You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

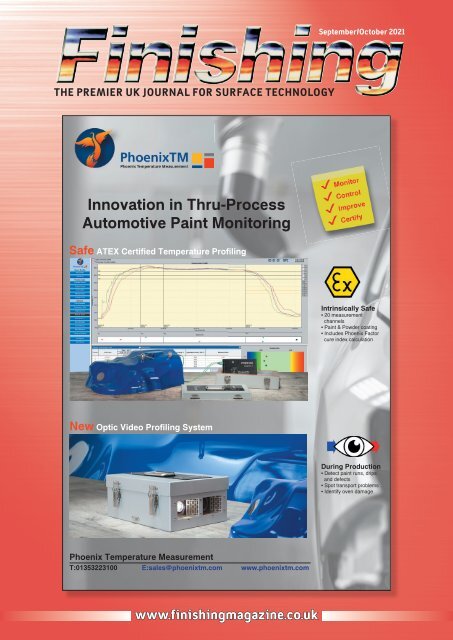

<strong>September</strong>/<strong>October</strong> <strong>2021</strong><br />

THE PREMIER UK JOURNAL FOR SURFACE TECHNOLOGY<br />

Innovation in Thru-Process<br />

Automotive Paint Monitoring<br />

Safe ATEX Certified Temperature Profiling<br />

Intrinsically Safe<br />

• 20 measurement<br />

channels<br />

• Paint & Powder coating<br />

• Includes Phoenix Factor<br />

cure index calculation<br />

New Optic Video Profiling System<br />

During Production<br />

• Detect paint runs, drips<br />

and defects<br />

• Spot transport problems<br />

• Identify oven damage<br />

Phoenix Temperature Measurement<br />

T:01353223100 E:sales@phoenixtm.com www.phoenixtm.com<br />

www.finishingmagazine.co.uk

THE<br />

MEMBERSHIP<br />

POWER<br />

OF<br />

THE SEA HAS ALL THE ATTRIBUTES YOU NEED<br />

Save money<br />

Save time<br />

Keep a step ahead with industry updates<br />

Enhance your reputation<br />

Gain political clout and expertise<br />

SURFACE<br />

ENGINEERING<br />

AWARDS<br />

FRIDAY 8 th OCTOBER <strong>2021</strong><br />

PARK REGIS BIRMINGHAM<br />

Visit www.sea.org.uk/<strong>2021</strong>-awards for<br />

sponsorship opportunities; if you wish<br />

to enter; or should you just wish to<br />

attend and support your industry.<br />

SEA SUPPORTS UK<br />

Want a low-cost way to take part in Advanced<br />

Engineering <strong>2021</strong>? The SEA has a dedicated area<br />

at the Advanced Engineering show, where we can<br />

showcase all that’s great about our industry.<br />

The SEA pavilion provides members with a focused<br />

area where they can exhibit for a subsidised price<br />

and is an excellent chance for companies to take<br />

full advantage of the networking and new business<br />

opportunities available, without breaking the bank.<br />

The exhibition takes place on Wednesday 3rd &<br />

Thursday 4th November <strong>2021</strong> at NEC, Birmingham<br />

and you can visit https://www.sea.org.uk/blog/<br />

advanced-engineering-<strong>2021</strong>/ for information on<br />

costs and what’s included in the package.<br />

To book a space within the SEA pavilion please<br />

contact us at info@sea.org.uk.<br />

Visit the members’ directory today to find a supplier or get help with your surface treatment requirements:<br />

https://www.sea.org.uk/member-directory/<br />

For further details of how the<br />

Surface Engineering Association<br />

can support you, please contact<br />

Michaella Mais on 0121 237 1123<br />

or email michaella.mais@sea.org.uk<br />

Surface Engineering Association<br />

Federation House<br />

10 Vyse Street Birmingham<br />

West Midlands B18 6LT<br />

+44 (0)121 237 1123<br />

info@sea.org.uk<br />

www.sea.org.uk<br />

A

www.finishingmagazine.co.uk CONTENTS 3<br />

Editor<br />

John Hatcher<br />

Tel: 01923 437618<br />

E.mail: j.hatcher@turretgroup.com<br />

Display Advertising<br />

Stewart Freshwater<br />

Tel: 01923 437615<br />

E.mail: s.freshwater@turretgroup.com<br />

Classified Advertising<br />

Stewart Freshwater<br />

Tel: 01923 437615<br />

E.mail: s.freshwater@turretgroup.com<br />

Production Manager<br />

Carol Baird<br />

Tel: 01923 437619<br />

E.mail: c.baird@turretgroup.com<br />

Managing Director<br />

Ian Garmeson<br />

Circulation<br />

Tel: 0141 370 3883<br />

circulation@dimensionsmail.co.uk<br />

Published by<br />

Turret Group Ltd<br />

Cardinal Point<br />

Park Road<br />

Rickmansworth,<br />

WD3 1RE<br />

Tel: +44 (0) 1923 432705<br />

Fax: +44 (0) 1923 432770<br />

Web: www.turretgroup.com<br />

Annual Subscription Rates<br />

United Kingdom: £144.00<br />

Overseas: £168.00 (Airmail)<br />

Printed by Stephens & George<br />

<strong>September</strong>/<strong>October</strong> <strong>2021</strong> – Volume 45 Number 5 – ISSN no. 0264 2506<br />

In this issue...<br />

As we roll into autumn it would be interesting to find out if the finishing industry is<br />

being affected by the lack of lorry drivers and staff in general. Hopefully this a short<br />

term issue, but there is also the knock on effect of inflation in all sectors of the<br />

economy, which is something we do not need as we continue to manage the pandemic<br />

and the consequences that it has had on our lives.<br />

In the news a new ‘colour of the year’ has been announced, plus there is the<br />

announcement of the BCF nominees for their awards. Good luck to all who have been<br />

nominated.<br />

I have also noticed that a number of shows in the industry are set to take place in the<br />

coming weeks, another sign that we are getting back to normal.<br />

This is great news, but let’s still stay safe out there!<br />

News<br />

Newsdesk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4<br />

Features<br />

Casting off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10<br />

Passed with flying colours . . . . . . . . . . . . . . . . . . . . .14<br />

Perfect polish . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16<br />

The latest ‘big win’ . . . . . . . . . . . . . . . . . . . . . . . . . . .22<br />

All members of the SEA<br />

automatically receive <strong>Finishing</strong> Magazine<br />

Peak performance . . . . . . . . . . . . . . . . . . . . . . . . . . .24<br />

Getting a top finish . . . . . . . . . . . . . . . . . . . . . . . . . .26<br />

All bases covered . . . . . . . . . . . . . . . . . . . . . . . . . . . .28<br />

Facts about fire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30<br />

Taking a shot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36<br />

© Copyright Turret Group Ltd <strong>2021</strong><br />

All Rights Reserved<br />

All rights reserved. No part of this publication<br />

may be produced in any material form (including<br />

photocopying it or storing it in any medium by<br />

electronic means and whether or not transiently<br />

or incidentally to some other use of this<br />

publication) without the written permission of<br />

the copyright owner except in accordance with<br />

the provisions of the Copyright, Designs and<br />

Patents Act 1988. Applications for the copyright<br />

owner's written permission to reproduce any<br />

part of this publication should be addressed to<br />

the info@turretgroup.com<br />

Regulars<br />

Installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20<br />

Workshop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46<br />

Classified listings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48<br />

<strong>Finishing</strong> (formerly <strong>Finishing</strong> Industries) was established in 1947 and incorporates Metal<br />

<strong>Finishing</strong> journal, Electroplating & Metal <strong>Finishing</strong>, The Plant Journal, Surface Coatings, and<br />

Industrial <strong>Finishing</strong> & Surface Coatings. <strong>Finishing</strong> is a member of the Metal <strong>Finishing</strong><br />

Association, a sustaining member of the Institute of Metal <strong>Finishing</strong> and the UK representative<br />

of the Groupement International des Revues de Traitements de Surfaces.<br />

<strong>Finishing</strong> – <strong>September</strong>/<strong>October</strong> <strong>2021</strong>

