CEAC-2021-07-July

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

The Morton Arboretum, in Lisle, is<br />

exhibiting 5 extraordinary pieces of<br />

larger-than-life sculptures from<br />

Daniel Popper.<br />

The pieces stand upwards of 40' and emote notions of nature,<br />

beauty, organic connections and depth.<br />

Popper is a multidisciplinary artist known globally for his organic,<br />

nature-inspired artwork, and the pieces on display now in<br />

Lisle are among the most spectacular.<br />

The local exhibit, Human+Nature, was the first time Popper had<br />

his massive pieces of art manufactured in China and shipped,<br />

with the intent of piecing them together like a massive jigsaw<br />

puzzle.<br />

The concrete was a unique blend, mixed with fiberglass and<br />

other materials to provide it with strength and durability. It had<br />

been painted in China, and all seemed well at first.<br />

But there was a problem.<br />

When Popper, from Cape Town, South Africa, started unpacking<br />

the components for his piece “Thrive,” he noticed that the<br />

paint was distressed.<br />

The paint was not uniform and was peeling. It was also dull and<br />

not representative of Popper’s vision.<br />

What To Do?<br />

Popper and his team started reaching out across the country<br />

to find some help. They had limited time and resources. They<br />

had their small team that was on a tight schedule assembling,<br />

painting and building Thrive and the other sculptures. They<br />

were short on time and manpower to begin with, and started<br />

searching for support.<br />

That’s when Chicago Corrosion Group came in. Recommended<br />

to reach out to Popper by an associate in Las Vegas, the owner,<br />

Warren Brand, texted the team. At first, Popper was asking for<br />

more labor to scrape and otherwise remove the paint. But after<br />

an onsite inspection, Brand recommended a different course of<br />

action.<br />

“The sculpture was erected,” said Brand, “but needed work.” The<br />

seams needed to be closed and the paint was in bad shape.”<br />

Brand presented options. The South African team had started<br />

using hand tools to try to remove the paint and hoped to be able<br />

to spot-repair it. Brand, however, recommended that in order to<br />

obtain a uniform appearance, and the longevity required for a<br />

3-year exhibit, all of the old paint needed to be removed.<br />

“We recommend to our clients overcoating existing paints and<br />

coatings all the time,” said Brand. “But that’s only after a close<br />

evaluation of the existing paint, to ensure it’s capable of accepting<br />

another coating. That wasn’t the case with Thrive. She<br />

needed a new paint job.”<br />

After much discussion and research, Brand recommended a<br />

relatively new type of surface preparation called vapor blasting.<br />

Most readers will be familiar with sandblasting, in which<br />

compressed air is forced out of a hose, and finally a nozzle, with<br />

a metering valve at the blast tank inserting various types of abrasives<br />

into the airstream.<br />

The abrasives can be nearly anything, from different size particles<br />

of sand, blast grit, steel shot, walnut shells, glass aggregate<br />

and garnet, to name a few.<br />

Abrasive blasting, or dry blasting, remains one of the most efficient<br />

and widely used ways to remove paint and prepare surfaces<br />

for paint and coatings. But there are problems — most notably,<br />

dust.<br />

Thrive was located amidst various paths and near a lake at the<br />

Arboretum. People were everywhere. And the work needed to<br />

be completed during the day.<br />

Vapor blasting, while similar in function, is different in one significant<br />

way — instead of using air as the medium to carry the<br />

aggregate, it uses high-pressure water vapor. The aggregate, as<br />

with dry abrasive blasting, is subject to numerous variables.<br />

A third method of blasting was considered: wet blasting. Wet<br />

blasting typically includes the metering of water into the airflow,<br />

(Continued on pg. 40)<br />

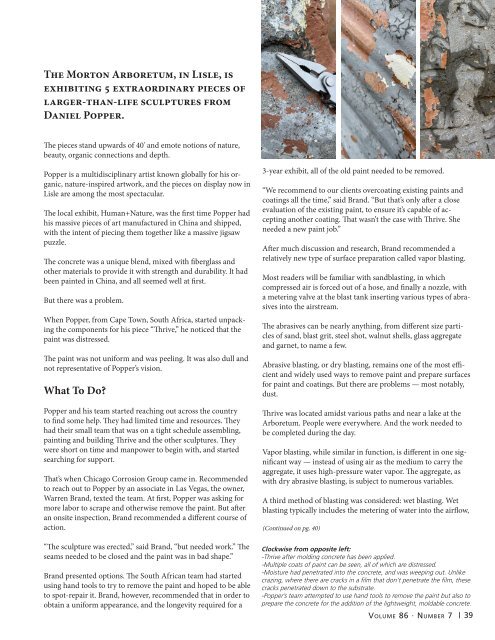

Clockwise from opposite left:<br />

-Thrive after molding concrete has been applied.<br />

-Multiple coats of paint can be seen, all of which are distressed.<br />

-Moisture had penetrated into the concrete, and was weeping out. Unlike<br />

crazing, where there are cracks in a film that don’t penetrate the film, these<br />

cracks penetrated down to the substrate.<br />

-Popper’s team attempted to use hand tools to remove the paint but also to<br />

prepare the concrete for the addition of the lightweight, moldable concrete.<br />

Volume 86 · Number 7 | 39