sectors is high. Becoming increasingly<br />

lighter and with greater energy density,<br />

<strong>the</strong>y are replacing heavy lead or nickelcadmium<br />

batteries in <strong>the</strong>se applications.<br />

Lithium iron phosphate batteries cannot<br />

meet <strong>the</strong> requirements <strong>for</strong> electric mobility<br />

and stationary storage as <strong>the</strong> new generation<br />

of lithium batteries. Lithium-ion batteries<br />

with special cathode materials are replacing<br />

lithium iron phosphate batteries.<br />

The new power packs have a long service<br />

life with a high energy density and a large<br />

number of charge cycles with maximum<br />

safety. With carbon compounds containing<br />

lithium, <strong>the</strong>se properties can be put to use<br />

as anodes and, with a ternary oxide system<br />

containing lithium, as cathodes. Market researchers<br />

are anticipating above-average<br />

growth per year.<br />

NCA compounds<br />

Ternary precursors are being used <strong>for</strong> this.<br />

These are predominantly manufactured by<br />

means of reactions of nickel, cobalt and<br />

manganese solutions through hydroxide or<br />

carbonate precipitation. In this process, sodium<br />

hydroxide acts as a precipitant and<br />

ammonia as <strong>the</strong> complexing agent. For<br />

special applications, <strong>the</strong> manganese is replaced<br />

with aluminium solutions and receives<br />

NCA compounds. NCM or NCA precursors<br />

are obtained by various solutions<br />

being combined in precisely specified quantities,<br />

within a specific time frame, at specified<br />

temperatures, under stable conditions,<br />

and reacting accordingly. The reactions of<br />

<strong>the</strong> <strong>chemical</strong>s affect <strong>the</strong> critical properties of<br />

<strong>the</strong> precursors, such as <strong>the</strong> particle size and<br />

<strong>the</strong>ir specific surface. Strict proportional<br />

control of <strong>the</strong> reactants directly determines<br />

<strong>the</strong> final ternary material properties and<br />

<strong>the</strong>ir quality, as well as <strong>the</strong> purity of <strong>the</strong> sintered<br />

ternary lithium, nickel, cobalt and<br />

manganese (NCM) compounds. To obtain<br />

an exact quality in <strong>the</strong> precursors, and<br />

above all one that can be reproduced, smart<br />

high-end metering pumps are increasingly<br />

being used. These ensure <strong>the</strong> exact metering<br />

of <strong>the</strong> individual heavy metal solutions<br />

required <strong>for</strong> <strong>the</strong> reaction to achieve <strong>the</strong><br />

requisite precursor quality at all stages of<br />

production.<br />

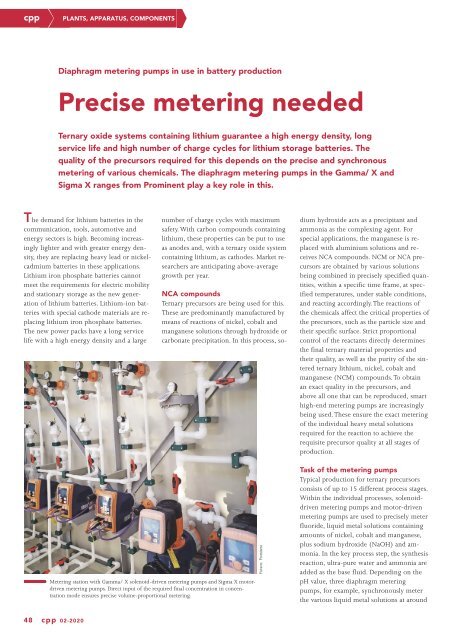

Metering station with Gamma/ X solenoid-driven metering pumps and Sigma X motordriven<br />

metering pumps. Direct input of <strong>the</strong> required final concentration in concentration<br />

mode ensures precise volume-proportional metering.<br />

Pictures: Prominent<br />

Task of <strong>the</strong> metering pumps<br />

Typical production <strong>for</strong> ternary precursors<br />

consists of up to 15 different process stages.<br />

Within <strong>the</strong> individual processes, solenoiddriven<br />

metering pumps and motor-driven<br />

metering pumps are used to precisely meter<br />

fluoride, liquid metal solutions containing<br />

amounts of nickel, cobalt and manganese,<br />

plus sodium hydroxide (NaOH) and ammonia.<br />

In <strong>the</strong> key process step, <strong>the</strong> syn<strong>the</strong>sis<br />

reaction, ultra-pure water and ammonia are<br />

added as <strong>the</strong> base fluid. Depending on <strong>the</strong><br />

pH value, three diaphragm metering<br />

pumps, <strong>for</strong> example, synchronously meter<br />

<strong>the</strong> various liquid metal solutions at around<br />

48 <strong>cpp</strong> 02-2020