4 NEWS www.finishingmagazine.co.uk<br />

New colour of the year announced<br />

After stay-at-home orders and<br />

too few face-to-face moments<br />

over the last two years, people<br />

are craving authenticity, nature<br />

and meaningful human<br />

interaction after living in a<br />

mostly digital world. Introducing<br />

the Johnstone’s Trade by PPG<br />

Voice of Colour 2022 Colour of<br />

the Year: Olive Sprig (PPG1125-<br />

4) – a grounded, versatile and<br />

highly-adaptable grey-green,<br />

that represents optimism in a<br />

post-pandemic world, building<br />

on nature’s resilience.<br />

Voice of Colour’s Olive Sprig<br />

is a relaxed and enticing green<br />

that brightens any space, it is a<br />

flexible colour that lives well<br />

inside or outside, and blends in<br />

well with nearly any<br />

environment.<br />

“As many of us know<br />

following a year of lockdown,<br />

the easiest way to shift your<br />

mindset is to change your<br />

environment. While we begin to<br />

trade comfy clothing for our<br />

going-out gear, recipes at home<br />

for restaurant reservations, and<br />

a night in for a night out, our<br />

paint colour preferences are<br />

shifting too,” said Donna Taylor,<br />

PPG colour expert, Johnstone’s<br />

Trade. “People are growing tired<br />

of the stark, neutral palettes of<br />

yesterday and opting for colour<br />

in all forms. Call it rebellion, but<br />

we are certainly here for the<br />

resurgence of optimistic colours<br />

to guide us into a new era of<br />

home and commercial design.”<br />

Lending itself to be paired<br />

with natural materials, Olive<br />

Sprig looks effective alongside<br />

unique architectural elements<br />

and furniture with curved forms<br />

to create a comfortable and<br />

grounded space. The colour can<br />

help create a sanctuary in a<br />

bedroom or an office, and pairs<br />

with brass accents and wood<br />

tones on lower cabinets or other<br />

building features.<br />

Resilience, the need for<br />

connection and inspiration from<br />

nature were recurring themes at<br />

PPG’s Global Colour Forecasting<br />

Workshop. This annual event<br />

brings together more than 30<br />

PPG global colour stylists from<br />

the automotive, consumer<br />

electronics, aerospace, and<br />

home paint and stain industries.<br />

Over the course of several days,<br />

the stylists analyse the trends in<br />

lifestyles, demographics,<br />

geographies, global events and<br />

cross-cultural societal<br />

inspirations to determine what<br />

colours will resonate and<br />

represent the PPG global colour<br />

forecast, including the Voice of<br />

Colour 2022 Colour of the<br />

Year.<br />

HMG Paints supports defibrillator campaign<br />

HMG Paints is continuing its<br />

support of the Minutes Matter<br />

Campaign, alongside the British<br />

Coatings Federation and its<br />

members. The campaign has<br />

seen HMG Paints and other<br />

paint companies donate paint to<br />

the conversion of iconic red<br />

telephone boxes into lifesaving<br />

defibrillator stations.<br />

Community Heartbeat Trust<br />

and BT have been working<br />

together with rural communities<br />

to turn disused telephone boxes<br />

into Community Public Access<br />

Defibrillator sites or cPADs. The<br />

British Coatings Federation’s<br />

paint manufacturer members<br />

have stepped in to help preserve<br />

these iconic structures in<br />

communities, by arranging the<br />

donation of free paint and<br />

undercoat for renovation.<br />

Communities who want to<br />

convert their iconic telephone<br />

boxes into Community Public<br />

Access Defibrillator sites can visit<br />

www.minutesmatter.org.uk.<br />

“The whole world witnessed<br />

the importance of defibrillators<br />

during the Euro 2020<br />

championship and we’re proud<br />

to support the British Coatings<br />

Federation in partnership with<br />

the Community Heartbeat Trust<br />

and BT to promote the<br />

installation of defibrillators in BT<br />

phone boxes across the UK”<br />

commented John Falder, HMG<br />

Paints Chairman. “We were<br />

honoured to have provided paint<br />

for the first conversion in Long<br />

Wittenham and are elated that<br />

since then 668 further kiosks<br />

have been converted.”<br />

Through this campaign it is<br />

hoped to not only help save the<br />

lives of the 30,000 people who<br />

suffer cardiac arrest every year<br />

but to also preserve a part of our<br />

British heritage and culture, that<br />

is so well represented by the<br />

good old fashioned red<br />

telephone box.<br />

Ambitious<br />

acceleration<br />

The cycling accessories team at<br />

Rodi – the €30 million<br />

Portuguese manufacturer of<br />

aluminum rims and wheels –<br />

has found an innovative way of<br />

accelerating its environmental<br />

ambitions by switching from<br />

anodizing to a more sustainable,<br />

energy-efficient process using<br />

Interpon powder coatings from<br />

AkzoNobel.<br />

Rodi needed an alternative to<br />

anodizing that was durable,<br />

sustainable, and capable of<br />

delivering style with a lower<br />

gloss finish. The answer was a<br />

bespoke Interpon powder<br />

coating that delivers a smooth,<br />

soft ultra matt finish – with just<br />

3% gloss. It also comes with<br />

AkzoNobel’s X-Pro technology<br />

which delivers better protection<br />

against scratches, UV light and<br />

the weather.<br />

Rodi’s partnership with the<br />

Interpon team is built on a<br />

shared ambition to protect<br />

natural resources and reduce<br />

energy consumption. Rui<br />

Mendes, manager of Rodi’s<br />

Rims and Wheels business, says<br />

he already has plans to further<br />

increase production capacity<br />

with the team’s support: “It’s a<br />

formula that attracts the trust of<br />

some of Europe’s largest bicycle<br />

manufacturers including<br />

ACCELL, Pon Holdings and<br />

Decathlon,” he explains.<br />

“We are serving an<br />

environmentally conscious<br />

audience who are pushing a<br />

more sustainable agenda which<br />

we take very seriously. For us,<br />

this starts with the suppliers we<br />

work with and the products we<br />

use, and it is why we use<br />

Interpon.”<br />

The partnership began two<br />

years ago when AkzoNobel<br />

demonstrated how switching<br />

from a previous supplier to an<br />

Interpon 610 Low-E powder<br />

coating reduced Rodi’s energy<br />

consumption by 25%. Interpon<br />

610 Low-E requires much lower<br />

curing temperatures (170°C<br />

compared to 195°C required by<br />

the previous brand) and allows<br />

them to coat 20% more rims<br />

per box than was previously<br />

possible.<br />

<strong>Finishing</strong> – <strong>September</strong>/<strong>October</strong> <strong>2021</strong>

6 NEWS www.finishingmagazine.co.uk<br />

BCF award nominees announced<br />

Deburring Expo set for <strong>October</strong><br />

This year’s DeburringEXPO will be held from <strong>October</strong> 12 to 14 as an<br />

attendance event at the Trade Fair Center Karlsruhe in Germany.<br />

Finally, users from various industries with a wide range of tasks in the<br />

production steps of deburring and surface finishing will be able to<br />

exchange information with suppliers in face-to-face discussions again<br />

and find out about their new and further developed solutions in<br />

person. The integrated expert forum with simultaneously translated<br />

presentations (German English) also enables the crucial transfer of<br />

knowledge on current developments and trends in these<br />

manufacturing sectors.<br />

Whether it's the automotive and supplier sector, machine and<br />

equipment industry, medical device and pharmaceutical industries,<br />

measurement, precision mechanics and sensor technology, tool and<br />

mould making or energy and environmental technology - demand is<br />

booming again in many branches of industry. The component<br />

manufacturing sector, however, is facing new and changed tasks. This<br />

is due to transformation processes, different production technologies<br />

such as additive manufacturing, new and optimized materials and the<br />

trend towards the automation and digitization of production processes,<br />

as well as new regulatory requirements. As different as these may be<br />

in the various industries, burr-free and optimally-finished surfaces<br />

tailored to product specifications are playing an increasingly important<br />

role. “On the one hand, the aim is to improve quality, precision and<br />

energy efficiency in deburring and surface finishing. On the other<br />

hand, it is about reducing costs,” explains Hartmut Herdin, CEO of<br />

fairXperts GmbH & Co. KG and organizer of DeburringEXPO,<br />

describing some of the key challenges facing companies.<br />

Cutting investment<br />

Nottingham-based Sign Up Systems has invested in a Blackman &<br />

White Genesis V flatbed digital cutting system from i-Sub as it looks to<br />

speed up its finishing process, diversify its work and produce new<br />

products.<br />

The company, which started out providing aluminium systems for<br />

the signage and graphics industry, first diversified into print in 2016<br />

when it invested in a dye-sublimation machine and a 3.2m UV roll-toroll<br />

system. A few years later it installed further large format printing<br />

equipment; a move which opened up a host of potential new avenues,<br />

but also left the company needing to upgrade its finishing options.<br />

"<strong>Finishing</strong> was definitely the bottleneck in our business," explains<br />

