You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

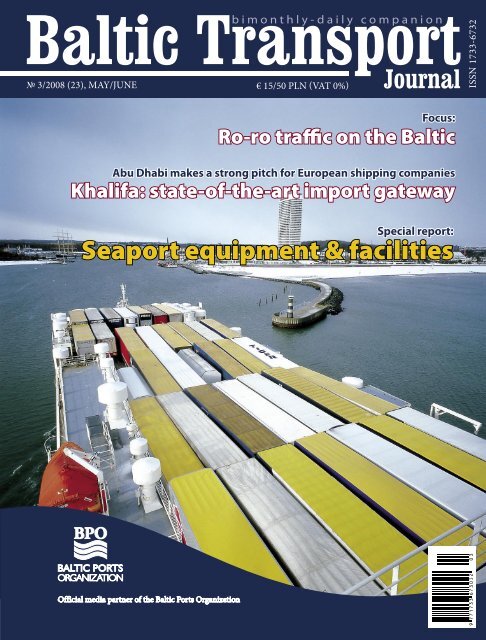

<strong>Baltic</strong> <strong>Transport</strong> 1733-6732<br />

<strong>Journal</strong> ISSN<br />

№ 3/<strong>2008</strong> (23), MAY/JUNE<br />

b i m o n t h l y - d a i l y c o m p a n i o n<br />

€ 15/50 PLN (VAT 0%)<br />

Focus:<br />

Ro-ro traffic on the <strong>Baltic</strong><br />

Abu Dhabi makes a strong pitch for European shipping companies<br />

Khalifa: state-of-the-art import gateway<br />

Special report:<br />

Seaport equipment & facilities

<strong>BTJ</strong> calendar of partnership events <strong>2008</strong>/2009 ........................................................... 8<br />

What’s new ............................................................................................................................... 10<br />

Just one question .................................................................................................................. 14<br />

Big country, promising market .......................................................................................... 16<br />

TransRussia <strong>2008</strong><br />

No traffic flow reorientation............................................................................................... 17<br />

A new policy for the European seaports<br />

The return of the city ............................................................................................................ 18<br />

Vuosaari project in its final stage<br />

Grimaldi calls for equal market conditions ................................................................... 20<br />

Successful in Europe, a Naples-based company feels not fairly treated at home<br />

Khalifa: state-of-the-art import gateway ....................................................................... 22<br />

Abu Dhabi makes a strong pitch for European shipping companies<br />

Report: Seaport equipment and facilities .................................................. 25<br />

<strong>Baltic</strong> Ports Organization newsletter .......................................................... 41<br />

Focus: Ro-ro traffic on the <strong>Baltic</strong>.................................................................. 45<br />

An extra 100,000 TEU for Gdynia and Kotka ................................................................. 49<br />

The <strong>Baltic</strong> Container Outlook <strong>2008</strong><br />

To those, who are not yet convinced .............................................................................. 50<br />

Towards a Destination Gdynia project<br />

Face to face with giants ........................................................................................................ 53<br />

Hamburg: a port as a tourist attraction<br />

The dry freight and tanker market ................................................................................... 56<br />

The low cost service is the model of the future .......................................................... 58<br />

An interview with John M. Kohlsaat, General Manager Commercial, easyJet<br />

State monopoly and its aftermath .................................................................................. 60<br />

Private carriers on fight for rail cargo in Poland<br />

Name yet unknown ............................................................................................................... 61<br />

Swedish and Danish post offices plan merger<br />

Anz_<strong>BTJ</strong>_<strong>2008</strong>_PG 07.05.<strong>2008</strong> 14:35 Uhr Seite 1<br />

<strong>Transport</strong> miscellany ............................................................................................................. 62<br />

S-XXL Container<br />

chassis<br />

In all sizes – for all sizes. Europe-wide over 4.000 container chassis. Rental,<br />

service and insurance, fleet management and sale & rent back, trading<br />

and finance.<br />

+ 49 40 - 37 689 732 – www.paulguenther.com<br />

Contents<br />

3/<strong>2008</strong> | <strong>Baltic</strong> <strong>Transport</strong> <strong>Journal</strong> | 3

Freight that bears fruit!<br />

To us, knowledge and cooperation are the route to financially<br />

and environmentally sustainable transportation. Together we<br />

harvest the fruits of our collective labours. We are right where<br />

we are needed – close to the market, close to you. Choose the<br />

Ports of Stockholm to improve the flow of your transportation.<br />

Ports of Stockholm Container Terminal – For great flow!

www.stoports.com<br />

www.hurra.se

Editorial<br />

<strong>Baltic</strong> <strong>Transport</strong><br />

<strong>Journal</strong><br />

Editor-in-Chief<br />

DARIUSZ SZRETER<br />

dariusz.szreter@baltictransportjournal.com<br />

Contributing Writers<br />

and Update Correspondents<br />

ALISON NISSEN, MAREK BŁUŚ, MICHAŁ GOMERSKI, MA-<br />

CIEJ KONOPIŃSKI, KUBA ŁOGINOW, MIKE ELSOM, OLGA<br />

ANISZCZUK, BARBARA ROGALSKA,<br />

ALEKSANDRA WIŚNIEWSKA, ERNEST CZERMAŃSKI, MANIK<br />

METHA, PER OLAF BRETT,<br />

PAWEŁ RYDZYŃSKI, NICOLA CAPUZZO,<br />

ARNOUD SERRY, PIOTR B. STAREŃCZAK<br />

English Language Editors<br />

ALISON NISSEN, KRYSTIAN BENNICH<br />

KRZYSZTOF WIERZBA<br />

Design and DTP<br />

MEDON<br />

Art Director<br />

DANUTA SAWICKA-ROMANOWSKA<br />

Graphic Designer<br />

MONIKA RÓŻYCKA<br />

Publisher<br />

BALTIC PRESS SP. Z O.O.<br />

Chairman<br />

DOROTA SOBIENIECKA<br />

dorota@baltictransportjournal.com<br />

Address: 8 Pułaskiego Street<br />

81-368 Gdynia, Poland<br />

office@baltictransportjournal.com<br />

tel. +48 58 627 23 94, tel. +48 58 627 23 95<br />

fax +48 58 621 69 66<br />

Internet: www.baltictransportjournal.com<br />

Marketing & Sales<br />

(advertising, tradefairs, conferences)<br />

PIOTR TRUSIEWICZ<br />

piotr@baltictransportjournal.com<br />

OLGA WOJDYGA<br />

olga@baltictransportjournal.com<br />

Subscriptions<br />

KAROLINA KARPIŃSKA<br />

karolina@baltictransportjournal.com<br />

Print<br />

MEDON<br />

Address: Medon sp. j.<br />

ul. Kartuska 245, 80-125 Gdańsk, Poland<br />

e-mail: medon@medon.gda.pl<br />

Internet: www.medon.gda.pl<br />

Circulation: 2,500<br />

Cover photo: Finnlines<br />

Subscriptions can be ordered<br />

in Kolporter offices in Poland.<br />

For more information call 0801-205-555 or visit<br />

www.kolporter-spolka-akcyjna.com.pl/prenumerata.asp<br />

6 | <strong>Baltic</strong> <strong>Transport</strong> <strong>Journal</strong> | 3/<strong>2008</strong><br />

Dear Readers,<br />

Are sea-ports over-invested? Per Olaf Brett put such a thesis forward in the last issue of<br />

<strong>BTJ</strong> provoking varied and emotional reactions among our readers. Naturally, issues<br />

like these will be viewed differently depending on who voices an opinion. One thing<br />

is beyond a doubt, however, irrespective of whether or not we consider part of the investments<br />

as being too big – over the last years ports have lived through a period of<br />

unprecedented prosperity. This translates into a growing need for seaport equipment and facilities. In<br />

our special report we have presented some of the offers from a sumptuous catalogue of manufacturers.<br />

Even though the <strong>Baltic</strong> market constitutes a fragment of all their clients, many interesting investments<br />

are being launched here.<br />

One of them is the new port of Vuosaari in Helsinki, which has been heralded for a long time now.<br />

Interestingly, this giant investment, which is to be ready in the fall of this year, was initiated not so<br />

much to increase the volume but rather on account of the city and its inhabitants. The object was not<br />

to make the port’s operations tedious for the surrounding inhabitants. This illustrates a very peculiar<br />

way of thinking about transport and its role in everyday life. We, the dwellers of the <strong>Baltic</strong> Sea Region,<br />

should be proud of such an attitude.<br />

When talking about new investments in this issue of the <strong>BTJ</strong>, we offer you a trip to Abu Dhabi<br />

