Food & Beverage Asia October/November 2022

Food & Beverage Asia (FBA) is the leading source of food and beverage news in Asia since 2002. FBA delivers a comprehensive view of the food and beverage landscape, spanning across the latest health and nutrition trends and industry innovations in ingredients, recipe formulations, food science, sustainability, packaging, and automation, as well as advancements in agri and food-tech.

Food & Beverage Asia (FBA) is the leading source of food and beverage news in Asia since 2002. FBA delivers a comprehensive view of the food and beverage landscape, spanning across the latest health and nutrition trends and industry innovations in ingredients, recipe formulations, food science, sustainability, packaging, and automation, as well as advancements in agri and food-tech.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

PROCESSING AND PACKAGING<br />

49<br />

quickly according to consumer<br />

requirements and to make the best<br />

possible use of capacities. The<br />

GEA DICON inline blender is one of<br />

the workhorses in the production<br />

area, which can also be used to<br />

produce soft drinks, for example.<br />

MULTI-FEATURED FILLER<br />

Pittsburgh Brewing also opted for<br />

a multifunctional filling unit: The<br />

combined rinser-filler-capper block<br />

GEA Visitron ALL-IN-ONE allows for<br />

enhanced flexibility and reliability in<br />

the production of small and medium<br />

volumes. With its very small footprint,<br />

it rinses, fills, seals and seams cans<br />

and glass bottles using 64 filling<br />

heads. Brewers can switch between<br />

different bottle and can formats<br />

in as little as 20-30 minutes.<br />

common diatomaceous earth<br />

filtration and cross-flow filtration<br />

with polymer membranes, Pittsburgh<br />

Brewing has invested in the GEA<br />

clearamic BeerFiltration solution.<br />

The plant works based on the<br />

cross-flow principle and is equipped<br />

with pressure-resistant, inert<br />

and extremely durable ceramic<br />

membranes proven in yeast<br />

recovery and fruit juice filtration.<br />

GEA was the first to adapt this<br />

waste-free process for beer filtration.<br />

This technology allows brewers to<br />

transform the complex and originally<br />

cost-intensive filtration step in the<br />

cold area into a cost-effective and<br />

environmentally friendly process. FBA<br />

Images: GEA<br />

WASTE-FREE FILTRATION WITH<br />

CERAMIC FILTERS<br />

Pale lager beers need to be filtered<br />

to achieve a longer shelf life and the<br />

desired clear, lustrous appearance.<br />

As a sustainable alternative to<br />

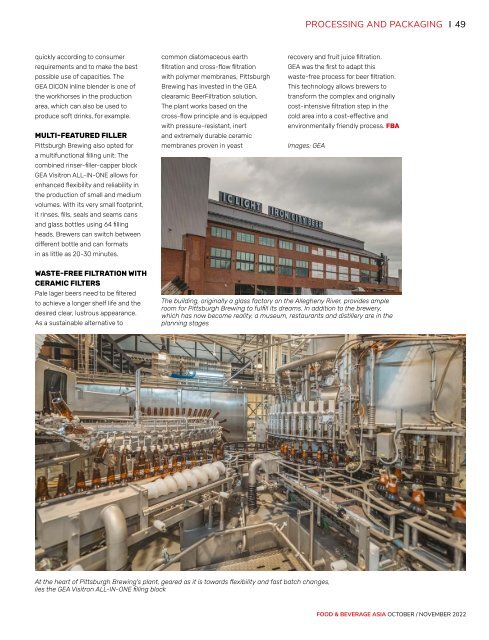

The building, originally a glass factory on the Allegheny River, provides ample<br />

room for Pittsburgh Brewing to fulfill its dreams. In addition to the brewery,<br />

which has now become reality, a museum, restaurants and distillery are in the<br />

planning stages<br />

At the heart of Pittsburgh Brewing's plant, geared as it is towards flexibility and fast batch changes,<br />

lies the GEA Visitron ALL-IN-ONE filling block<br />

FOOD & BEVERAGE ASIA OCTOBER / NOVEMBER <strong>2022</strong>