Sign Up Systems' managing director Jon Bromhead. "We could print a<br />

lot of work; we just couldn't finish it. We realised that what we needed<br />

was that missing link - and, as it turned out, that was the Blackman &<br />

White Genesis V cutter."<br />

The British Coatings Federation (BCF) are pleased to announce the<br />

shortlisted entries for the <strong>2021</strong> Awards. Despite a difficult year for<br />

many we received a huge number of high-quality Awards entries<br />

which made shortlisting decisions really difficult. The winners will be<br />

announced at the Awards dinner on <strong>October</strong> 14th in Manchester.<br />

Sustainable Innovation Award shortlist:<br />

PPG Automotive Refinish – Moonwalk<br />

BYK-Gardner – Spectro2profiler<br />

BASF – Agilis<br />

Customer Service Award shortlist:<br />

Sun Chemical<br />

AkzoNobel – Dulux Decorator Centre<br />

Young Leader of the Year Award shortlist:<br />

Cameron Starkey, IPL<br />

Steve Coppin, U-POL<br />

Natasha Ram, PPG Architectural Coatings<br />

Natalie Hood, Jotun Paints Europe<br />

Corporate Social Responsibility Award shortlist:<br />

PPG Architectural Coatings<br />

AkzoNobel<br />

HMG<br />

Excellence in Training Award shortlist:<br />

U-POL<br />

Jotun Paints Europe<br />

Dulux Academy<br />

Marketing Campaign of the Year Award shortlist:<br />

AkzoNobel – Dulux Decorator Centre<br />

PPG – Leyland Trade Smart<br />

BASF – Glasurit<br />

Apprentice of the Year Award shortlist:<br />

Daniel Bower, Rakem Group<br />

Nathan Eckersley, HMG<br />

Josh Taylor, HMG<br />

George O-Reilly, IPL<br />

Diversity and Inclusion Award shortlist:<br />

PPG Architectural Coatings<br />

Jotun Paints Europe<br />

UL<br />

The shortlisted companies for both Coatings Care Awards, and<br />

those shortlisted for the Student of the Year Award will be<br />

announced in <strong>September</strong>.<br />

Five star safety<br />

The British Safety Council’s renowned Five Star Occupational Health<br />

and Safety Audit has been revised and updated. It now places greater<br />

emphasis on assessing how effectively an organisation manages the<br />

combined risks to workers’ health and wellbeing, as well as business<br />

resilience and recovery.<br />

The Five Star Occupational Health and Safety Audit provides a<br />

quantified outcome with detailed recommendations; it goes beyond<br />

the requirements of current health and safety management standards<br />

such as ISO 45001 and provides a structured route toward best<br />

practice status.<br />

<strong>Finishing</strong> – <strong>September</strong>/<strong>October</strong> <strong>2021</strong>

EASY OPERATION.<br />

DOUBLE PRODUCTIVITY.<br />

SuperCenter EVO<br />

Powder preparation & supply center<br />

• Ideal for frequent & fast color changes<br />

• High degree of automation for optimum efficiency<br />

• Double-designed fresh powder station for increased productivity<br />

wagner-group.com<br />

Contact<br />

Wagner Spraytech (UK) Ltd<br />

a Member of WAGNER GROUP<br />

Telephone: 01327 368410<br />

enquiries@wagner-group.com

8 NEWS www.finishingmagazine.co.uk<br />

’Introducing QUALICOAT 3.0’<br />

By Angus Mackie - QUALICOAT UK & Ireland Chair<br />

Targeted results<br />

Guyson International has recently installed a Guyson Euroblast 7PF<br />

(Pressure Fed) blast system into Merlin Archery, a leading designer and<br />

manufacturer of tournament shooting archery bows. The blast cabinet<br />

is used to deliver a uniform bead blasted cosmetic surface finish on<br />

their range of machined compound bows and to enhance the surface<br />

topography of components before anodising.<br />

After successful blast trials to meet the surface finish requirements,<br />

overseen by Ben Jones the owner of Merlin Archery, were conducted<br />

at Guyson's Skipton headquarters and manufacturing site, which has<br />

remained open and fully working throughout the pandemic, Mr Jones<br />

was happy to sign off on purchasing the new blast system.<br />

The chosen Euroblast 7PF blast system is from Guyson’s premier<br />

industrial quality range and delivers exceptional component access,<br />

with doors opening to the front, top and side, and facilitates easy<br />

loading of components into the internal blast chamber; which in this<br />

instance has the width of 1480 mm to accommodate the longest of the<br />

CNC machines aluminium compound bow parts.<br />

Merlin Archery's blast system comprises a Guyson Euroblast 7PF<br />

blast cabinet, model 75/16 Cyclone Reclamator, G27 Pressure Pot and<br />

Guyson C400 dust collection unit and delivers fast (up to four-times<br />

faster than suction fed systems), effective blast finishing on a vast array<br />