– a region in the Middle East – where a very modern port and a business centre is underway. Investors,<br />

while looking around for prospective trade partners, have come all the way to Northern Europe to encourage<br />

local logistics companies to use their port as a hub for the Middle East. This is why, even though the<br />

majority of freight forwarders are first of all thinking of trading with the Far East, it is well worth taking a<br />

look at this offer. We also deemed it interesting to take a glance at the Mediterranean Sea where Grimaldi<br />

Group, one of the world’s largest ro-ro fleet owners, is having a dispute with its own government over<br />

unequal treatment and intervention on behalf of a public player on the sea transport market. Grimaldi<br />

Group is also the majority share-holder of Finnlines on the <strong>Baltic</strong> Sea.<br />

The influence of politics on the sea transport sector is the subject of an article by Patrick Verhoeven,<br />

Secretary General of ESPO. It will be possible to discuss this issue in detail during the planned June expos<br />

– TOC Europe and Posidonia – as well as during the conferences which accompany them.<br />

As we are already on the issue of expos, bearing in mind the upcoming ROROex, we have prepared a<br />

focus on ro-ro traffic on the <strong>Baltic</strong> Sea. Anyone interested is welcome to join us in Gothenburg. Meet us at<br />

ROROex, 20-22 May, stand A11.<br />

Dariusz Szreter<br />

editor-in-chief<br />

Company index<br />

ABB 38; Abu Dhabi International Airport 23; Abu Dhabi Ports Company 22-23; ACE Link 45; Actia Consulting 49; Airbus 12; Alitalia 21;<br />

Alrosa 32; Archirodon Construction 23; Atlantic Container Line 20-21; Atomstroiexport 32; Attica 46; AXS-Alphaliner 10; <strong>Baltic</strong> Scandinavia<br />

Line 46; Baltkran 32; BCT 15; Beluga Shipping 44; Boeing 12; Bornholmstrafikken 46; Boskalis Westminster Middle East 23; Brussels<br />

Airlines 12; Cargotec 31; Castellammare di Stabia 20; Chocolat Frey 62; CMP 15; Cobelfret 38; Color Line 46; Corus Rail 13; CTA 53; CVC<br />

61; CVS Ferrari 29-30; Czech Railways 16; DCT Gdańsk 10, 41; Delta Shipping Lines 44; Destination Gotland 45-46; Deutsche Bahn 13, 35;<br />

Dexter 12; DFDS 11, 35, 46; easyJet 58; Eckero Line 46; Estonian Railways 16; Eurogate 10; Euroterminal Sławków 58; Fantuzzi Reggiane<br />

29, 33, 34; Fincantieri 20; Finnlines 6, 20-21, 45-46; Finnsteve 19; Gazprom 32; GTK 44; GE Energy 55; Gottwald 26-31, 44; Green Carrier<br />

16; Grimaldi 6, 20-21; Helsinki-Vantaa Airport 18; HH Ferries 46; HHLA 53; Hyundai Engineering and Construction 23; ICTSI 15; IMPSA<br />

29; Italgru 33; Kalmar 29, 31; Khalifa Port and Industrial Zone 22-23; Konecranes 29-31; Laem Chabang Container Terminal 10; Latvian<br />

Railways 16; Liebherr 27-30, 33; LindaLine 45; Lithuanian Railways 16; LOT 12, 58; Lufthansa 12, 58; Lukoil 32; Maersk 10, 11; Malév 58;<br />

Management Group Pomerania 42; Midland Airways 12; Minoan Lines 20-21; Mols Linien 45-46; MSC 49, 62; Multi-Link Terminals 19;<br />

NCC 10, 32; Noell 32, 34; Nordic Jet 46; Novatug 39; Orvelin 46; Paceco 27; P&O Nedlloyd 10; PCC Rail 13; PGE 54; Polferries 46; PKP<br />

Cargo 13, 16, 60; PKP LHS 16, 60; PKP PLK 13, 60; Port of Aabenraa 33; Port of Aarhus 44, 49; Port of Amsterdam 39; Port of Antwerp 15,<br />

21, 39, 47; Port of Bilbao 47; Port of Dubai 22, 39; Port of Gdańsk 42, 44, 54-55, 60; Port of Gdynia 42, 46, 47, 49, 50, 60; Port of Gioia Tauro<br />

35; Port of Göteborg 38-39, 44, 46, 49; Port of Hamburg 10, 14, 39, 44, 53; Port of Hanko 47; Port of Helsingborg 46; Port of Helsingør<br />

46; Port of Helsinki 18-19, 35, 44, 45-46, 49; Port of Hong Kong 49; Port of Houston 39; Port of Kaliningrad 34; Port of Karlskrona 46; Port<br />

of Kemi 46; Port of Kotka 16, 35, 46, 49; Port of Los Angeles 39; Port of Lübeck 39, 41, 46, 47; Port of Malmö 45-46; Port of Melbourne<br />

39; Port of Mina Zayed 23; Port of Monfalcone 20; Port of Muuga 16, 35; Port of New Jersey 39; Port of New York 39; Port of Ningbo 16;<br />

Port of Oulu 46; Port of Rostock 44, 46; Port of Rotterdam 10, 15, 44, 49; Port of Santos 35, 39; Port of Shanghai 39, 49; Port of Sillamäe<br />

46; Port of Singapore 39, 49; Port of Södertälje 44; Port of St. Petersburg 10, 33, 44, 49; Port of Stockholm 41, 46; Port of Szczecin 44,<br />

60; Port of Świnoujście 46; Port of Tallin 45-46; Port of Tilbury 47; Port of Tokyo 39; Port of Trelleborg 46; Port of Ust-Kut 32; Port of Ust-<br />

Luga 33; Port of Uusikaupunki 46; Port of Zeebrugge 47; Ports of Stockholm 41; Post Danmark 61; Posten 61; PSA International 10; Rail<br />

Cargo Austria 16; Rail4Chem 13; RG Line 46; Riga Airport 12, 58; Rosmorport 45-46; Russian Railways (RZD) 13, 16, 32; Ryanair 12, 58;<br />

SAAB 62; SAS 11; Scandlines 46; Slovak Railways 16; Spliethoff 47; SSC Ferries 46; Stal 32; Stena Line 14, 39, 46; Steveco 19; Stora Enso<br />

35, 38; Subsea Industries 44; Superseacat 46; Surgutneftegas 32; Swan Container Line 10; Tallink 10, 46; TAP 12; Team Lines 49; TGV<br />

13; Tirrenia 21; Trade Trans 16; Transatlantic 46; Transfennica 46-47; TT Line 46; Uljanik yards 20; Unifeeder 49; Unity Line 20, 46; Veolia<br />

Cargo 13; Viking Line 46; Virgin 12; Visy 35; Vodafone 11; VR Cargo 16; Vuosaari Harbour 6, 18-19, 35; Wagenborg Shipping 38; Wallenius<br />

Wilhelmsen 44; ZPMC 29; Züblin/Aarsleff 44;

<strong>BTJ</strong> calendar of partnership events <strong>2008</strong>/2009<br />

<strong>BTJ</strong> 3/<strong>2008</strong> (May-June edition)<br />

Issue distributed at:<br />

Roroex <strong>2008</strong> Expo<br />

20-22 May <strong>2008</strong>, SE/Göteborg<br />

www.roroex.com<br />

ICCMI <strong>2008</strong> Conference<br />

2-4 June <strong>2008</strong>, SE/Malmö<br />

www.iccmi.info<br />

Posidonia <strong>2008</strong> Expo<br />

3-6 June <strong>2008</strong>, GR/Athens<br />

www.posidonia-events.com<br />

East-West Intermodal<br />

Conference<br />

4-5 June <strong>2008</strong>, PL/Warsaw<br />

www.informedia-polska.pl<br />

E-logistics Networking<br />

Conference<br />

5-6 June <strong>2008</strong>, PL/Tomaszowice<br />

www.transporeon.com<br />

TOC Europe Expo<br />

17-19 June <strong>2008</strong>, NL/Amsterdam<br />

www.tocevents-europe.com<br />

<strong>BTJ</strong> 4/<strong>2008</strong> (July-Aug. edition)<br />

Issue distributed at:<br />

BPO XI General Assembly<br />

September <strong>2008</strong>, DE/Lübeck<br />

www.bpoports.com<br />

Airports <strong>2008</strong> Conference<br />

September <strong>2008</strong>, PL/Warsaw<br />

www.actiaconferences.com<br />

<strong>BTJ</strong> 5/<strong>2008</strong> (Sept.-Oct. edition)<br />

Issue distributed at:<br />

Innotrans <strong>2008</strong> Expo<br />

23-26 September, DE/Berlin<br />

www.innotrans.com<br />

<strong>Baltic</strong> Ro-ro and Ferry<br />

Conference <strong>2008</strong><br />

October <strong>2008</strong>, tba<br />

www.actiaconferences.com<br />

CEE Rail <strong>2008</strong> Conference<br />

27-29 October <strong>2008</strong>, HU/Budapest<br />

www.terrapinn.com/<strong>2008</strong>/cee_rail<br />

<strong>BTJ</strong> 6/<strong>2008</strong> (Nov.-Dec. edition)<br />

Issue distributed at:<br />

Intermodal <strong>2008</strong> Expo<br />

18-20 November <strong>2008</strong><br />

DE/Hamburg<br />

www.intermodal-events.com<br />

<strong>Baltic</strong>Future <strong>2008</strong> Expo<br />

18-20 November <strong>2008</strong>, DE/Rostock<br />

www.expotec-international.com<br />

8 | <strong>Baltic</strong> <strong>Transport</strong> <strong>Journal</strong> | 3/<strong>2008</strong><br />

