Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

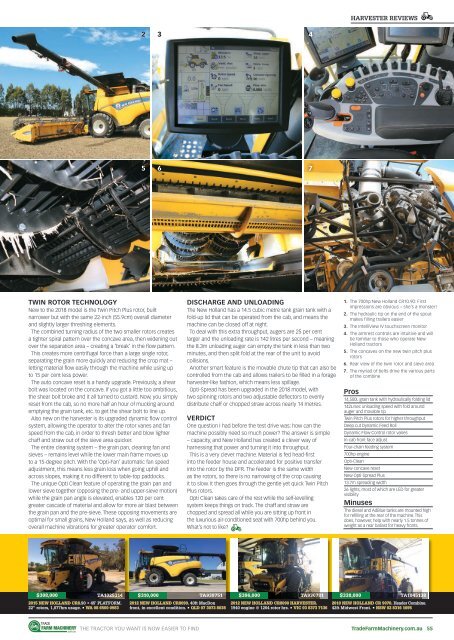

HARVESTER REVIEWS<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

TWIN ROTOR TECHNOLOGY<br />

New to the 2018 model is the Twin Pitch Plus rotor, built<br />

narrower but with the same 22-inch (55.9cm) overall diameter<br />

and slightly larger threshing elements.<br />

The combined turning radius of the two smaller rotors creates<br />

a tighter spiral pattern over the concave area, then widening out<br />

over the separation area – creating a ‘break’ in the flow pattern.<br />

This creates more centrifugal force than a large single rotor,<br />

separating the grain more quickly and reducing the crop mat –<br />

letting material flow easily through the machine while using up<br />

to 15 per cent less power.<br />

The auto concave reset is a handy upgrade. Previously, a shear<br />

bolt was located on the concave. If you got a little too ambitious,<br />

the shear bolt broke and it all turned to custard. Now, you simply<br />

reset from the cab, so no more half an hour of mucking around<br />

emptying the grain tank, etc. to get the shear bolt to line up.<br />

Also new on the harvester is its upgraded dynamic flow control<br />

system, allowing the operator to alter the rotor vanes and fan<br />

speed from the cab, in order to thresh better and blow lighter<br />

chaff and straw out of the sieve area quicker.<br />

The entire cleaning system – the grain pan, cleaning fan and<br />

sieves – remains level while the lower main frame moves up<br />

to a 15-degree pitch. With the ‘Opti-Fan’ automatic fan speed<br />

adjustment, this means less grain loss when going uphill and<br />

across slopes, making it no different to table-top paddocks.<br />

The unique Opti Clean feature of operating the grain pan and<br />

lower sieve together (opposing the pre- and upper-sieve motion)<br />

while the grain pan angle is elevated, enables 120 per cent<br />

greater cascade of material and allow for more air blast between<br />

the grain pan and the pre-sieve. These opposing movements are<br />

optimal for small grains, New Holland says, as well as reducing<br />

overall machine vibrations for greater operator comfort.<br />

DISCHARGE AND UNLOADING<br />

The New Holland has a 14.5 cubic metre tank grain tank with a<br />

fold-up lid that can be operated from the cab, and means the<br />

machine can be closed off at night.<br />

To deal with this extra throughput, augers are 25 per cent<br />

larger and the unloading rate is 142 litres per second – meaning<br />

the 8.3m unloading auger can empty the tank in less than two<br />

minutes, and then split fold at the rear of the unit to avoid<br />

collisions.<br />

Another smart feature is the movable chute tip that can also be<br />

controlled from the cab and allows trailers to be filled in a forage<br />

harvester-like fashion, which means less spillage.<br />

Opti-Spread has been upgraded in the 2018 model, with<br />

two spinning rotors and two adjustable deflectors to evenly<br />

distribute chaff or chopped straw across nearly 14 metres.<br />

VERDICT<br />

One question I had before the test drive was: how can the<br />

machine possibly need so much power? The answer is simple<br />

– capacity, and New Holland has created a clever way of<br />

harnessing that power and turning it into throughput.<br />

This is a very clever machine. Material is fed head-first<br />

into the feeder house and accelerated for positive transfer<br />

into the rotor by the DFR. The feeder is the same width<br />

as the rotors, so there is no narrowing of the crop causing<br />

it to slow. It then goes through the gentle yet quick Twin Pitch<br />

Plus rotors.<br />

Opti Clean takes care of the rest while the self-levelling<br />

system keeps things on track. The chaff and straw are<br />

chopped and spread all while you are sitting up front in<br />

the luxurious air-conditioned seat with 700hp behind you.<br />

What’s not to like?<br />

1. The 700hp New Holland CR10.90: First<br />

impressions are obvious – she’s a monster!<br />

2. The hydraulic tip on the end of the spout<br />

makes filling trailers easier<br />

3. The IntelliView IV touchscreen monitor<br />

4. The armrest controls are intuitive and will<br />

be familiar to those who operate New<br />

Holland tractors<br />

5. The concaves on the new twin pitch plus<br />

rotors<br />

6. Rear view of the twin rotor and sieve area<br />

7. The myriad of belts drive the various parts<br />

of the combine<br />

Pros<br />

14,500L grain tank with hydraulically folding lid<br />

142L/sec unloading speed with fold around<br />

auger and movable tip<br />

Twin Pitch Plus rotors for higher throughput<br />

Deep cut Dynamic Feed Roll<br />

Dynamic Flow Control rotor vanes<br />

In-cab front face adjust<br />

Four-chain feeding system<br />

700hp engine<br />

Opti-Clean<br />

New concave reset<br />

New Opti-Spread Plus<br />

13.7m spreading width<br />

26 lights, most of which are LED for greater<br />

visibility<br />

Minuses<br />

The diesel and AdBlue tanks are mounted high<br />

for refilling at the rear of the machine. This<br />

does, however, help with nearly 1.5 tonnes of<br />

weight as a rear ballast for heavy fronts.<br />

$308,000<br />

TA1025314<br />

2015 NEW HOLLAND CR8.90 + 45’ PLATFORM.<br />

22” rotors, 1,877hrs usage. • WA 08 6500 0983<br />

$310,000<br />

TA938751<br />

2012 NEW HOLLAND CR8090. 40ft MacDon<br />

front, in excellent condition. • QLD 07 3073 8038<br />

$396,000<br />

TA930781<br />

2012 NEW HOLLAND CR8090 HARVESTER.<br />

1940 engine @ 1264 rotor hrs. • VIC 03 8373 7136<br />

$338,000<br />

TA1045138<br />

2010 NEW HOLLAND CR 9070. Header Combine.<br />

42ft Midwest Front. • NSW 02 8316 1695<br />

THE TRACTOR YOU WANT IS NOW EASIER TO FIND Trade<strong>Farm</strong><strong>Machinery</strong>.com.au 55