of components. Large armhole sleeve/glove assembly allows the<br />

operator greater flexibility of movement when blasting and external<br />

roof-mounted LED lighting coupled with light coloured rubber curtain<br />

lining offers additional cabinet protection and good contrast for parts<br />

visibility.<br />

SFChina on track<br />

The 34th edition of SFCHINA is<br />

on track to open its doors from<br />

November 16 to 18, <strong>2021</strong> at Hall<br />

E1 of the Shanghai New<br />

International Expo Centre<br />

(SNIEC), P.R. China. This year<br />

we have planned a total gross<br />

exhibition area of over 11,000<br />

square metres. Over 190<br />

exhibitors from 15<br />

countries/regions (as of Aug 9,<br />

<strong>2021</strong>) will showcase their new<br />

products, services and solutions<br />

in 3 exhibit zones, including<br />

‘Electroplating & <strong>Finishing</strong><br />

Technology’, ‘Environmental,<br />

Safety & Protection’ and ‘Coating<br />

Applications & Coating Products’.<br />

In addition to the physical<br />

exhibition, SFCHINA will be<br />

accompanied again with an<br />

Online Show this year, bringing<br />

exhibitors and visitors together<br />

and helping them to match<br />

businesses in a hybrid format.<br />

Although the global pandemic<br />

has somewhat constrained<br />

market growth, the finishing<br />

industry is consolidating and<br />

picking up the pace as global<br />

manufacturing industry has<br />

gradually recovered in the<br />

second half of 2020. Asia is<br />

taking the lead globally due to<br />

thriving construction and<br />

automobile industries in<br />

developing countries like India<br />

and China.<br />

In 1986 several national associations encompassing coaters of<br />

architectural parts formed a quality label organisation called<br />

QUALICOAT. The aim was to standardise procedures and increase the<br />

quality of powder coatings for its membership.<br />

As an association it is our membership who continue to work<br />

together and undertake research which enables the QUALICOAT<br />

Standard to be updated on a yearly basis. The aim of the membership<br />

continues to be to produce the highest quality coatings for extended<br />

life expectancy. With membership that includes the coaters,<br />

pretreatment suppliers and powder manufacturers QUALICOAT<br />

licences members encompasses the complete supply chain.<br />

QUALICOAT is a worldwide organisation which works to a single<br />

standard, so a specification by an architect in London for a<br />

QUALICOAT finish will be coated to the same standard in any city<br />

across the globe. Membership continues to grow and includes all of<br />

the professional architectural coaters in the UK & Ireland. To ensure<br />

standards are maintained coating members welcome unannounced<br />

inspections twice a year by an association nominated test house.<br />

Members who fail the inspection could loose their QUALICOAT<br />

licence.<br />

As with any applied finish, pretreatment is crucial to ensure that the<br />

bond of the finish is maintained, one of the crucial elements is the alloy<br />

substrate and its cleaning. In the QUALICOAT standard and the BS EN<br />

1279, the surface is to be etched with acid or alkaline to remove<br />

impurities which is followed by a pretreatment system that seals the<br />

substrate and creates the key for coating adherence. QUALICOAT 3.0<br />

goes further by looking at the alloy structure itself.<br />

With the extensive research completed by the QUALICOAT<br />

membership it is now recognised that the alloy makeup can effect the<br />

extended life expectancy of the powder coating. Enter the<br />

QUALICOAT 3.0 Label for premium corrosion resistance class.<br />

The QUALICOAT 3.0 Label allows for the use of both primary and<br />

recycled aluminium and is to be awarded to the aluminium extruder.<br />

Aluminium QUALICOAT 3.0 requires an aluminium grade 6060 or<br />

6063 where the relationship between alloying elements, extrusion<br />

quality, microstructure and corrosion potential meet the details laid<br />

down in the appendix of the latest QUALICOAT Standard. A<br />

QUALICOAT 3.0 specification will require a coating member to carry<br />

the ‘Seaside’ class membership as this is a prerequisite coating<br />

procedure for QUALICOAT 3.0.<br />

The aluminium extruder will then get the "Aluminium QUALICOAT<br />

3.0 grade" Label after a satisfactory result the following tests; an<br />

Optical Emission Spectroscopy test; an Anodic Cyclic Polarisation test<br />

and an Metallographic Study.<br />

QUALICOAT 3.0 will be driven by specifiers who are looking to<br />

achieve even higher levels of robust coatings for extended service life.<br />

Further information is available from QUALICOAT UK & Ireland.<br />

The next QUALICOAT UK & Ireland members meeting takes place<br />

on 19th <strong>October</strong> <strong>2021</strong>, at the Arden Hotel & Leisure Club, Solihull ,<br />

please contact the General Secretary, Jan Lukaszewski, via the<br />

QUALICOAT UK & Ireland website, should you wish to attend. For<br />

details on the availability of various colours and finishes contact any<br />

QUALICOAT UK & Ireland member for more information. For<br />

updated information about the use and specification of QUALICOAT<br />

in the UK and Ireland, please visit the UK & Ireland Association website<br />

at www.qualicoatuki.org<br />

<strong>Finishing</strong> – <strong>September</strong>/<strong>October</strong> <strong>2021</strong>

PosiTector ® Inspection<br />

Unrivaled probe interchangeability<br />

for all of your inspection needs.<br />

Coating Thickness Probes<br />

n Ferrous n Non-Ferrous n Combination n Ultrasonic<br />

Surface Profile Probes<br />

n Depth Micrometer n Replica Tape Reader<br />

Environmental Conditions Probes<br />

n Integral n Cabled Magnetic Probe n Anemometer Probe<br />

n 1/2” NPT n Infrared<br />

Hardness Probes<br />

n Shore n Barcol<br />

Salt Contamination Probe<br />

n Bresle Method<br />

Ultrasonic Wall Thickness Probes<br />

n Corrosion n Multiple Echo Thru-Paint n Precision<br />

n Low Frequency n Xtreme<br />

NEW<br />

Design and Features<br />

Design and Features<br />

NEW<br />

Customized Inspection Kits...<br />

Build your own kit from a selection of gauge<br />

bodies and probes to suit your needs.<br />

Coating<br />

Thickness<br />

Surface<br />

Profile<br />

Environmental<br />

Conditions<br />

Hardness<br />

Salt<br />

Contamination<br />

Ultrasonic<br />

Wall Thickness<br />

Backwards Compatibility! The redesigned PosiTector gauge body accepts ALL coating thickness<br />

(6000/200), environmental (DPM), surface profile (SPG/RTR), salt contamination (SST), hardness<br />

(SHD/BHI), and ultrasonic wall thickness (UTG) probes manufactured since 2012.<br />

DFT DFT Instruments UK UK LTD LTD<br />

16A 16A Long Long Drive, Meadway, Berkhamsted, Herts HP4 HP4 2PN 2PN<br />

t: t: 01442 879494 f: f: 01442 879595<br />

www.dftinstruments.co.uk e: e: sales@dftinstruments.co.uk<br />

Proud supplier of of DeFelsko Inspection Instruments

10 CASTING<br />

Casting off<br />

Various crucible melting methods are<br />

used up to date for metal melting in<br />

investment casting. Although widely<br />

used, they have some disadvantages. For most<br />

(non-reactive) materials ceramic crucibles are<br />

used which can result in impurities or ceramic<br />

inclusions affecting the quality of the cast part.<br />

Reactive metals, e.g. Titanium alloys, are<br />

melted in cold wall crucibles. The low<br />

superheat and high power consumption in the<br />

cold wall sealing process is a price for a<br />

cleaner melting process. For the first time,<br />

non-contact levitation melting can be used as<br />

an alternative on an industrial scale, as ALD<br />

Vacuum Technologies GmbH has succeeded<br />

in increasing the previous limited weight<br />

quantity of only 50g to unprecedented 500g.<br />

Using numerical modelling the melting<br />

experts have devised a new system design<br />

that works with two alternating magnetic<br />

fields, which allows these higher weight<br />

quantities to be kept in levitation. Now with<br />

FastCast various metals and alloys like<br />

titanium, aluminum, or super alloys can be<br />

melted reliable in a non-contact levitation<br />

process without contamination and<br />

subsequently casted in a mold. The process<br />

allows a gentle, less turbulent filling process of<br />

the mold, which is favored by a high-speed<br />

take-off of the mold and therefore the low<br />

relative velocity between free-falling melt and<br />

sinking mold. The special and extensively<br />

patented design allows strong superheating<br />

with comparatively low power input which<br />

favors “defect”-free casting resulting in<br />

economic benefits and lower mould<br />

preheating temperatures. The integrated mold<br />

centrifuge coupled with the high superheat<br />

enables the casting of highly complex and<br />

filigree investment castings made of reactive<br />

titanium alloys.<br />

Ceramic crucibles are widely used for<br />

casting nickel-based or iron-based alloys. They<br />

are cost-efficient and to a certain extent allow<br />

superheating, i.e. raising the temperature<br />

above the liquidus temperature of the alloy.<br />

<strong>Finishing</strong> - <strong>September</strong>/<strong>October</strong> <strong>2021</strong><br />