TRANSPOREON<br />

SOLUTIONS FOR E-LOGISTICS<br />

Special Report: Seaports equipment & facilities<br />

Focus: Ro-ro trafic on the <strong>Baltic</strong><br />

Bi-annual exhibition and conference held exclusively for the roll-on/roll-off shipping industry. A<br />

“must attend” meeting place for all the principal operators, suppliers and service providers using<br />

ro-ro and horizontal handling methods.<br />

“Impacts of Climate Change on the Maritime Industry” Conference will be a cornerstone of WMU the<br />

Silver Jubilee celebration, attracting experts from around the globe to discuss how climate change<br />

might affect various maritime and coastal activities, also evaluating measures to ensure the sustainability<br />

of maritime industries.<br />

With over 1,600 exhibitors every 2 years the international shipping community gathers at Posidonia. Besides<br />

showcasing new products, services and technological breakthroughs, the event provides great networking<br />

opportunities and discussions with senior, technical and operations management of shipping companies.<br />

“Intermodal <strong>Transport</strong> in the East-West Commerce” is the topic of a 2-day international conference in Warsaw,<br />

Poland. The agenda includes costs optimization, meeting deadlines, quality and effectiveness of the services<br />

in efficient logistic models, insurances and guarantee systems, Euro 2012 and the construction boom in Poland,<br />

the most perspective economical markets: Ukraine, China and Asian countries.<br />

The first conference for Central and Eastern European logistic managers devoted entirely to introducing sophisticated<br />

solutions for optimizing logistic processes. Guests include representatives of international companies<br />

(Whirlpool, Curver) and academic researchers. Organised for you by TRANSPOREON. Free entrance.<br />

TOC Europe <strong>2008</strong> edition will help you to find in-depth information about the port industry in the Netherlands,<br />

better understand its impact on European shipping and make good business in the area. The accompanying<br />

conference will also deal with the challenges European ports face for their growth and the future.<br />

Special Report: Maritime-Aviation ranking <strong>2008</strong><br />

Focus: Chinese boom & BSR economy dynamics<br />

Fifty major <strong>Baltic</strong> seaports’ annual meeting and a conference gathering executives from ports, portrelated<br />

industries, international organisations, members of the European Parliament, consulting<br />

companies, academia and professional media. Organised by Actia Forum Ltd.<br />

The four-year old conference provides a well-known meeting place for the aviation business in Poland,<br />

the CEE fastest growing market. Delegates from various European countries will deal with the challenges<br />

of increasing passenger/cargo traffic in Polish airports.<br />

Special Report: <strong>Baltic</strong> ship suppliers’ guide<br />

Focus: Railway innovations<br />

Focusing on railway technology the expo has become the European platform for transport engineering<br />

industry buyers and sellers both in passenger and cargo transport. Over 1,600 exhibitors and about<br />

66,000 international visitors make for countless business opportunities for everybody.<br />

The event concentrating on ro-ro, ro-pax and con-ro traffic on the <strong>Baltic</strong> Sea, giving a thorough insight<br />

into shipping/port/hinterland matters, actual trends in vessels technology and ro-ro shippings role in the<br />

region’s logistics network.<br />

Central & Eastern Europe’s leading rail conference, designed to provide valuable insight into what drives this<br />

booming industry and the challenges being faced. Last year’s edition featured 45 high level speakers. Expect<br />

two days of focused discussion dedicated to freight, infrastructure and passenger services.<br />

Special Report: Rail-Road ranking for <strong>2008</strong><br />

Focus: Key logistics players<br />

The world’s leading intermodal event comprised of a comprehensive exhibition and a conference<br />

held uninterruptedly for 32 years, with its last edition showcasing products/services of over 100<br />

companies and speeches from 30 acclaimed speakers. A must attend for professionals involved in<br />

the container business.<br />

International expo for innovations, technology, trade and services from the private and public<br />

sector of the maritime supply industry, addressing professionals from the <strong>Baltic</strong> Sea area, UK and<br />

the western North Sea region. The event will be accompanied by seminars, workshops, networking<br />

service and a Come-Together-Party.

<strong>BTJ</strong> 2009 partnerships<br />

EuroRail 2009 Conference<br />

23-25 February 2009, DE/Berlin<br />

www.terrapinn.com/2009/eurorail<br />

SITL Real Time 2009 Expo<br />

24-26 March 2009, FR/Paris<br />

www.sitl.eu<br />

<strong>Transport</strong> Logistic 2009 Expo<br />

12-15 May 2009, DE/Munich<br />

www.transportlogistic.com<br />

TRAKO 2009 Expo<br />

14-16 October 2009, PL/ Gdańsk<br />

www.mtgsa.pl<br />

Dates and places of the events are subject to be changed by the organizing parties.<br />

<strong>BTJ</strong> calendar of partnership events <strong>2008</strong>/2009<br />

Now in its 12th year, EuroRail 2009 marries its exceptional pedigree with new topics of marketing,<br />

distribution and revenue management. EuroRail provides a forum where you can debate<br />

the big commercial questions with your peers, whilst making those all-important contacts.<br />

Get ahead. Take the lead in logistics performance. SITL Real Time brings together in one place<br />

the total transport and logistics chain. 25 800 professional attendees, 500 exhibitors, a conference<br />

program with more than 30 sessions. Check the official website for more information.<br />

The world’s largest exhibition (with 90,000m², 1,582 exhibitors and 47,636 visitors from 118<br />

countries) for the transport, logistics and telematics sector with innovative solutions and products<br />

for the entire value-added chain. An absolute must for anyone who wants to move things<br />

in this sector.<br />

The most prestigious rail industry meeting in Poland and one of the largest in Central and<br />

Eastern Europe. It is the perfect opportunity to promote agglomeration rail transport, freight<br />

forwarding and logistics, to present the latest technologies and hold meetings within the industry.<br />

TRAKO is organised in partnership with Polish State Railways (PKP S.A.). The event is accompanied<br />

by an extensive programme which includes numerous seminars, conferences and<br />

company presentations.<br />

or just enter www.baltictransportjournal.com and click: SUBSCRIPTION<br />

3/<strong>2008</strong> | <strong>Baltic</strong> <strong>Transport</strong> <strong>Journal</strong> | 9

What’s new?<br />

Maritime<br />

Danish container shipping company<br />

Maersk Line is gradually recapturing its<br />

market share, shown in a new report by<br />

French AXS-Alphaliner. The company<br />

boosted its global market share in terms of<br />

TEU capacity from 16.0% at the beginning<br />

of <strong>2008</strong> to 16.4% in April <strong>2008</strong>. Maersk Line<br />

had an 18.2% market share in 2005 which<br />

fell to 16.8% in January 2007, reflecting the<br />

difficulties the company experienced after<br />

acquiring P&O Nedlloyd.<br />

The new generation high speed vessel M/S<br />

Superstar was delivered to the Estonian AS<br />

Tallink Group’s subsidiary Tallink Superfast<br />

Ltd. The new 1A ice class vessel has a speed<br />

of 27 knots, which enables it to sail between<br />

Helsinki and Tallinn in less than two hours.<br />

M/S Superstar is 175.1 m long and 27.6 m<br />

wide and is a bit bigger than her sister vessel<br />

M/S Star. It accommodates up to 2,080 passengers<br />

and 1,930 lane meters of vehicles.<br />

The ship has 186 cabins and 736 berths.<br />

The Germany-based container terminal and<br />

logistics group Eurogate will invest EUR 1.1<br />

billion to expand its facilities in Europe over<br />

the next four years. The investment will include<br />

50 new super-post-Panamax gantry<br />

cranes between <strong>2008</strong>-2012. In 2007, the EU-<br />

ROGATE Group handled 13.9m TEU Europewide,<br />

10.6% more than in the previous year.<br />

Since 2003 Swan Container Line GmbH<br />

& Co. KG has offered a regular service between<br />

Hamburg and St. Petersburg (First<br />

Container Terminal). The service from<br />

Hamburg and Rotterdam was operated<br />

by M/V <strong>Baltic</strong> Swan (720 TEU) and M/V<br />

Berit (612 TEU) on a weekly basis. A third<br />

vessel, the M/V Mistral (612 TEU), was put<br />

into service from April <strong>2008</strong>. With this the<br />

frequency increases to 2 times per week.<br />

The rotation of the ship is: Rotterdam-St.<br />

Petersburg-Hamburg-Rotterdam. The<br />

transit time between Rotterdam and St.<br />

Petersburg is 3-4 days. The ship leaves<br />

Rotterdam every Monday and Saturday.<br />

In January-March <strong>2008</strong>, the total throughput<br />

of Russian National Container Company<br />

(NCC) amounted to 423,103 TEU<br />

which is an increase of 21.1% compared<br />

to January-March 2007. The throughput of<br />

the largest NCC’s container terminal – FCT,<br />

at the sea port of Saint-Petersburg came to<br />

256,399 TEU which exceeds the results of<br />

January-March 2007 by 17%.<br />

10 | <strong>Baltic</strong> <strong>Transport</strong> <strong>Journal</strong> | 3/<strong>2008</strong><br />

