November 2022

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

NFRC Roofing Talk<br />

CHECK YOUR TIMBER BATTENS<br />

Gary Walpole, NFRC’s Health, Safety and Environment Officer, explains why roofers<br />

must never compromise on quality or safety when it comes to battens, and points out<br />

what to look out for when choosing fully graded roofing battens.<br />

Due to the high demand for treated timber,<br />

compounded by the shortages created by<br />

conflict in Ukraine, the UK’s exit from the<br />

EU, and the COVID-19 pandemic, it is transpiring<br />

that there is a large volume of imported product<br />

that is falsely stamped as BS 5534 or has been<br />

dyed a different colour and then marketed and sold<br />

as compliant material. Using battens that are noncompliant<br />

does not necessarily mean a cost saving<br />

for the contractor or the end user, as suppliers of<br />

non-compliant battens are actually selling them for<br />

the same price as compliant battens.<br />

These inferior products will all have an impact on<br />

the life expectancy of the roofs, but more<br />

importantly it raises the concern for the health<br />

and safety of the operatives using them.<br />

There are also concerns that some roofers have<br />

become complacent – if they believe they have<br />

purchased pre-graded material they will often<br />

use it without inspecting it, and this could be a<br />

critical factor to their safety on the roof.<br />

Battens supplied and fixed in accordance with<br />

BS 5534 are designed to have adequate strength<br />

to support the dead load imposed and wind loads<br />

on roofs clad with tiles or slates, and may be<br />

used as an alternative to roof ladders in line with<br />

current guidance in the Health and Safety<br />

Executive’s HSG 33 Health and Safety in Roof<br />

work and INDG 284 Working on Roofs.<br />

The use of inferior battens that do not comply<br />

with BS 5534 has the potential to cause roof<br />

failures and accidents. This risk of accidents<br />

increases when the roof battens are being used<br />

as an alternative to a roof ladder and are<br />

therefore taking the additional live load of the<br />

operative installing the roof. HSE guidance – HSG<br />

33 Health and Safety in Roof Work – states that<br />

battens must be a minimum size of 50mm x<br />

25mm (maximum span 600mm) or<br />

38mm x 25mm (maximum span<br />

450mm) and meet the grading<br />

requirements specified in BS 5534:<br />

Code of practice for slating and tiling and<br />

NFRC Technical Bulletin 33: Graded battens for<br />

slating and tiling.<br />

Non-compliant battens should not be installed.<br />

Ungraded battens may prove weak and vulnerable<br />

to failure should the roofer inadvertently walk on<br />

these areas whilst covering the roof, potentially<br />

putting roofing operatives at harm. There is also<br />

the issue of quality assurance of the whole roof<br />

system and the impact using inferior battens<br />

could have on the longevity of the roof.<br />

What to look out for:<br />

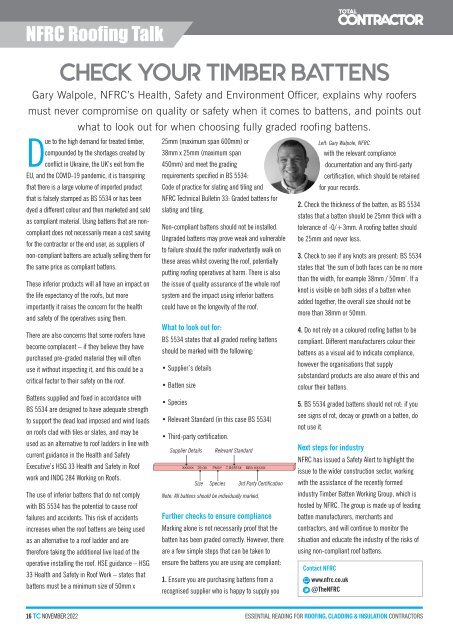

BS 5534 states that all graded roofing battens<br />

should be marked with the following:<br />

• Supplier’s details<br />

• Batten size<br />

• Species<br />

• Relevant Standard (in this case BS 5534)<br />

• Third-party certification.<br />

Supplier Details<br />

Relevant Standard<br />

Size Species 3rd Party Certification<br />

Note: All battens should be individually marked.<br />

Further checks to ensure compliance<br />

Marking alone is not necessarily proof that the<br />

batten has been graded correctly. However, there<br />

are a few simple steps that can be taken to<br />

ensure the battens you are using are compliant:<br />

1. Ensure you are purchasing battens from a<br />

recognised supplier who is happy to supply you<br />

Left: Gary Walpole, NFRC.<br />

with the relevant compliance<br />

documentation and any third-party<br />

certification, which should be retained<br />

for your records.<br />

2. Check the thickness of the batten, as BS 5534<br />

states that a batten should be 25mm thick with a<br />

tolerance of -0/+3mm. A roofing batten should<br />

be 25mm and never less.<br />

3. Check to see if any knots are present: BS 5534<br />

states that ‘the sum of both faces can be no more<br />

than the width, for example 38mm / 50mm’. If a<br />

knot is visible on both sides of a batten when<br />

added together, the overall size should not be<br />

more than 38mm or 50mm.<br />

4. Do not rely on a coloured roofing batten to be<br />

compliant. Different manufacturers colour their<br />

battens as a visual aid to indicate compliance,<br />

however the organisations that supply<br />

substandard products are also aware of this and<br />

colour their battens.<br />

5. BS 5534 graded battens should not rot: if you<br />

see signs of rot, decay or growth on a batten, do<br />

not use it.<br />

Next steps for industry<br />

NFRC has issued a Safety Alert to highlight the<br />

issue to the wider construction sector, working<br />

with the assistance of the recently formed<br />

industry Timber Batten Working Group, which is<br />

hosted by NFRC. The group is made up of leading<br />

batten manufacturers, merchants and<br />

contractors, and will continue to monitor the<br />

situation and educate the industry of the risks of<br />

using non-compliant roof battens.<br />

Contact NFRC<br />

www.nfrc.co.uk<br />

@TheNFRC<br />

16 TC NOVEMBER <strong>2022</strong>