continues on page 12

12 CASTING<br />

However, these crucibles are rather unsuitable<br />

for melting extremely reactive materials at<br />

high temperatures, as this leads to an<br />

inadmissible contamination of the melt. This<br />

prevents the manufacturing of high purity,<br />

near net-shape casting parts made of metals<br />

and alloys such as titanium. By comparison,<br />

the competitive cold wall casting technique is<br />

more suitable for such materials but requires<br />

high amount of power for melting the material<br />

in water-cooled copper crucibles. Furthermore,<br />

overheating is not very feasible with this<br />

method, because most of the power required<br />

for this flows directly into the cooling water of<br />

the crucible and is, so to speak, dissipated.<br />

Therefore, a melting process without the<br />

material coming into contact with the crucible<br />

(non-contact) would be desirable. The ALD<br />

Vacuum Technologies GmbH had set itself the<br />

goal of converting this principle into a fully<br />

functional plant fit for industrial use.<br />

“One process fairly suitable to start with was<br />

the so-called levitation melting,” reports Dr.<br />

Sergejs Spitans, R&D Process Engineer,<br />

Physicist & Simulation Expert at ALD Vacuum<br />

Technologies. “A ‘conventional’ levitation<br />

melting uses an axisymmetric coil to create a<br />

magnetic field in which metallic samples can<br />

be contact-free confined and melted. The<br />

problem is that Lorentz force confinement<br />

vanishes on the symmetry axis and the melt<br />

leakage is prevented in this lowest point of a<br />

levitated melt only by the surface tension.<br />

Therefore, only small molten metal samples up<br />

to 50 g can be levitated in this ‘conventional’<br />

way.” As part of his dissertation work and<br />

under the supervision of Prof. Dr.-Ing. (Doctor<br />

of Engineering) Egbert Baake from the<br />

Institute of Electrotechnology (ETP) at Leibniz<br />

University Hannover, Dr. Sergejs Spitans from<br />

ALD used numerical models and various<br />

experiments to find a way to significantly<br />

increase the melt weight. Together with<br />

engineers from ALD, a pilot plant was<br />

developed where numerous aluminum-,<br />

nickel- and titanium- (Ti-6Al-4V) alloys up to<br />

500 g were successfully melted in high purity<br />

without inclusions. The method applies two<br />

horizontal and orthogonal electromagnetic<br />

fields of different frequencies in order to exert<br />

a Lorentz force also at the bottom of the<br />

levitated sample. Therefore, the weight of the<br />

charge can be increased and the charge can<br />

be melted drip- and leakage-free. Levitation<br />

melting prevents contamination of the molten<br />

metal with the crucible material and results in<br />

significantly higher alloy purity. In addition,<br />

heat losses from the liquid metal are limited to<br />

radiation and evaporation only, which allows<br />

much higher superheat temperatures to be<br />

achieved. The high superheat opens up new<br />

avenues for mold design and thus for thinwalled<br />

and complex castings such as medical<br />

or aerospace applications.<br />

From concept work to<br />

industrial-scale pilot plant<br />

After an extensive series of simulation-aided<br />

design iterations, the optimized process was<br />

transferred into a functional plant including<br />

feeder, preheating furnace and casing. “The<br />

final scale-up configuration has a modular<br />

levitation assembly group that consists of four<br />

ferrite poles and four inductors, each is watercooled<br />

and protected by heat shields,”<br />

describes Spitans. “The opposing inductors<br />

form a pair that operates at the same<br />

frequency and produces an instantaneous<br />

magnetic field in the same direction. The<br />

orthogonal orientation allows to compensate<br />

the regions of the zero Lorentz force that<br />

occurs if only one field is activated.” “Levitation<br />

melting is only slightly more efficient than the<br />

cold wall crucible, however, the advantages<br />

like predefined melt purity, absence of the<br />

skull scrap, fast melting speed and<br />

tremendous superheat up to 250 C at the<br />

moment of mold filling makes the process<br />

extremely attractive for complex castings,”<br />

Spitans adds.<br />

To meet the demands of industrial<br />

production, the pilot plant offers a semiautomated<br />

process chain with up to 10 molds.<br />

The upper housing contains a vertical feeding<br />

unit of the pre-alloyed metal electrode to be<br />

melted. The lift moves the mold to the upper<br />

position right below the melting zone. The<br />

melting starts as the lower end of the vertically<br />

oriented Ti-alloy electrode is immersed in the<br />

region of two-frequency horizontal and<br />

orthogonal electromagnetic (EM) fields. EM<br />

fields rapidly melt up to 500 g of material<br />

from the tip of the electrode and<br />

simultaneously confine the liquid metal in a<br />

levitation condition. The electrode is moved up<br />

and detached, the levitated melt can be<br />

superheated. After that the melt is released by<br />

retracting poles and it falls down under gravity<br />

in the awaiting preheated mold. Instantly the<br />

mold is accelerated vertically down to reduce<br />

the relative velocity and to catch the melt<br />

without splashing. Further mold deceleration<br />

to a full stop and consequent spinning<br />

completes the smooth and qualitative mold<br />

filling. After that, the form exits through the<br />

unloading chamber and the next cycle can<br />

start. All in all, the cycle times are rather short,<br />

with less than 60 seconds, making the process<br />

very economical.<br />

Plant can be used for test runs by<br />

interested companies<br />

Up to this point, almost all relevant titaniumand<br />

aluminum-based alloys as well as super<br />

alloys were cast successfully using the pilot<br />

plant. To ensure the suitability and efficiency of<br />

the system, common investment casting<br />

components such as turbocharger wheels<br />

were cast using the plant. Based on this<br />

design, ALD is going to develop a production<br />

FastCast system in cooperation with interested<br />

users, specifically for the needs of their own<br />

production. Feeding and mold number<br />

(adapted to the mold shell) in particular will be<br />

taken into account. Therefore, the<br />

demonstrator can be used for test runs.<br />

Although the actual plant is semi-automated, a<br />

special department at ALD is working on more<br />

features that meet the requirements of<br />

Industry 4.0. For example, a digital twin of<br />

each casting part can be generated to ensure<br />

highest quality control. Since they are<br />

individual casts, each part can be tracked<br />

down to defects that may show up before or<br />

after the casting. “The high purity, excellent<br />

reproducibility, and continuous and automated<br />

single batch production line favors a very high<br />

casting quality, making non-contact levitation<br />

melting particularly suitable for investment<br />

casting parts in demanding sectors such as<br />

aerospace and medical technology. We can’t<br />

wait to move this process to the next level<br />

together with industry partners,” Spitans sums<br />

up.<br />

In the next issue:<br />

Robotics<br />

Anti Corrosive <strong>Finishing</strong><br />

Advanced Surface<br />

Technology<br />

Precious Metal <strong>Finishing</strong><br />

<strong>Finishing</strong> - <strong>September</strong>/<strong>October</strong> <strong>2021</strong>

OUR SOLUTIONS<br />

OUR SOLUTIONS<br />

FOR 2K MIXING IN<br />

WOOD FINISHING.<br />

TwinControl<br />

2K mixing system with AirCoat technology<br />

• Reliable results<br />

• Easy handling<br />

• High precision & mixing accuracy<br />

wagner-group.com<br />

Contact<br />

Wagner Spraytech (UK) Ltd<br />

a Member of WAGNER GROUP<br />

Telephone: 01327 368410<br />

enquiries@wagner-group.com

14 NADCAP<br />

Passes with flying colours<br />

The Wallwork heat treatment facility in<br />

Manchester, UK, has again passed its<br />

Nadcap audit with Merit, making it the<br />

largest scope for a single site in the UK,<br />

covering nine check sheets. This creates a<br />

one-stop aerospace heat treatment facility.<br />

Nadcap accreditation is the highest level of<br />

international aerospace approval and is vital<br />

to doing business in this high-value sector of<br />

the economy.<br />

"At over 95,000 square feet, this is the<br />

largest single-site heat treating facility in the<br />

UK with this level of aerospace scope. From<br />

a wide range of available treatments, we<br />

provide aerospace engineers with a one-stopshop,<br />

backed by extensive laboratory, quality<br />

testing and technical expertise. We work with<br />

them to create specific processes that meet<br />

their exact requirements and unique needs,"<br />

explains Wallwork director, Simeon Collins.<br />

As a key supplier of metal heat treatment<br />

processes to aerospace engineering primes<br />

such as Airbus, BAE systems and Rolls Royce,<br />

many commercial and defence aircraft are<br />

flying today with components that have been<br />

heat treated by Wallwork. From complex jet<br />

engine and landing gear parts, to fasteners<br />

and fixings, the company provides the same<br />

attention to detail, quality and customer<br />

service across all its sites based on the high<br />

standards of its aerospace approvals.<br />

Aerospace components sometimes require<br />

the design and casting of special jigging and<br />

furnace fixings. These optimise efficiency and<br />

best value for the customer and provide a<br />

platform for component stabilisation. To<br />

ensure bespoke castings are made on fast<br />

turnarounds to match customer<br />

requirements, the company has its own onsite<br />

foundry equipped with CAD/CAM<br />

pattern making machines dedicated to this<br />

process.<br />

"Safety and traceability are vital to<br />

aerospace, and retaining Nadcap<br />

accreditation gives our customers confidence<br />

that we have the quality processes in place to<br />

partner with them. Our quality team and<br />

staff work hard, and have been doing so<br />

since our initial involvement with Nadcap in<br />

2006, to ensure that we maintain these high<br />

standards," added Simeon.<br />

As always, the company's dedicated<br />

commercial vehicle fleet is poised for speedy<br />

pick-up and delivery of orders anywhere in<br />

the UK – adding to the complete service the<br />

company provides to the aerospace industry.<br />

<strong>Finishing</strong> - <strong>September</strong>/<strong>October</strong> <strong>2021</strong>

Go for performance.<br />

Leave<br />

the dust<br />

behind.<br />

NEW! 3M Xtract Cubitron II Net Disc 710W<br />

The new 3M Xtract Net Disc eliminates<br />

the trade-off between dust extraction<br />

and disc performance, improving<br />

productivity and offering a virtually<br />

dust-free sanding process.<br />

• Up to 97% dust extraction for a<br />

virtually dust-free work environment<br />

• Featuring the exclusive 3M<br />

Precision-Shaped Grain technology<br />

• Designed for the metalworking<br />

industry to help you deliver excellent<br />

finish each time<br />

• Available in grades ranging from<br />

80+ to 320+<br />

The ultimate sanding system<br />

Visit our<br />

website to<br />

discover more.<br />

Scan me:<br />

© 3M <strong>2021</strong>. All rights reserved. 3M, Cubitron, and 3M Xtract, and the unique hole pattern are trademarks of 3M Company. OMG211238