IMO’s new fuel regulations can increase<br />

shipping rates<br />

The Marine Environment Protection<br />

Committee (MEPC) of the International<br />

Maritime Organization (IMO) approved<br />

major changes to the MARPOL Annex VI<br />

regulations to reduce harmful emissions from<br />

ships. Sulphur oxide (SOx) emissions will be<br />

reduced by lowering the global cap on sulphur<br />

in fuel from 4.50% to 3.50% on 1 January<br />

2012 and then progressively to 0.50% on<br />

1 January 2020. In Sulphur Emission Control<br />

Areas (SECAs), limits would be reduced from<br />

1.50% to 1.00% on 1 March 2010 and then to<br />

0.10% on 1 January 2015. The <strong>Baltic</strong> Sea and<br />

North Sea are the only marine areas defined<br />

as SECAs. “This is a real ocean-sized change<br />

for the IMO. After a decade and a half of discussion<br />

and pressure from environmentalists<br />

around the world, the IMO has recognized<br />

the need for clean shipping fuels,” said Eelco<br />

Leemans of the North Sea Foundation, representing<br />

Friends of the Earth International.<br />

The new regulations come at a time when<br />

environmental organisations published the<br />

results of research indicating that more than<br />

80,000 premature deaths annually worldwide<br />

New CEO in DCT Gdańsk<br />

Boris Wenzel was appointed CEO of the<br />

container terminal operator DCT Gdańsk<br />

SA. He succeeds Colin Chanter, who continues<br />

as Chairman of the Management Board.<br />

Wenzel brings to DCT Gdańsk a wealth of port<br />

industry experience with a strong financial<br />

and business development bias. Educated in<br />

France, Mr Wenzel spent his very early career in<br />

Barcelona, New York and London before joining<br />

a leading Thai investment bank in 1995.<br />

His introduction to the port industry came in<br />

1999 when he joined as General Manager of<br />

the Eastern Sea Laem Chabang Container Terminal,<br />

one of several terminal operators in the<br />

due to shipping pollution could be reduced<br />

with caps on sulphur. It should be noted that<br />

new sulphur limits present a considerable<br />

challenge for the oil and shipping industry<br />

which will probably result in significant additional<br />

fuel costs. Bunker fuel already costs<br />

around USD 500/ton and low-sulphur marine<br />

diesel fuel costs $790-860/ton. A 10,000 deadweight<br />

tonnage ship uses about 20 tons/day<br />

of bunker fuel. “There is a potential danger<br />

that the additional costs for short sea shipping<br />

will result in a shift from the sea to the<br />

less environmentally credible land-based<br />

transport. This environmentally counterproductive<br />

consequence will need to be<br />

addressed in the context of the application<br />

of the IMO Agreement in the EU,” said the<br />

European Community Shipowners’ Associations<br />

in a statement.<br />

Annex VI Regulations for the Prevention<br />

of Air Pollution from Ships entered into<br />

force in May 2005 and has been ratified by<br />

49 countries, representing approximately<br />

74.77% of the gross tonnage of the world’s<br />

merchant shipping fleet.<br />

new Thai port of Laem Chabang as General<br />

Manager. Successive promotions saw him appointed<br />

President and CEO in 2002. From Laem<br />

Chabang he moved to PSA International in<br />

2003 where he played key roles in the international<br />

expansion programme of PSA, including<br />

projects in Turkey, India, Belgium and Portugal.<br />

At the same time Danuta Biłat, formerly commercial<br />

manager, takes on the wider role as sales<br />

and marketing manager. Board Director Derek<br />

Peters will remain as senior marketing adviser to<br />

the new CEO and the responsibility for all day to<br />

day management of the company remains with<br />

General Manager Fred Kamperman.

New vice president of DFDS Seaways<br />

The Danish shipping company DFDS, appointed<br />

Carsten Jensen as new Manager of the<br />

Business Unit Passenger and also as new head<br />

of DFDS Seaways. Carsten Jensen, who comes<br />

from a post as deputy director at DFDS Seaways,<br />

simultaneously takes up a position with<br />

DFDS’ Executive Management. Following<br />

Carsten Jensen’s statement, he wants to focus<br />

on making DFDS Seaways a stronger business<br />

and even better workplace in close co-operation<br />

with the Executive Management and the<br />

employees. Carsten Jensen is 44 years old and<br />

has an MSc in Economics and Business Administration.<br />

He gained solid international<br />

experience from SAS, which he moved to in<br />

1995 and where he had management respon- rienced leader, who knows and loves the shipsibilities<br />

with customer relations, marketing, ping company, its employees and customers. I<br />

price policy, sales and operations, including in have no doubts that he is the right person to<br />

Stockholm, before becoming German director ensure DFDS Seaways’ continued success and<br />

for SAS in Frankfurt. “I am very happy to be dynamism,” said Niels Smedegaard, DFDS’<br />

able to hand over the helm to Carsten Jensen, CEO. DFDS Seaways is the passenger-carrying<br />

who brings some excellent ballast to the job. division of DFDS. The company operates the<br />

Partly through his place in the company’s man- passenger routes Copenhagen-Oslo, Esbjergagement<br />

since 2005, partly due to his previous Harwich, IJmuiden-Newcastle and Bergen/<br />

valuable experience from international man- Haugesund/Stavanger-Newcastle. DFDS Seaagement<br />

AD 320trucks positions. 205x135 Carsten (PL) Jensen 07-05-14 will provide 11.33 ways Sida transports 1 around 1.5 million passengers<br />

DFDS Seaways as a sharp analyst and an expe-<br />

per year on six ferry cruise ships.<br />

Gdynia–Karlskrona<br />

EXTRA<br />

CAPACITY<br />

Now you can book more space. And deliver more often.<br />

We’ve expanded our fleet on the popular Gdynia–Karlskrona route. The “Finnarrow” is a new<br />

reinforcement that gives an extra daily departure with capacity for 120 trucks – increasing the<br />

overall route capacity by 60%.<br />

And with another departure time, you’ll be able to fit more deliveries into your schedule.<br />

Maritime<br />

What’s new?<br />

The government of the Republic of<br />

Latvia gave the go-ahead for a EUR<br />

500m natural gas terminal to be built between<br />

2010 and 2013. Anicetas Ignotas,<br />

the Economy Ministry’s undersecretary,<br />

told a parliamentary committee that the<br />

LNG terminal with an annual capacity<br />

of 2 billion cubic meters would cover<br />

an area of 3-9 hectares. With more than<br />

8,000 kilometres of gas-mains and distribution<br />

networks, nearly 1,700 kilometres<br />

of gas-mains and about 6,600 kilometres<br />

of distribution networks, Lithuania has<br />

an extensive gas network.<br />

At the Annual General Meeting of A.P.<br />

Møller Maersk Sir John Bond (chairman<br />

of Vodafone Group Plc.), Mr. Lars Pallesen<br />

(rector at the Technical University of Denmark)<br />

and Mr. John Axel Poulsen (captain<br />

in A.P. Møller Maersk) were elected as new<br />

members of the Board of Directors of A.P.<br />

Møller Maersk. According to the pressservice<br />

of the company, at the same time,<br />

Mr. Svend-Aage Nielsen and Mr. Henrik<br />

Lorensen resigned as nominee directors.<br />

For more information give us a call or drop us a line at freight.info@stenaline.com www.stenalinefreight.com Tel +48 (0)58 660 92 97 Fax: +48 (0)58 621 33 08<br />

