ASPHALTopics | Summer 2014 | VOL 27 | NO3

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

a long<br />

ver<br />

way<br />

Ministry of Transportation, Cedarapids Asphalt Equipment<br />

dealer for Blackwood Hodge, and Miller Paving, he has a<br />

unique perspective.<br />

“I’ve seen quite a bit over the years. A lot has changed, but<br />

many of the basic concepts are the same,” he says. He adds<br />

that advances in the production process have been key to<br />

moving the industry forward, as have the pollution controls<br />

that are now in place. The introduction of RAP at higher<br />

percentage and the addition to the plants of hot mix<br />

surge/storage silos has improved the process.<br />

The first fuel used was heavy bunker oil; from there we<br />

moved to light fuel oil and natural gas, and now include<br />

propane and butane. Originally, the exhaust from the plants<br />

was released directly into the atmosphere. The introduction<br />

of cleaner burning fuels was followed with washer/<br />

scrubbers and fabric filter baghouses to satisfy stringent<br />

environmental controls which also included recirculating<br />

gases to the burner.<br />

Loughnan goes on to explain that back in the 1950s the<br />

pace was a lot slower and that a paving company employed<br />

more people than used today. More attention to detail was<br />

required with all the handwork.<br />

“You couldn’t do as much with that older equipment and<br />

lot of workers were necessary,” Loughnan says. Despite the<br />

equipment used 60 years ago, he’s quick to point out that<br />

the workmanship was at a high level. “Workers just had<br />

a different skill set back then, often using whatever tools<br />

they had.”<br />

Loughnan says paving equipment has evolved to keep up<br />

with the demands of the industry such as new materials,<br />

bigger projects and worker safety. Varying specifications<br />

also call for more versatility. He believes that one of the<br />

best advancements was the introduction of the vibratory<br />

steel roller which replaced three-wheeled static tired<br />

steel rollers. This allowed contractors to achieve<br />

desired compaction.<br />

“With the vibratory roller you could always achieve the<br />

desired compaction which made roads last longer and<br />

helped contractors enjoy performance bonuses by ››<br />

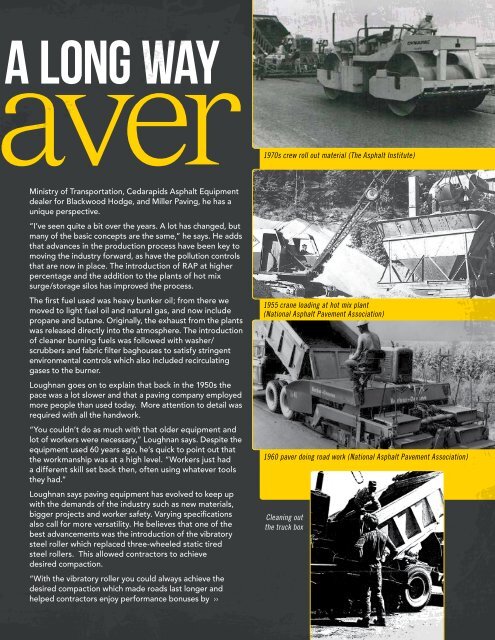

1970s crew roll out material (The Asphalt Institute)<br />

1955 crane loading at hot mix plant<br />

(National Asphalt Pavement Association)<br />

1960 paver doing road work (National Asphalt Pavement Association)<br />

Cleaning out<br />

the truck box