16 POLISHING<br />

Perfect polish<br />

ABlack Country manufacturer that puts<br />

the finish on boutique hotels, nuclear<br />

reactors and life-saving medical<br />

equipment has just completed its latest<br />

investment drive.<br />

Professional Polishing Services (PPS), which has<br />

increased its workforce by 25% since lockdown<br />

eased, has just installed a new dull polishing line<br />

to help it boost capacity and achieve its target of<br />

£2m sales by the end of 2022.<br />

The company has spent over £250,000 on<br />

the latest purchase and this gives it the<br />

capability to apply a variety of finishes, such as<br />

dull polish and satin finish, onto stainless steel,<br />

aluminium, brass and copper sheet.<br />

It comes just two years after it took<br />

ownership of new extraction equipment, pick<br />

and place systems and two Autopilot PHA<br />

bright polishers with automated handling,<br />

acquisitions that were only operational for six<br />

months before Covid-19 struck.<br />

“Anyone in the world can touch up to 30<br />

things we have polished every day - not bad<br />

for a small manufacturer based in West<br />

Bromwich is it?” explained Kirsty Davies-<br />

Chinnock, managing director of PPS.<br />

“Like many firms, we’ve had to withstand<br />

some tough times over the last eighteen<br />

months, but the recovery is now back on and<br />

we’re trying to put in place the technology we<br />

need to meet escalating demand from pretty<br />

much every sector, including automotive,<br />

construction, food and drink, nuclear and<br />

leisure.<br />

“In the early days of the lockdown, we<br />

furloughed everyone except two senior<br />

managers and myself, who moved to the<br />

shopfloor to ensure work for the medical<br />

sector was completed. Before long we had to<br />

call staff back, as we were polishing steel that<br />

was going into ventilator stands and the big<br />

vats that were helping to develop the<br />

vaccines.”<br />

She went on to add: “More than £750,000<br />

has been invested in reinforcing our position<br />

as a market leader in the last three years and<br />

we are confident this will play a key role in us<br />

achieving record performance over the next<br />

twelve months.”<br />

Professional Polishing Services offer a<br />

bespoke stainless steel and non-ferrous<br />

polishing service to a client base that spans<br />

the world, with its efforts seen as far afield as<br />

Hong Kong and Australia.<br />

The company’s reputation for quality - all<br />

processes are governed by ISO 9001:2015 -<br />

and its commitment to fast lead times has<br />

seen it grow sales by £500,000 in the last<br />

twelve months, taking it to £1.7m by the<br />

financial year-end.<br />

Its strategy focuses on combining<br />

investment in the best equipment and the<br />

best people with a desire to tap into the<br />

knowledge of local Universities, already taking<br />

on two interns from WMG to improve<br />

manufacturing efficiencies and process flow.<br />

Kirsty continued: “There are plenty of<br />

challenges in manufacturing, but I think we<br />

are all really pleased with how the economy<br />

appears to be bouncing back and we want to<br />

make sure we play our role in the recovery.<br />

“The latest investment will give us capacity<br />

to take on new work and deliver faster lead<br />

times, yet it isn’t the end of our spending. I’ve<br />

already got my eye on another two machines,<br />

which would be UK firsts for the polishing<br />

sector.”<br />

<strong>Finishing</strong> - <strong>September</strong>/<strong>October</strong> <strong>2021</strong>

The Choice for the Professional Powder Coater<br />

Gema UK<br />

01202 763942<br />

uk.sales@gema.eu.com

18 PRE-TREATMENT<br />

Aluminium surface treatment<br />

with innovative technologies<br />

The Surface Treatment global business<br />

unit of BASF's Coatings division,<br />

operating under the Chemetall brand,<br />

which provides technologies with a sustainable<br />

focus to optimize pre-treatment and anodising<br />

processes with a complete product portfolio<br />

for all types of aluminium finishing<br />

applications.<br />

Aluminium is one of the most commonly<br />

used metals worldwide for many different<br />

applications and industries. The requirements<br />

for excellent paint adhesion and long-term<br />

corrosion resistance are long established for<br />

the pre-treatment of aluminium alloys.<br />

Excellent long-lasting adhesion and corrosion<br />

performance are achieved with Chemetall’s<br />

GSB, Qualicoat and Qualanod approved<br />

products and customised processes.<br />

Chemetall offers a one stop supply package<br />

providing the following:<br />

• cutting fluids and coolants used in<br />

extrusion and die shops<br />

• cleaners, etches/pickles, conversion<br />

coatings and additives used in pre-treatment<br />

process<br />

• cleaners, decorative etches, brighteners,<br />

desmuts, anodising, colouring and sealing<br />

systems used in anodising process<br />

• waste water treatment products<br />

• paint strippers<br />

• extrusion die cleaning products<br />

• Laboratory analysis one-off/contract basis.<br />

Gardobond X products and Oxsilan<br />

products meet the most demanding quality<br />

requirements and combine eco-friendly<br />

properties i.e. chrome free and heavy metals<br />

free to multi metal applications and are now<br />

widely used via all types of process<br />

applications in the aluminium finishing<br />

industry as the alternative to hexavalent<br />

chromium.<br />

Anodising aluminium offers an aesthetic<br />

finish and long-lasting corrosion protection.<br />

Chemetall’s anodising product range including<br />

Gardo cleaners, additives for alkaline etching,<br />

Gardacid desmut and the Gardo® Seal series<br />

for sealing processes help the customer in<br />

optimising the anodising process, maximising<br />

efficiencies, and producing high quality in the<br />

form of appearance and function.<br />

Anodising finishes add creativity and<br />

vibrancy into the construction industry,<br />

bringing an element of uniqueness.<br />

Examples of Chemetall s portfolio for<br />

aluminium pre-treatment and anodising,<br />

meeting all requirements of GSB, Qualicoat<br />

and Qualanod specifications:<br />

• Gardoclean – silicate free, borate-free and<br />

phosphate-free cleaners and alkali etching<br />

series.<br />

• Gardacid – acid etches, free of HF with<br />

special additives to avoid plant material attack,<br />

reducing sludge build up, leading to lower<br />

maintenance cost and extended bath solution<br />

lifetime.<br />

• Gardobond X Cr free series Nitrogen free<br />

and Oxsilan thin film technologies for the<br />

conversion stage, all Qualicoat and GSB<br />

approved.<br />

<strong>Finishing</strong> - <strong>September</strong>/<strong>October</strong> <strong>2021</strong>

PRE-TREATMENT 19<br />

technology supplier to the Aluminium<br />

<strong>Finishing</strong> industry. We are proud of our<br />

association with leading companies,<br />

organisations and associations around the<br />

world.<br />

Chemetall customers can choose between<br />

different, customised, eco-friendly and reliable<br />

solutions for our modern-life challenges to<br />

achieve surface treatment processes which are<br />

high performing, safe and environmentally<br />

sound. We are committed to a sustainable<br />

future through new products, processes and<br />

technologies as well as contribute to<br />

sustainability with our passion for chemistry,<br />

people and the planet.<br />

Close working relationships with<br />

facility/equipment providers – ensuring value<br />

focused projects – optimizing processes and<br />

products.<br />

• Gardobond Additive H 7526 – for use in<br />

the anodising stage, providing shorter process<br />

time, quality enhancement, extended bath life,<br />

energy savings and increased productivity.<br />

• Gardo Seal 1999 – Qualanod approved<br />

additive for the sealing of anodised surfaces<br />

which enables a vital reduction in operational<br />

actongate - address alts.qxp_Layout 1 09/11/2016 08:51 Page 1<br />

temperatures and process times as well as<br />

energy savings and increased productivity.<br />

• Gardobox – customised service package.<br />

Chemetall offers key local support with<br />

decades of experience in surface treatment of<br />

metal substrates. Chemetall is recognised as<br />

an environmentally sound and game changing<br />

In the next issue:<br />

Robotics<br />

Anti Corrosive <strong>Finishing</strong><br />

Advanced Surface<br />

Technology<br />

Precious Metal <strong>Finishing</strong><br />

Acton Gate Systems Limited - Tel: 01902 249299<br />

Hilton Hall Business Centre, Hilton Lane, Essington, Staffordshire, WV11 2BQ<br />

web: www.actongate.co.uk - email: enquiries@actongate.co.uk<br />

<strong>Finishing</strong> - <strong>September</strong>/<strong>October</strong> <strong>2021</strong>