3/<strong>2008</strong> | <strong>Baltic</strong> <strong>Transport</strong> <strong>Journal</strong> | 11

What’s new?<br />

Aviation<br />

During the first three months of <strong>2008</strong>,<br />

Lufthansa carried a record number of passengers.<br />

Its passenger numbers rose by 5.5%<br />

to 13m in the first quarter. Revenue seat-kilometres<br />

climbed 5.9%, lifting the passenger<br />

load factor by 0.2% to 77.2%. Passenger numbers<br />

were up in all traffic regions. Lufthansa<br />

Cargo also improved its performance in terms<br />

of cargo volume and capacity utilisation in<br />

the first quarter. The Lufthansa subsidiary<br />

transported 429,000 tons of freight and mail,<br />

0.4% more than in the same period last year.<br />

The cargo load factor rose to 69.5%.<br />

The Boeing Co. announced another delay<br />

involving its 787 jetliner, pushing back<br />

its expected debut in commercial service<br />

to the third quarter of 2009. It’s the fourth<br />

time Boeing has had to revise the schedule<br />

for the top-selling plane which has been<br />

plagued by supply-chain problems. The first<br />

global network airline in Europe operating<br />

Boeing 787 will be LOT Polish Airlines.<br />

The European concern Airbus announced<br />

a rise in prices across its range of aircraft,<br />

blaming rising metals prices and the weakness<br />

of the US dollar. The list prices of singleaisle<br />

planes rose EUR 2m while wide-body,<br />

long range, and A380 aircraft increased by<br />

EUR 2.5m. The average price for an A380 is<br />

EUR 210m while an A320 is EUR 50m.<br />

The first Russian air taxi Dexter obtained<br />

an official permit for international transportation<br />

and from June <strong>2008</strong> will start to carry<br />

out flights to Finland, the <strong>Baltic</strong> countries,<br />

and to a number of the CIS states. Dexter is<br />

planning to use Swiss Pilatus aircraft which<br />

have eight seats and can cover a distance<br />

of up to 2,000 kilometres at a speed of<br />

450km/h. By the end of the year the company’s<br />

aircraft park will expectedly have 13<br />

Pilatus aircraft and 3 Russian M-101 T aircraft<br />

that have 4-5 seats. Officially the company<br />

is based in Bykovo airport in Moscow.<br />

A EUR 200m investment is planned for the<br />

development of Riga International Airport.<br />

In the first stage the plan is to prepare the airport<br />

to handle 12m passengers per year. The<br />

second stage foresees demolishing the existing<br />

buildings in the southerly direction to construct<br />

new space for the airport. This will allow<br />

an even more increased passenger flow – up<br />

to 20m per year. The first stage is to be completed<br />

by year 2011. The number of passengers<br />

handled by Riga Airport last year was 3.6m.<br />

12 | <strong>Baltic</strong> <strong>Transport</strong> <strong>Journal</strong> | 3/<strong>2008</strong><br />

Growing fuel costs hit airlines<br />

Europe’s second-largest airline, Lufthansa, maintained its financial outlook for <strong>2008</strong> but warned<br />

that operating costs in the first quarter of <strong>2008</strong> rose sharply, driven mainly by soaring fuel prices.<br />

“The challenges posed by increased prices, particularly the price of fuel, as well as uncertain economic<br />

development, will increase for Lufthansa. For this reason, all of the group companies are<br />

keeping their focus on cost management,” the Germany-based airline said in a statement.<br />

The company spent EUR 1.07 billion on fuel in the first quarter of <strong>2008</strong>, up 42% from the previous<br />

year. However, positive EUR/USD currency effects and fuel hedging helped to offset some<br />

of the increases. These factors lowered the additional fuel costs by EUR 97m and fuel hedging by<br />

EUR 131m in the first three months of <strong>2008</strong>. This year, the company will probably spend EUR<br />

5.26 billion on fuel, up 36% from last year – more than the March forecast of EUR 4.9 billion. To<br />

sustain earnings, Lufthansa decided to impose fuel surcharges on its ticket prices. The company<br />

levied a EUR 77 fee on long-haul flights and EUR 17 on European services.<br />

Another airline tries to stand up against high fuel costs. Belgium’s Brussels Airlines is looking<br />

at nearly 100 ways of cutting fuel use, including more efficient fuel use and reducing the<br />

weight on its planes. The company also announced it is slowing speeds and reducing the weight<br />

on some of its airplanes. The airline said that slowing planes by about 10km/h would cut its<br />

annual fuel bill by EUR 1m and only adds a minute or two to flight times. Brussels Airlines is<br />

also trying to force through changes in the air system. The current system often forces planes<br />

to fly a zigzag route over Europe as they pass over different countries’ airspaces. The situation<br />

in the European airline industry can get worse over the next months when airlines’ oil hedging<br />

ends and they will have to pay the full oil market rate.<br />

The EU has approved in-flight mobile calls<br />

The European Commission opened the way for<br />

airlines to introduce technology that would allow<br />

passengers to use their mobile phones throughout<br />

Europe’s airspace. The decision will enable calls, text<br />

messaging, and emails by GSM technology. The final<br />

decision to introduce in-flight mobile calls will<br />

be left to individual airlines. Some of them launched<br />

a trial of in-flight mobile phone services on Euro-<br />

pean routes. British Midland Airways, Portugal’s<br />

TAP, and the low-cost airline Ryanair are planning<br />

to offer services later this year. However, not all<br />

airlines support the EU’s plans. Lufthansa said in<br />

a statement that it is not interested in introducing<br />

the service because a majority of its customers see<br />

no need for phone calls during flights. Virgin also<br />

expressed reservations over the idea. EU officials say<br />

the cost of calls will be set by operators and the European<br />

Commission will keep a close eye to ensure<br />

that pricing is transparent. Passengers will be able to<br />

make and receive calls using a base station within the<br />

airplane. They will be allowed to turn their phones<br />

on after the plane reaches 3,000 meters, when other<br />

electronic devices such as laptops are permitted. The<br />

phone services will not be available during takeoff,<br />

landing or during turbulence, and the captain or<br />

crew of the plane can control when they want to<br />

switch off the onboard network.

Deutsche Bahn’s<br />

partial privatization agreed<br />

Germany’s committee of government parties coalition sealed an agreement that paves the way for<br />

the partial privatisation of the last major state-owned company in Germany, the national train operator<br />

Deutsche Bahn. Chancellor Angela Merkel’s conservatives (CDU/CSU) and her Social Democrat<br />

(SPD) partners agreed that 24.9% of the company’s passenger and freight divisions will be sold to private<br />

investors via an initial public offering. All stations, tracks (34,000 kilometres) and energy supplies<br />

will still be owned by the state. The sale is expected to net between EUR 5 billion and EUR 8 billion.<br />

“Deutsche Bahn is a very special company and it can’t be compared to others. It is a safe investment<br />

that promises long-term success, both in terms of profits and the value of the stock itself. I am sure<br />

investors will come,” said Wolfgang Tiefensee, Federal <strong>Transport</strong> Minister. Furthermore, he said the<br />

government hoped the Bahn’s initial public offering could take place before the end of <strong>2008</strong>, but he<br />

added that “one could perhaps wait two or three months” if market conditions prove unfavourable.<br />

According to SPD leader Kurt Beck, two thirds of the money will be invested to finance growth plans<br />

of the rail and logistics giant. The rest will go back into the general government budget. The coalition<br />

agreement comes after months of wrangling between Germany’s governing parties over how much of<br />

the company should be privatized. Merkel’s conservatives said they want this initial privatization to be<br />

