FALL 2021

Distributor's Link Magazine Fall 2021 / Vol 44 No 4

Distributor's Link Magazine Fall 2021 / Vol 44 No 4

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

64<br />

THE DISTRIBUTOR’S LINK<br />

Anthony Di Maio<br />

Anthony E. Di Maio attended Wentworth Institute and Northeastern University. In 1962 he<br />

started working with Blind Fasteners as Vice-President of Engineering & Manufacturing for two<br />

blind rivet manufacturers. He has been Chairman of the Technical Committee of the Industrial<br />

Fasteners Institute (IFI) and is still involved in the writing of IFI specifications. In 1991, he<br />

started ADM Engineering and is working with Fastener Manufacturers developing new fasteners<br />

and special machinery. He can be reached at ADM Engineering, 6 Hermon Ave., Haverhill, MA<br />

01832; phone and fax 978-521-0277; e-mail: tdimaio@verizon.net.<br />

SECONDARY MANUFACTURING OPERATIONS<br />

FOR BLIND RIVETS<br />

There are secondary manufacturing operations that<br />

must be performed to Structural blind rivets to make the<br />

Structural blind rivet perform correctly.<br />

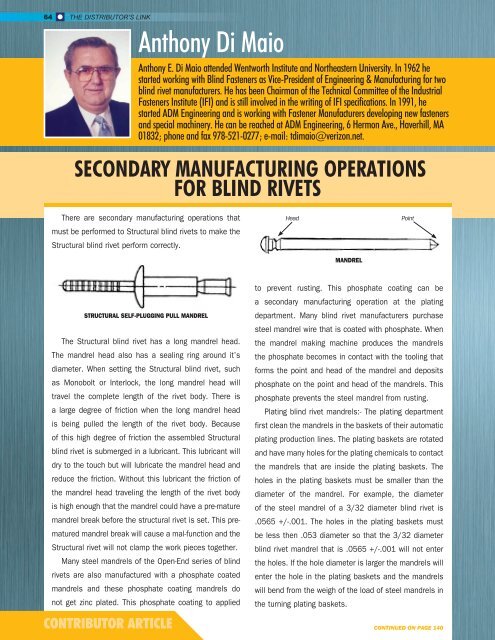

Head<br />

Point<br />

MANDREL<br />

STRUCTURAL SELF-PLUGGING PULL MANDREL<br />

The Structural blind rivet has a long mandrel head.<br />

The mandrel head also has a sealing ring around it’s<br />

diameter. When setting the Structural blind rivet, such<br />

as Monobolt or Interlock, the long mandrel head will<br />

travel the complete length of the rivet body. There is<br />

a large degree of friction when the long mandrel head<br />

is being pulled the length of the rivet body. Because<br />

of this high degree of friction the assembled Structural<br />

blind rivet is submerged in a lubricant. This lubricant will<br />

dry to the touch but will lubricate the mandrel head and<br />

reduce the friction. Without this lubricant the friction of<br />

the mandrel head traveling the length of the rivet body<br />

is high enough that the mandrel could have a pre-mature<br />

mandrel break before the structural rivet is set. This prematured<br />

mandrel break will cause a mal-function and the<br />

Structural rivet will not clamp the work pieces together.<br />

Many steel mandrels of the Open-End series of blind<br />

rivets are also manufactured with a phosphate coated<br />

mandrels and these phosphate coating mandrels do<br />

not get zinc plated. This phosphate coating to applied<br />

CONTRIBUTOR ARTICLE<br />

to prevent rusting. This phosphate coating can be<br />

a secondary manufacturing operation at the plating<br />

department. Many blind rivet manufacturers purchase<br />

steel mandrel wire that is coated with phosphate. When<br />

the mandrel making machine produces the mandrels<br />

the phosphate becomes in contact with the tooling that<br />

forms the point and head of the mandrel and deposits<br />

phosphate on the point and head of the mandrels. This<br />

phosphate prevents the steel mandrel from rusting.<br />

Plating blind rivet mandrels:- The plating department<br />

first clean the mandrels in the baskets of their automatic<br />

plating production lines. The plating baskets are rotated<br />

and have many holes for the plating chemicals to contact<br />

the mandrels that are inside the plating baskets. The<br />

holes in the plating baskets must be smaller than the<br />

diameter of the mandrel. For example, the diameter<br />

of the steel mandrel of a 3/32 diameter blind rivet is<br />

.0565 +/-.001. The holes in the plating baskets must<br />

be less then .053 diameter so that the 3/32 diameter<br />

blind rivet mandrel that is .0565 +/-.001 will not enter<br />

the holes. If the hole diameter is larger the mandrels will<br />

enter the hole in the plating baskets and the mandrels<br />

will bend from the weigh of the load of steel mandrels in<br />

the turning plating baskets.<br />

CONTINUED ON PAGE 140