20 INSTALLATIONS<br />

Colour match<br />

New filters launched<br />

Hendor has launched its new filters for the surface finishing industry.<br />

After years of research and testing, a completely new and significantly<br />

improved design has been created. With this, we take a pioneering<br />

step in manufacturing high quality filtration systems.<br />

With the advent of new technologies and the search for optimum<br />

efficiency, the company has developed a new, innovative design under<br />

the leadership of its technical director Hessel Bohncke.<br />

The new Hendor filters are even more user-friendly and efficient.<br />

Completely new are the double-welded bases that ensure less pressure<br />

loss, more flow, more reach and more energy efficiency of the filter.<br />

Absolutely no concessions have been made on the quality of raw<br />

materials, features or service-friendliness. The new filters consist of<br />

fewer components, but are of course realized at the same high quality.<br />

The filters will be offered in three series and will thus replace the<br />

current variant. All available with filter plates or candles, in combination<br />

with a magnetic drive or mechanical seal pump. These include the<br />

series 3, 7 and 15. And that is just the beginning. More series and<br />

products will follow in the future.<br />

Aerospace alternatives<br />

Indestructible Paint Ltd.’s commitment to developing alternatives to<br />

chrome-based products has been enhanced through a further focus on<br />

the aerospace industry by the performance paint and coatings<br />

manufacturer. The company is set to continue its commitment to this<br />

key field of corrosion protection for light alloys – one of the most<br />

challenging application areas – as a result of new chrome replacement<br />

target dates that have now been set for specific products by the<br />

European Chemical Agency (ECHA).<br />

“REACH authorisation for specific products that use pentazinc<br />

chromate octahydroxide has been granted for 12 years to January<br />

2031,” says Brian Norton, Indestructible Paint’s managing director, at<br />

the company’s Birmingham office. “This relates to supplies of a<br />

particular anti-corrosion primer that is used by our aerospace customers<br />

on components that relate only to flight operations such as engine fan<br />

cases and fuel tanks.” He points out that time is now available for<br />

thorough certification of the latest generation of Indestructible Chrome<br />

Free Coatings that meet the demands of these harsh environments.<br />

“However, the overall company strategy, which has been a key focus<br />

of Indestructible Paint’s highly regarded research and development<br />

department for a number of years, is to continue development of<br />

products that can replace those that include chrome pigments,” adds<br />

Brian Norton. In Indestructible Paint’s case, this has pointed towards<br />

developing specific anti-corrosion primers that are particularly relevant<br />

to one of the world’s leading aerospace manufacturing companies.<br />

“The agreement to extend the use of this particular primer beyond<br />

the sunset date for pentazinc chromate octahydroxide recognises the<br />

importance and complexity of the subject – which, of course, has an<br />

important health and safety significance,” continues Brian Norton.<br />

Datacolor has launched its latest<br />

color tool, the RAL<br />

COLORREADER for<br />

professionals and consumers.<br />

Combining the renowned color<br />

legacy of RAL with the color<br />

management expertise of<br />

Datacolor, the RAL<br />

COLORREADER lets you scan<br />

the flat surface of any color to<br />

instantly find its precise RAL<br />

color match via its feature-rich<br />

companion app. In addition to<br />

providing accurate color matches,<br />

users can tap on their color<br />

match to find coordinating<br />

colors, conveniently organized<br />

into monochromatic, analogous,<br />

triad and complementary color<br />

Artistic effect<br />

palettes, simplifying and<br />

facilitating the color matching<br />

and coordinating processes.<br />

For the professional, the RAL<br />

COLORREADER streamlines the<br />

workflow process, allowing<br />

architects, interior designers, and<br />

painters the ease and ability to<br />

accurately match paint colors<br />

right from the job site without<br />

having to remove wall samples<br />

and take them to the paint store.<br />

RAL COLORREADER also<br />

provides precise color data (CIE<br />

Lab, RGB, Hex, CMYK, LCH and<br />

LRV) for digital design work,<br />

allowing users to easily convert<br />

color matches to other palettes if<br />

needed.<br />

The team at Hull-based Humber Galvanizing Ltd has helped protect<br />

the long-term future of an iconic sculpture created to mark the 50th<br />

anniversary of a local mineral mine.<br />

Boulby Mine, situated near Staithes, North Yorkshire, is the UK’s<br />

deepest working mine and was the first in the world to undertake the<br />

commercial production of polyhalite – a rare mineral commonly used<br />

as fertiliser. To mark its half a century, owners of the mine (ICL<br />

Boulby), commissioned artist Katie Ventress to produce a<br />

commemorative bench to showcase life underground.<br />

A replica of the ‘Bait Tables’ that are located at the bottom of the<br />

mine and where the miners sit to have lunch and conduct meetings,<br />

the artwork comes complete with a ‘communications board’ featuring<br />

tannoy, phone, and light plus a full-size figure of a modern-day miner.<br />

The table-top itself is produced from a sheet of laser cut stainless-steel<br />

incorporating information about the mine, as well as detailed map of<br />

the underground tunnels.<br />

The elaborate picnic-style bench took just over three months to<br />

produce, after which it was sent to the team at Humber Galvanizing,<br />

part of Wedge Group Galvanizing Ltd, for processing. After being<br />

galvanized to protect it from the outside elements, the artist then used<br />

acid etching to create striking highlight effects.<br />

<strong>Finishing</strong> – <strong>September</strong>/<strong>October</strong> <strong>2021</strong>

PYROLYSIS &<br />

BURN OFF OVENS<br />

UK’S LEADING MANUFACTURER<br />

Our Pyrolysis ovens provide you with a quick and highly effective<br />

process for the removal of plastic, paints and resins<br />

Longworth’s pyrolysis & burn off ovens are second to none in design and build quality, built to last and have the latest<br />

in technological features. Our ovens provide a quick and highly effective process for the removal of plastics, paints<br />

and resins from jigs, filters, shelving, food trays, motors, automotive parts and a multitude of other components.<br />

Accreditations<br />

BS EN ISO 9001:2008<br />

Call Longworth today for a no obligation meeting on how we can help you and your business<br />