the first step toward selling off up to 49.9% of Deutsche Bahn.<br />

PKP Cargo will develop container transport<br />

Rails for the high speed lines<br />

Corus Rail, a company providing products<br />

and infrastructure services to the international<br />

rail industry, supplied the rails for the TGV<br />

high-speed train tracks. For the new East TGV<br />

line, Corus supplied 300 km of high-speed<br />

line, plus 44 km of tracks to link the new line<br />

to the classic network. In all, 1,300 km of 60E1<br />

rails (60 kg per metre) were supplied, in unit<br />

lengths of 80 m. The total weight of this order<br />

amounts to 78,000 tons of steel, i.e., eight times<br />

the weight of the Eiffel Tower. At more than<br />

300 kph in commercial operation, and over<br />

550 kph for the speed record, rail straightness<br />

has to meet very stringent requirements. The<br />

Despite Poland’s poor railway infrastructure,<br />

which does not allow trains to develop their proper<br />

speed, and high track access fees charged by the<br />

national rail infrastructure company PKP PLK,<br />

the Polish state-owned rail freight operator PKP<br />

Cargo expects that container rail transport in Poland<br />

will grow by 30% on an annual basis over the<br />

next few years. To face up to the growing market<br />

demand, the company is going to buy 800 container<br />

carriages this year to increase its total number<br />

to 3,000 by 2010. Furthermore, PKP Cargo will<br />

invest in modernization of the existing cargo terminals<br />

and in construction of new ones. By 2010,<br />

the company plans to operate at least eight logistics<br />

centres and container terminals. PKP Cargo’s<br />

target is to increase the share of the intermodal rail<br />

freight services in Poland from 2.5% in 2006 to<br />

10%, which is the average level in Western Europe.<br />

In 2007, PKP Cargo’s container transport division<br />

transported 512,000 TEU and achieved a growth<br />

of over 27%, year-on-year.<br />

vertical deviations authorized, for example, are<br />

set at 0.3 mm over a distance of 3 m, which is<br />

four times less than on a conventional track. In<br />

the rail production chain it was necessary to<br />

ensure perfect geometry, eliminate all impurities<br />

from the steel, and guarantee the chemical<br />

and mechanical homogeneity of all the rails<br />

made for high-speed tracks. Rail measurements<br />

and straightness were checked using<br />

laser systems; the absence of surface defects<br />

was controlled by using eddy currents and the<br />

internal structure had to be inspected using ultrasonic<br />

systems. The service life of TGV rails<br />

is 20 to 30 years.<br />

Hinterland<br />

What’s new?<br />

The Russian Railways (RŽD) directed a<br />

proposal to the Russian government about<br />

two increases in the tariffs on cargo transportations.<br />

According to RŽD representatives,<br />

the first increase by 5% will compensate<br />

the increase in prices due to inflation.<br />

The second is projected for the period<br />

from <strong>2008</strong> to 2011: by 3.6% in <strong>2008</strong>, by 7%<br />

in 2009, by 9% in 2010 and by 6% in 2011.<br />

These funds will be directed towards the<br />

company’s planned investment projects.<br />

PCC Rail, the second-largest private<br />

freight rail operator in Poland, decided to<br />

establish a new subsidiary called PCC Logwag,<br />

which will manage and administrate<br />

PCC Rail’s rolling stock. The company will be<br />

100% owned by PCC Rail, and will start operating<br />

from 1 July <strong>2008</strong>. Actually, PCC Rail<br />

Group plans to invest in foreign markets. The<br />

joint venture company will be established<br />

soon in the Czech Republic. At the beginning<br />

of 2009, a similar company will start its<br />

services in Bulgaria and in Austria.<br />

PKP Group, the Polish national railway operator,<br />

earned its first-ever net profit of EUR<br />

22m last year, compared to a loss of EUR<br />

68m in 2006. It is a result of lower costs,<br />

which fell by EUR 172m and 8m more passengers<br />

served in comparison with 2006.<br />

The company’s income amounted to EUR<br />

3.2 billion. In <strong>2008</strong>, a similar result is expected<br />

to be achieved.<br />

The European Commission adopted a<br />

European standard for train signalling and<br />

speed control – the European Train Control<br />

System (ETCS) – which guarantees a<br />

common standard that enables trains to<br />

cross national borders and enhances safety.<br />

Currently, there are more than 20 different<br />

signalling systems operating in Europe and<br />

their incompatibility is a major technical<br />

barrier to international traffic. Thanks to the<br />

ETCS, freight volume is expected to increase<br />

by 55% along certain corridors and travel<br />

time is expected to be reduced by 20%.<br />

Veolia Cargo, the rail-based logistics<br />

company, signed an agreement for the<br />

acquisition of Rail4Chem which specializes<br />

in international rail freight transportation.<br />

The takeover will make Veolia Cargo<br />

one of Europe’s largest private rail freight<br />

companies, with revenues of more than<br />

EUR 200m and will expand its Dutch and<br />

German business.<br />

3/<strong>2008</strong> | <strong>Baltic</strong> <strong>Transport</strong> <strong>Journal</strong> | 13

TRANSPOREON<br />

SOLUTIONS FOR E-LOGISTICS<br />

A meeting of logistics<br />

decision-makers!<br />

Networks and the use of intelligent<br />

logistics solutions are increasingly<br />

becoming a critical success factor<br />

when the competition is tough.<br />

Hear directly from the logistics decisionmakers<br />

at Whirlpool Polar S.A., PLI<br />

Sp. z o.o. and Curver Poland Sp. z o.o.,<br />

about how they have dramatically<br />

accelerated their logistics.<br />

Discuss the challenges of accelerated<br />

logistics, network and make new<br />

professional contacts in an exclusive<br />

atmosphere.<br />

Register now free of charge for the<br />

shipper-event 1st e-logistics networking.<br />

More information, programme and<br />

registration are available at:<br />

www.transporeon.pl<br />

Partner Magazines:<br />

Rynek Chemiczny - Logistyka - <strong>Baltic</strong> <strong>Transport</strong><br />

<strong>Journal</strong> - Spedycja <strong>Transport</strong> Logistyka - Flota<br />

Auto Biznes - Truck&Business - Eurologistics<br />

- CEO - CFO - MM Magazyn Przemysłowy<br />

- Materiały Sypkie i Masowe - Ciężarówki<br />

Partner Web portals:<br />

4transport.pl Logistyka.net.pl - etransport.<br />

pl - logisticus.com.pl - nowoczesnafirma.pl -<br />

e-biznes.pl - wp.pl - towaryniebezpieczne.pl -<br />

Money.pl<br />

Just one question<br />

Overinvestment?<br />

Do you agree that mega-ports are overinvested and that upgrading<br />

small and medium-sized ports could lead to greater<br />

effectiveness?<br />

In the last issue of the <strong>Baltic</strong> <strong>Transport</strong> <strong>Journal</strong> we published an article by Per Olaf Brett<br />

entitled “The mega-port development mania must be stopped”. In this article (available<br />

to read on www.baltictransportjournal.com) the author argues that the percentage of<br />

investments in mega-ports is much higher than their share in European maritime freight<br />

handling. Moreover, they are not effective, in terms of providing uninterrupted cargo flow,<br />

especially with the hinterland. In Brett’s opinion it’s strong political pressure and not commercial<br />

reasons that drive ports towards further developement. This drives the author towards<br />

a call for stopping overinvestments, reducing modal shifts of cargo, retaining cargo onboard,<br />

decentralisation and strengthening the role of small and medium-sized ports.<br />

The article received a wide response among our readers and is now the subject of our main<br />

question in this issue.<br />

14 | <strong>Baltic</strong> <strong>Transport</strong> <strong>Journal</strong> | 3/<strong>2008</strong><br />

We are not overinvested<br />

Bengt van Beuningen<br />

Port of Hamburg Marketing<br />

The hub and spoke system in Europe is working well. Big ports function<br />

as hub ports and the smaller ports are serviced by feeder/short sea traffic.<br />

Both smaller and bigger ports must invest and bring up their infrastructure<br />

and facilities to become ready for further cargo growth.<br />

Liner vessels do not have to wait for port access in Hamburg or for terminal<br />

service. Hamburg was just voted as a fast and good service port with a<br />

high quality network for hinterland traffic by the shipping lines.<br />

We just decided to invest EUR 3 billion to bring up port terminals and<br />

infrastructure because we expect to handle around 18 million TEU in<br />

2015. The terminal operators (private companies) will invest around<br />

EUR 3 billion to modernize and extend their facilities. This is a private<br />

investment which we cannot forbid.<br />

Wait for the climate change and see<br />

Hans Hansson<br />

Freight Commercial Manager at Stena Line Freight<br />

My view is that the mega ports are effective up to a certain level and,<br />

beyond that point, new cost elements emerge that will be counterproductive.<br />

One thing is to grow the port itself but what we see today<br />

is that many of the mega-ports are fighting with an insufficient hinterland<br />

infrastructure. There will be a need for mega-ports (specialized)<br />

around the world but mainly then as hubs for the mega carriers<br />

(more than 10,000 TEU) from which the containers are feedered to<br />

smaller ports. What we see today is the fact that many of the smaller<br />

and medium-sized ports are more competitive and flexible in their<br />

servicing than the real big ones.<br />

For the time being, we see an enormous overinvestment in ports all<br />

over the world which will influence the effect of climate change on a<br />

new possible routing. The North-West passage will save a lot of time<br />

and fuel.

Where can we develop our next project?<br />

Johannes de Jong<br />

CEO of <strong>Baltic</strong> Container Terminal, Gdynia<br />

I read with interest the ideas expounded in Per Olaf Brett’s article,<br />

which appeared in <strong>BTJ</strong> 2/<strong>2008</strong>.<br />

The headline employed is perhaps a little radical for the<br />

beliefs expressed which seemed to suggest a change in<br />

emphasis from major hub port development to small and<br />

medium-sized regional ports as a solution to meet future<br />

transport system and capacity requirements. While the article<br />

does suggest something of a major change in direction<br />

in development terms, it does not, however, entirely rule out<br />

future development in the major hub ports and to this extent<br />

it acknowledges there are “horses for courses.”<br />

It is clear that the commercially-oriented interests that have<br />

moved into the sector – independent international terminal<br />

operators, shipping lines, investment banks and others<br />

– now represent a key driving force in port development. Today<br />

over 80% of the world’s container handling capacity is<br />

in the hands of the major international terminal operators.<br />

Some of the statements used in the article appear to suggest<br />

port growth and investment are still based on regional<br />

It’s customers who prefer mega-ports<br />

Lars Karlsson<br />

Managing Director, Copenhagen Malmö Port AB<br />

My direct comment is: “We have heard it all before!” And, I get<br />

the feeling when I read this article that there is a call for more<br />

regulations and “EU – Port Packages”. It lacks recognition<br />

of the market forces and market orientation. Logistics and<br />

transports are no longer a matter of a “planned economy”<br />

where politicians decide where cargo shall be handled and<br />

on what terms or rates.<br />

The mega-ports are of course there because they are<br />

needed! But there are, of course, always limits to the extent<br />

that they can grow. Surrounding infrastructure is<br />

normally the limiting factor but the trend is very clear:<br />

the larger ports will get larger and the smaller ports<br />

Investments are necessity<br />

Annick Dekeyser<br />

Marketing Executive, Antwerp Port Authority<br />

I cannot really agree with the opinion that big ports are over-investing<br />

in capacity. We have globalisation and growing trade.<br />

The goods need to come to Europe. In your local supermarket you<br />

would like to buy your exotic fruit, and you would like to use electronic<br />

equipment made in China. We do need to have the capacity<br />

so vessels can come to a port and unload their goods without<br />

any problems. In Antwerp we have invested in a new container<br />

dock. This was a big investment but I wouldn’t say it was an overinvestment.<br />

It was simply an answer to a need.<br />

I can assure you that we are also working on hinterland<br />

connections. We develop the railways, inland navigations,<br />

and the infrastructure for roads. In Antwerp there is a group<br />

of people who is working very hard to optimise all kinds of<br />

hinterland connections.<br />

We cannot deny the fact that cargo flow into Europe is uneven.<br />

For instance, almost all import is coming through the port of<br />

Rotterdam while all exports are going through the port of Ant-<br />

Just one question<br />

and/or political considerations but I would contend such<br />

views are not in line with reality. The global operators are<br />

growing because they know how to evaluate good projects<br />

by looking at important issues such as inland infrastructure,<br />

cultural and labour environment, legal and environmental<br />

obligations, etc. And, as the parent group of my<br />

own company proves – ICTSI – the focus is not just on large<br />

port developments.<br />

Mega-ports, mainly based on hub and spoke for the global<br />

carriers, will continue to grow as long as global trade will<br />

grow and there is enough draft and inland infrastructure.<br />

Small ports and terminals will also continue to advance and,<br />

particularly, as the demand for capacity strengthens. Dedicated<br />

short-sea services need their customized gateways.<br />

Therefore, the question is not what needs to be stopped.<br />

The question for many global port and terminal operators<br />

is, “where can we still develop our next project?” And, leave<br />

mega or small, any will do! If you still know one, please contact<br />

the writer.<br />

will get smaller and probably specialised or niched to<br />

certain commodities.<br />

The European port and terminal industry is nowadays very<br />

market-oriented and operates on commercial grounds and<br />

responds to market forces. In general terms the author argues<br />

that “port and terminals should improve their ships’ turnaround<br />

times, opening hours and improve their overall flexibility.”<br />

But, in order to accomplish this, you need to be big! It is<br />

not possible to operate a port and terminal 24/7 at economic<br />

competitive rates without very large volumes. Finally, it is not<br />

the ports and terminals that set the production levels. Always<br />

remember that the port and terminal operator supplies the<br />

production resources and the shipping company supplies the<br />

production conditions.<br />

My view is that large ports will grow larger and small will get<br />

smaller and some might even disappear.<br />

werp. This causes imbalance. Railway operators have problems<br />

with empty trains and cannot deliver shuttle services which can<br />

be provided only when they are profitable both ways. We bring<br />

together all kinds of parties like shipping companies, railway<br />

companies, forwarders, and ask them to guarantee a certain<br />

amount of products and a certain volume. This is one of the efforts<br />

of the Port Authority, playing the mutual role by stimulating<br />

this kind of thing. Right now we are primarily the last port of<br />

call for vessels going to the Far East so we are trying to convince<br />

the shipping companies to make us their first port of call when<br />

they return to Europe.<br />

Shipping companies have plans to build bigger and bigger<br />

vessels. I don’t think that ports’ infrastructure can cope with<br />

it any longer. Ports do not have unlimited draft, they have<br />

to dredge constantly to make it safer for the ships. This is extremely<br />

expensive. Another issue is that big vessels tend to arrive<br />

in ports on Friday afternoons or on Mondays – all at the<br />

same time. And then we have congestion problems again.<br />

With smaller vessels you have the possibility to make more<br />

frequent calls which in turn lessens enormous delays.<br />

3/<strong>2008</strong> | <strong>Baltic</strong> <strong>Transport</strong> <strong>Journal</strong> | 15

Event<br />

TransRussia <strong>2008</strong><br />

Big country, promising market<br />

Photo: Agnieszka Selig<br />

With its territory of 17m km 2 , 11 time zones and a distance of over<br />

9,000 km between its western and eastern border, Russia certainly<br />

is a challenge for transport and logistics companies of all kinds.<br />

Especially since a lot of freight<br />

is transported in and out of<br />

the country. The recent export<br />

boom of oil and gas from the<br />

Russian Federation resulted in<br />

huge investments both in the<br />

extractive industry and in the transport infrastructure<br />

of all kinds. It is estimated that<br />

the private sector invests USD 120-150 billion<br />

in the Russian transport and logistics<br />

market each year. Besides this, Russia’s fast<br />

economic growth (more than 7% in 2007),<br />

corresponding with this boom, causes a<br />

large import of consumer goods.<br />

Although Russia is still not as an important<br />

trading partner for the EU as China,<br />

certainly it’s widely recognized as one of the<br />

most promising markets in the world. Hence,<br />

everybody wants to be there.<br />

No wonder this year’s TransRussia exhibition<br />

was the biggest ever, with over 520 exhibitors<br />

(The <strong>Baltic</strong> <strong>Transport</strong> <strong>Journal</strong> among<br />

them) from 26 countries. This year, for the<br />

first time, it was organized in the modern and<br />

spacious Expocentr Fairgrounds at the banks<br />

of the River Moscow.<br />

Six countries – Germany (with over 60<br />

companies presenting their achievements at a<br />

joint stand), Finland, Lithuania, Latvia, Estonia<br />

16 | <strong>Baltic</strong> <strong>Transport</strong> <strong>Journal</strong> | 3/<strong>2008</strong><br />