call<br />

01254 680501<br />

email<br />

enquiries@bmlongworth.com<br />

visit<br />

www.bmlongworth.com

22 CASE STUDY<br />

The latest ‘big win’<br />

The commissioning of a new MecWash<br />

MWX400 has led to “big wins” for the<br />

quality team at Croom Precision Medical,<br />

the Co. Limerick based manufacturer of<br />

medical implants and instruments.<br />

Set up in 1984, the company is a FDAregistered<br />

contract manufacturer of<br />

orthopaedic implants, specialising in designing<br />

and manufacturing components for the<br />

medical device industry, and machining and<br />

handling precious metals for use in a sterile<br />

environment. Croom Precision Medical<br />

supplies precision components and high value<br />

consultancy services for medical applications,<br />

like orthopaedics, trauma and extremities,<br />

cardiovascular and vascular.<br />

Croom Precision Medical, located in county<br />

Limerick, Ireland, has invested €8.6 million<br />

into its new production facilities,<br />

manufacturing Class I, II and III medical<br />

implants and instruments. Part of the<br />

investment went into a MecWash MWX400<br />

to support the exacting cleanliness standards<br />

required of medical equipment, increasing<br />

decontamination levels, according to Patrick<br />

Byrnes, chief executive officer of Croom<br />

Precision Medical.<br />

“In the manufacture of Class II and III<br />

medical implants here at Croom Precision<br />

Medical, we must raise the bar on<br />

qualification criteria to ensure that every<br />

implant is prepared for sterility. After all,<br />

everything we produce here ends up in a<br />

human body somewhere around the world,”<br />

Byrnes said.<br />

“The MecWash system is utilised in our<br />

validated production process. The system has<br />

undergone full qualifications in installation,<br />

operation and process. These conditions test<br />

the process under ‘worst case cleaning<br />

conditions’ according to a set of parameters<br />

defined by our quality team.<br />

“It’s imperative that our products for the<br />

medical industry are cleaned with the<br />

sophistication required. Everything in the<br />

machining process, all oils, contaminants,<br />

swarf, tissue papers; all of these elements<br />

must be removed in the cleaning process as<br />

the standards for medical equipment are so<br />

stringent,” he adds.<br />

Patrick said: “Previously we used a series of<br />

single modular ultrasonic baths. We were<br />

limited by volume, pressure and power. The<br />

MecWash machine meets all of our<br />

requirements and more by giving a<br />

controlled, validated outcome on each<br />

processing cycle. This was a big win for our<br />

quality team where operator interference was<br />

completely removed. In addition, the system’s<br />

cycle time is a great deal faster, enabling our<br />

operations team to get more production<br />

through on a shift basis. It’s a big win.”<br />

Croom Precision’s investment also brings<br />

new advanced grinding machinery, CNC,<br />

finishing and metal inspection machinery to a<br />

factory floor being expanded by 30,000ft2.<br />

Patrick Byrnes, chief executive officer of<br />

Croom Precision, said: “In order to position<br />

ourselves for continued success on the global<br />

stage and attract new customers from the<br />

North American and European markets, we’ve<br />

made the necessary investments into new<br />

equipment for our manufacturing facility.”<br />

John Pattison, managing director of<br />

MecWash, said: “This application of the<br />

MWX400 is further proof of our credentials<br />

within the healthcare industry. We have a<br />

proud history of providing the immaculate<br />

cleaning standards required by the medical<br />

and precision engineering industries.”<br />

<strong>Finishing</strong> - <strong>September</strong>/<strong>October</strong> <strong>2021</strong>

FNG Advert July<strong>2021</strong>.pdf 1 01/07/<strong>2021</strong> 13:29:34<br />

Industrial Ultrasonic Cleaners<br />

Effective cleaning results for all manufacturing,<br />

processing and maintenance applications.<br />

32 - 155 Litre<br />

Capacity*<br />

Quickly and effectively<br />

remove contaminants<br />

from crevices and other<br />

hard to reach areas.<br />

C<br />

M<br />

Y<br />

CM<br />

MY<br />

CY<br />

The innovative integrated<br />

filtration and recirculation<br />

system of both the Neon and<br />

Argon Series minimises fluid<br />

contamination after cleaning,<br />

reducing running costs and<br />

improving component<br />

cleanliness.<br />

MY<br />

K<br />

35 -125 Litre<br />

Capacity<br />

The Neon Series offers multi-stage compatibility<br />

to incorporate wash, rinse and dry.<br />

The Argon Series delivers outstanding cleaning performance<br />

with cost saving and environmental benefits for processing<br />

large components or multiple batches.<br />

COMPLETE RANGE OF INDUSTRIAL COATINGS<br />

• Waterborne • Solventborne • High Solid<br />

• Powder • E-Coat<br />

SERVING A RANGE OF MARKETS<br />

• General Finishes • Heavy Equipment • Design<br />

• Architectural • Transportation • Energy • Rail<br />

• Furniture • Electronics • Military<br />

250 -1000<br />

Litre<br />

Capacity*<br />

Inver® and Syntha Pulvin®<br />

are brands of<br />

The Sherwin-Williams Company<br />

*Other sizes available, contact us on:<br />

sales@ultrawave.co.uk +44 (0)2920 837337<br />

www.ultrawave.co.uk<br />

CONTACT<br />

The Sherwin-Williams Company, Goodlass Road, Speke,<br />

Liverpool, L24 9HJ, United Kingdom<br />

T: +44 (0)151 486 0486 | liverpool.sales@sherwin.com<br />

oem.sherwin-williams.com | www.synthapulvin.co.uk

24 CASE STUDY<br />

Peak performance<br />

The performance paint and coatings<br />

expertise that has long seen<br />

Indestructible Paint Ltd. play an<br />

important role in commercial and military<br />

aerospace has now extended into one of the<br />

most celebrated sectors of the industry. The<br />

Birmingham-based company has developed<br />

coating solutions for a series of propeller<br />

blades that have been fabricated for the<br />

famous Spitfire – meeting specific challenges<br />

associated with the wooden material used.<br />

Hercules Propellers, who have a leading<br />

reputation for the production of propeller<br />

blades for the leisure aircraft sector, have<br />

been commissioned to manufacture propellers<br />

as part of a Spitfire restoration programme<br />

being undertaken by the Biggin Hill Heritage<br />

Hangar. The need to ensure each blade is<br />

fully protected from the rigors of operation<br />

and the elements has prompted the<br />

organisation to make the most of<br />

Indestructible Paint’s expertise.<br />

John Bourke, technical sales manager at<br />

Indestructible Paint, emphasises key<br />

considerations that have had to be<br />

accommodated –<br />

“Spitfire propellers are manufactured from<br />

hydro lignum – an extremely dense wood<br />

substrate that requires the protective coating<br />

to bond and perform to the highest standard,”<br />

he says. “We have therefore worked with<br />

Hercules Propellers to design a coating system<br />

that comprises a two-pack epoxy base coat,<br />

two-component erosion coating, yellow<br />

tipping paint and a clear semi-matt<br />

polyurethane lacquer.“<br />

The coatings were applied following the<br />

shaping of the propellers from timber in a<br />

dedicated machining centre installed by<br />

Hercules Propellers at its premises in Stroud.<br />

Trials were completed on a non-flight<br />

prototype to prove the system before the first<br />

set of four propellers for flight was completed.<br />

“There can be few aircraft that are better<br />

recognised or more iconic than the legendary<br />

Spitfire which has a history that will be<br />

acknowledged by millions of people in this<br />

country and much further afield,” adds Brian<br />

Norton, Indestructible Paint’s managing<br />

director. “We have extensive experience in<br />

developing coatings that are used in<br />

aerospace manufacturing and maintenance<br />

worldwide so are delighted to apply this<br />

knowledge to a dedicated and significant part<br />

of the industry.<br />

“Rupert Wasey, managing director at<br />

Hercules Propellers, and his team deserve<br />

huge credit for the work they do in helping to<br />

keep memories alive – with a little help from<br />

the most advanced and modern coatings<br />

technology available.”<br />

<strong>Finishing</strong> - <strong>September</strong>/<strong>October</strong> <strong>2021</strong>

26 SPRAY GUN<br />

Getting a top finish<br />

In addition to the automatic model<br />

TOPFINISH GA 1020/1030, the product<br />

family of WAGNER airspray guns also<br />

includes the manual gun TOPFINISH GM<br />

1030P with paint connection. The new<br />

TOPFINISH GM 1030G with gravity cup can<br />

also be used for a wide range of applications<br />

in a wide variety of industrial sectors, such as<br />

the wood, metal or plastics industries.<br />

Flexible application possibilities<br />

For flexible processing of low- to highviscosity<br />

materials with a high solids content,<br />

the GM 1030G, just like the GM 1030P, has<br />

a nozzle with a maximum material passage of<br />

9 mm. All components in contact with the<br />

material are made of durable stainless steel.<br />

Solvent-resistant seals allow uncomplicated<br />

use of the gun with both water- and solventbased<br />

materials. Depending on the<br />

application, a wide range of proven air caps,<br />

nozzle sizes and other accessory components<br />

can be used, each of which is also compatible<br />

with the GA 1020/1030 and GM 1030P<br />

models. The different hard plastic cups can be<br />

used several times.<br />

Proven technology for efficient<br />

results<br />

Just like the GM 1030P, the new gravity<br />

cup variant also produces an extremely<br />

uniform spray pattern thanks to various<br />

functions. The optimized air channel ensures<br />

very low paint mist and saves material<br />

consumption. For process-reliable coating with<br />

a consistent material flow rate, the GM 1030G<br />

is equipped with a fixable needle stroke<br />

adjustment. "This additionally optimizes<br />

material use. Overall, an application efficiency<br />

of up to 88% can be achieved during<br />

coating," reports Peter Neu, senior product<br />

manager at WAGNER. The large material and<br />

air passages of the components also support<br />

perfect atomization and at the same time<br />

allow very fast working.<br />

Durable components & easy<br />

operation<br />

As with all other WAGNER guns, great<br />

importance has been attached to a long<br />

service life and easy handling of the GM<br />

1030G. Thanks to the two-part nozzle,<br />

consisting of nozzle head and nozzle nut, it is<br />

sufficient to replace only the nozzle head<br />

when necessary instead of replacing the<br />