and Spain – had their national pavilions. Latvia,<br />

Lithuania and Finland, with their seaports close<br />

to the Russian borders, are the countries that<br />

Photo: Agnieszka Selig<br />

Rodan Šenekl, Commercial Director and<br />

Member of the Directors Board, CD Cargo,<br />

a.s. reading <strong>BTJ</strong>.<br />

benefit the most from sea trade with their eastern<br />

neighbour. The Finnish port of Kotka has<br />

become a kind of container hub for Far East<br />

imports to Russia, while the <strong>Baltic</strong> Republics’<br />

ports – in spite of some obstacles – still remain<br />

an important gateway to the Russian market.<br />

One of the sessions during the 13 th International<br />

<strong>Transport</strong> and Logistic Conference accompanying<br />

TransRussia <strong>2008</strong>, was devoted to<br />

container transportation in the <strong>Baltic</strong>. According<br />

to Raido Rebane of Green Carrier, 70% of<br />

Chinese logistics operators still believe that it’s<br />

easier to use <strong>Baltic</strong> ports on their way to Russia.<br />

Thus, some big investments are expected<br />

there, like the one by the Port of Ningbo in<br />

Tallinn’s Muuga terminal.<br />

One of the main topics discussed during<br />

the conference was the possible future development<br />

of the railway transport in Russia.<br />

The famous transsiberian-line is the shortest<br />

land-bridge between Europe and China. Successful<br />

transit of the Beijing-Hamburg Container<br />

Express in January of this year only<br />

whetted appetites. But the capacity of the<br />

line, as well as the efficiency of the whole existing<br />

railway infrastructure, is not sufficient<br />

enough. That’s why a long-term strategy for<br />

railway development has been implemented.<br />

By 2030, 20,000 km of new railways will be<br />

added to the already existing 85,000 km.<br />

Railway industry was surely a vivid part of<br />

this year’s Moscow event with Polish major national<br />

operators, PKP Cargo and PKP LHS as<br />

well as the leading railway forwarding company<br />

Trade Trans. The huge stands of the Chech<br />

(ČD Cargo) and Slovak Railways (ŽSSK), the<br />

Finnish VR Cargo, the Latvian Latvijas Dzelcels,<br />

the Lithuanian and Estonian national<br />

operators or Rail Cargo Austria - all gathered<br />

much attention along the exhibition.<br />

Some of the hindrances to the transport<br />

development in Russia were also mentioned.<br />

One of the most important is bureaucracy, like<br />

complicated customs-clearance rules that slow<br />

down cargo flow. It was widely recognized not<br />

only by representatives of foreign companies<br />

but by the hosts as well. But will their opinions<br />

be taken into account by the government? One<br />

of the rumours heard at TransRussia was that<br />

Vladimir Yakunin, head of Russian Railways<br />

(RŽD), will be the new transport minister in<br />

Vladimir Putin’s cabinet. Can he speed up the<br />

process of Russia’s integration with its neighbours<br />

on a transport level?<br />

Dariusz Szreter

This would have left the ports governed<br />

by the basic principles of the<br />

Treaty and secondary legislation.<br />

The essential question was<br />

whether it was in the interest of the<br />

ports to be subject to an incoherent<br />

patchwork of jurisprudence and legislation<br />

which often demonstrated contradictions, the<br />

conflicting objectives of the EU transport and<br />

environmental policy being a case in point.<br />

Beyond the traditional context<br />

Already in 2004, ESPO made a plea for a<br />

thorough reflection of the priorities to a European<br />

seaport policy, expressing the need for a<br />

coherent framework within a broad perspective<br />

focusing on the main challenges of the port sector.<br />

The time for such a profound discussion only<br />

became pertinent after the failure of the second<br />

Directive proposal. Several factors helped to<br />

bring the debate back on its feet. First there was<br />

the determination of <strong>Transport</strong> Commissioner<br />

Jacques Barrot to restore a climate of confidence<br />

after the traumatic experience of the Directive.<br />

Second the Commission had launched a process<br />

to develop a comprehensive and integrated<br />

maritime policy which would inevitably cover<br />

ports. Finally there came a proposal from ESPO<br />

to organize a wide-ranging stakeholders consultation<br />

on the principal themes and challenges<br />

to the European ports’ policy. The latter two<br />

broadened the scope of the debate beyond the<br />

traditional transport policy context.<br />

Between June 2006 and June 2007, a stakeholder<br />

consultation process was held which<br />

consisted of two conferences and six thematic<br />

workshops. This resulted in adopting the communication<br />

policy on European ports by the<br />

Commission on 18 October 2007. The communication<br />

resorts to the Commission’s integrated<br />

maritime policy and forms part of<br />

its freight transport agenda, which were both<br />

adopted around the same time.<br />

Balanced picture reflected<br />

The Commission’s new communication<br />

is based on an overview of the general challenges<br />

to the European ports’ system. These include<br />

the demand for international transport,<br />

technological change, emissions and climate<br />

Maritime<br />

A new policy for the European seaports<br />

No traffic flow reorientation<br />

Following the failure of the second port services’ Directive in<br />

2006, it looked for a while as though the prospect of a European<br />

ports’ policy was definitely off the table.<br />

change, dialogue between the ports, cities and<br />

stakeholders and, finally, reconciliation with<br />

transparency, competition and, in general, the<br />

Community’s set of rules.<br />

The communication’s actual policy proposals<br />

generally consist of a mixture in interpreting<br />

the Treaty rules and an action plan<br />

with further measures and instruments, which<br />

are mostly of a “soft law” nature, i.e., which are<br />

not legally binding but have certain indirect<br />

legal effects and aiming to produce practical<br />

effects. These relate to the following areas:<br />

port performance and hinterland connections,<br />

expanding capacity while respecting the environment,<br />

modernisation, a level playing field<br />

– clarity for investors, operators and users, establishing<br />

a structured dialogue between the<br />

ports and cities and, finally, work in ports.<br />

ESPO has given a positive response to the<br />

Commission’s communication. We believe the<br />

new policy generally reflects the balanced picture<br />

that emerged from the stakeholders consultation.<br />

We have also welcomed the broad perspective<br />

of the communication which included<br />

topics such as capacity expansion and port-city<br />

relations, which were never thoroughly discussed<br />

at a European level despite their vital importance<br />

for many ports on the continent. ESPO<br />

agrees with the general focus of the communication<br />

on soft law measures and instruments,<br />

which complement the diversity of European<br />

ports better than stringent legislation.<br />

Let the market find its solutions<br />

In this respect, we especially appreciate the<br />

Commission’s recognition of the pivotal role of<br />

port authorities, notably with regard to the use<br />

of concessions. Defined in a broad sense, concessions<br />

are very useful governance instruments for<br />

public landlord port authorities and often the<br />

only tools they have at their disposal to protect<br />

the legitimate interests of their ports. The interpretation<br />

given by the Commission broadly<br />

corresponds to the principles we believe port<br />

authorities should apply when granting concessions,<br />

i.e., in regard to selection criteria, durations<br />

as well as performance, and ownership clauses.<br />

ESPO is currently undertaking a study on how<br />

European port authorities are using concession<br />

instruments. The results will be presented at our<br />

annual conference to be held in Hamburg on<br />

Patrick Verhoeven is the Secretary General,<br />

the European Seaports Organisation<br />

(ESPO).<br />

May 29-30, <strong>2008</strong>. The results may lead to further<br />

comments and initiatives at a later stage.<br />

ESPO has also welcomed the fact that the<br />

Commission is not seeking to develop measures<br />

which would alter the distribution of traffic across<br />

Europe. The market, in combination with policies<br />

of regional and national authorities, is largely capable<br />

of finding its own solutions. The European<br />

port scene is indeed becoming more diverse in<br />

terms of the number of ports involved along with<br />

the scope of port functions and services which, in<br />

turn, are leading to more routing options for shippers.<br />

It is our belief that the Commission should<br />

refrain, now and in future, from any interventionist<br />

policies which, directly or indirectly, aim at reorienting<br />

traffic flows in Europe.<br />

Finally, we look forward to continuing the<br />

constructive dialog with the services of the Commission<br />

and other stakeholder organizations on<br />

the instruments and measures which are announced<br />

in the communication. ESPO is particularly<br />

interested in contributing to the guidelines<br />

on the application of Community environmental<br />

legislation to port development and State aid<br />

guidelines.<br />

Patrick Verhoeven<br />

Find more on this<br />

topic at TOC Europe<br />

Conference,<br />

17-19 June in Amsterdam,<br />

where<br />

Mr Verhoeven will<br />

be a panelist in the<br />

plenary session: The Outlook for Europe.<br />

3/<strong>2008</strong> | <strong>Baltic</strong> <strong>Transport</strong> <strong>Journal</strong> | 17

Maritime<br />

Vuosaari project in its final stage<br />

The return of the city<br />

For ages ports gave rise to the development of<br />

the cities always having a definite impact on<br />

their economies.<br />

Usually they were an integral part of the city centre being an<br />

excellent job provider and an appealing location for businesses<br />

and investment.<br />

The Industrial Revolution, technical and technological<br />

improvements, trade development and the change in<br />

its pattern presented new challenges. The ports started to<br />

expand beyond the city limits becoming more alienated from the city itself.<br />

This process was uninterrupted till the mid-20th century when we could observe<br />

new concepts in the port and city co-existence; one result was a new<br />

demand for larger and specialized port terminals with an adequate capacity.<br />

The old port areas returned to the city as business, cultural, and publiclike<br />

new multifunctional districts. The city of Helsinki is an example of the<br />

port-town metamorphosis benefiting both the harbour itself, industrial businesses<br />

involved, and the city development as well.<br />

The beginning<br />

In the last years of the 20 th century the City Hall of Helsinki started a<br />

project whose aim was to create a new highly specialized harbour in place of<br />

the old one, located in the city centre. Only passenger, cruise, and ferry shipping<br />

were to remain in the old port. The first step taken was the relocation<br />

of the Ruoholahti harbour, a terminal which served as a discharging base<br />

for imported coal for two main power plants: Samisaari and Hanasaari. The<br />

Ruoholahti district is located roughly 2 km from the very centre of Helsinki,<br />

and in the past the area was almost entirely dedicated for industrial functions.<br />

Along with the city’s expansion, the coal port was beginning to be<br />